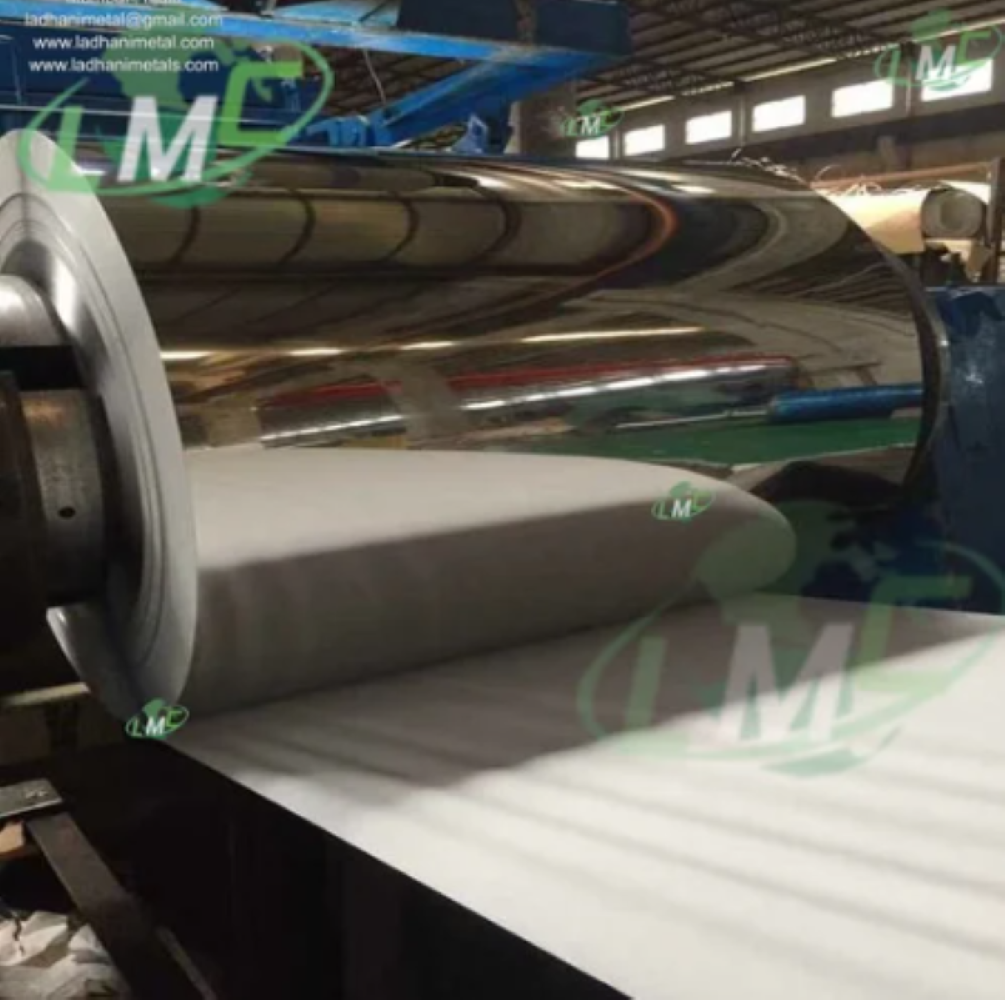

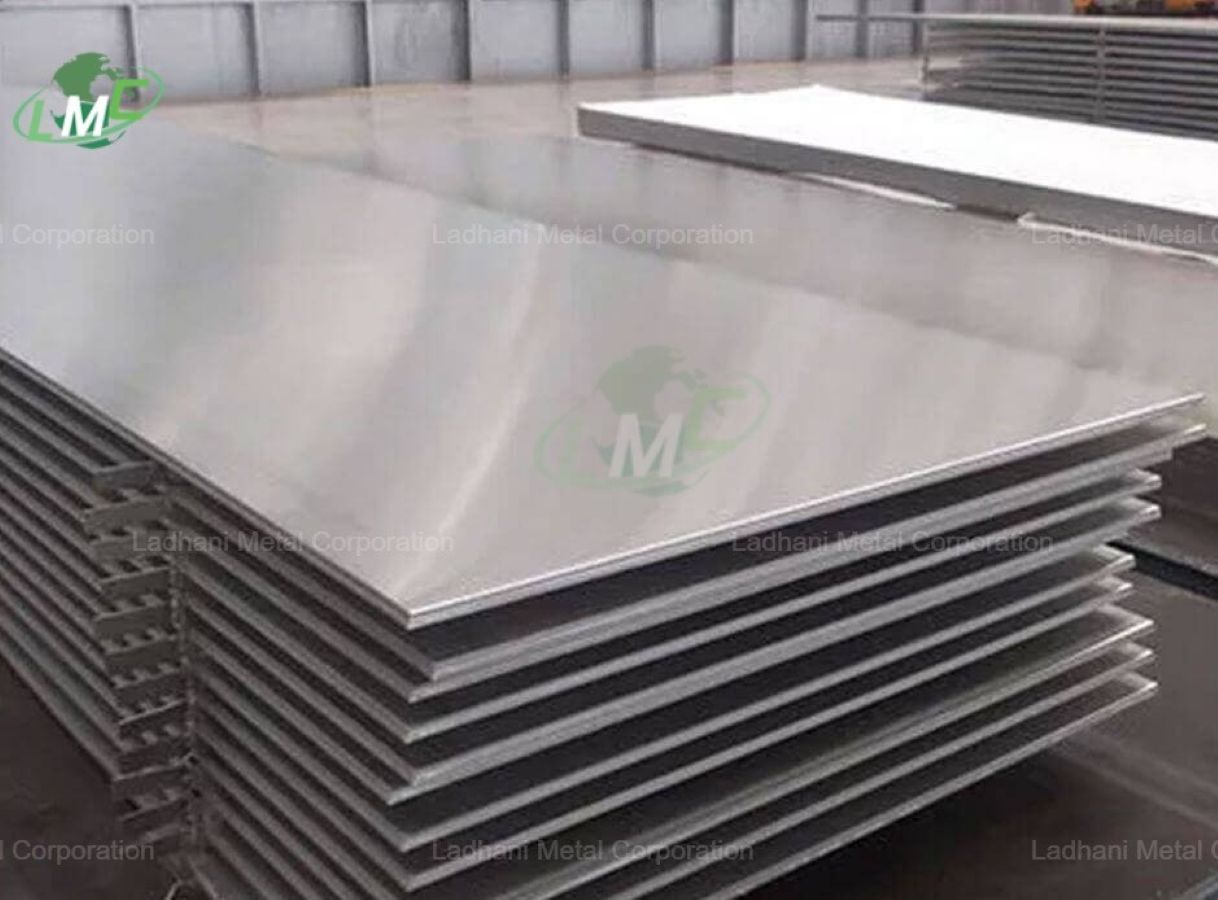

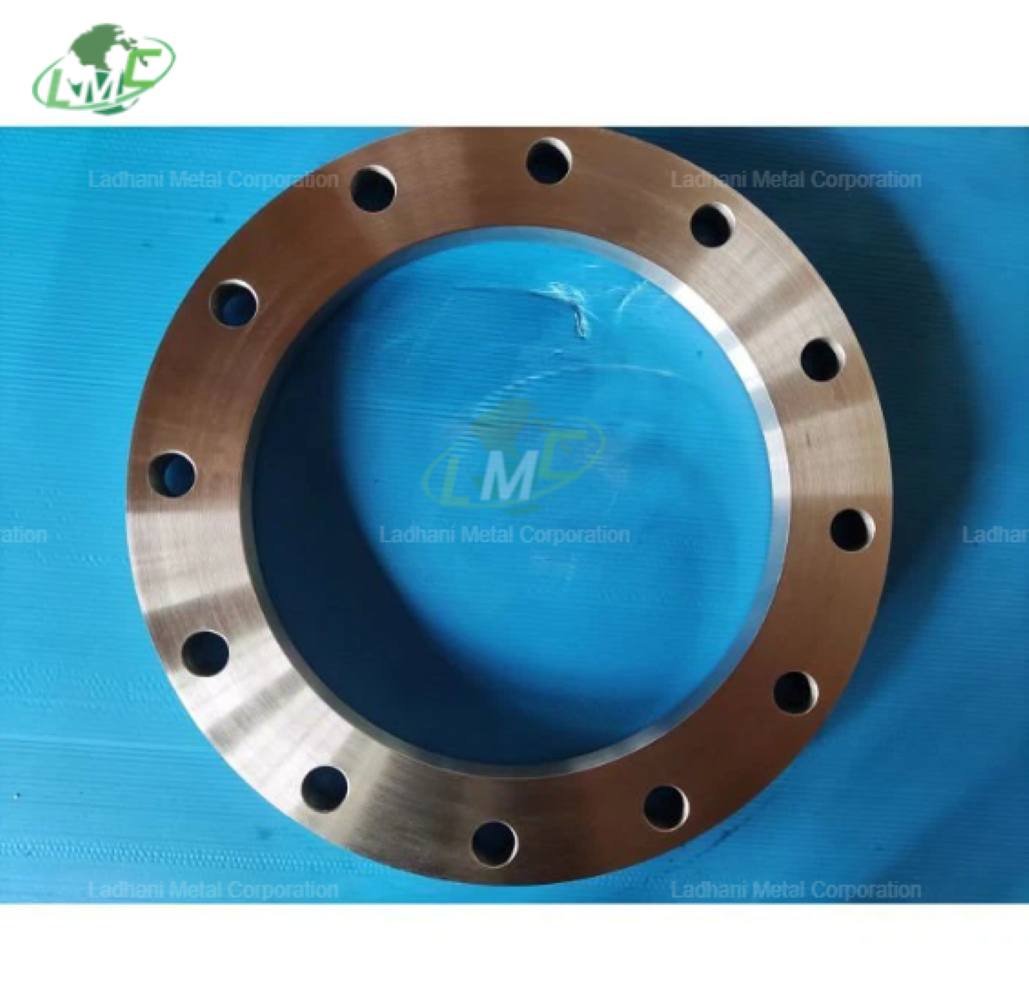

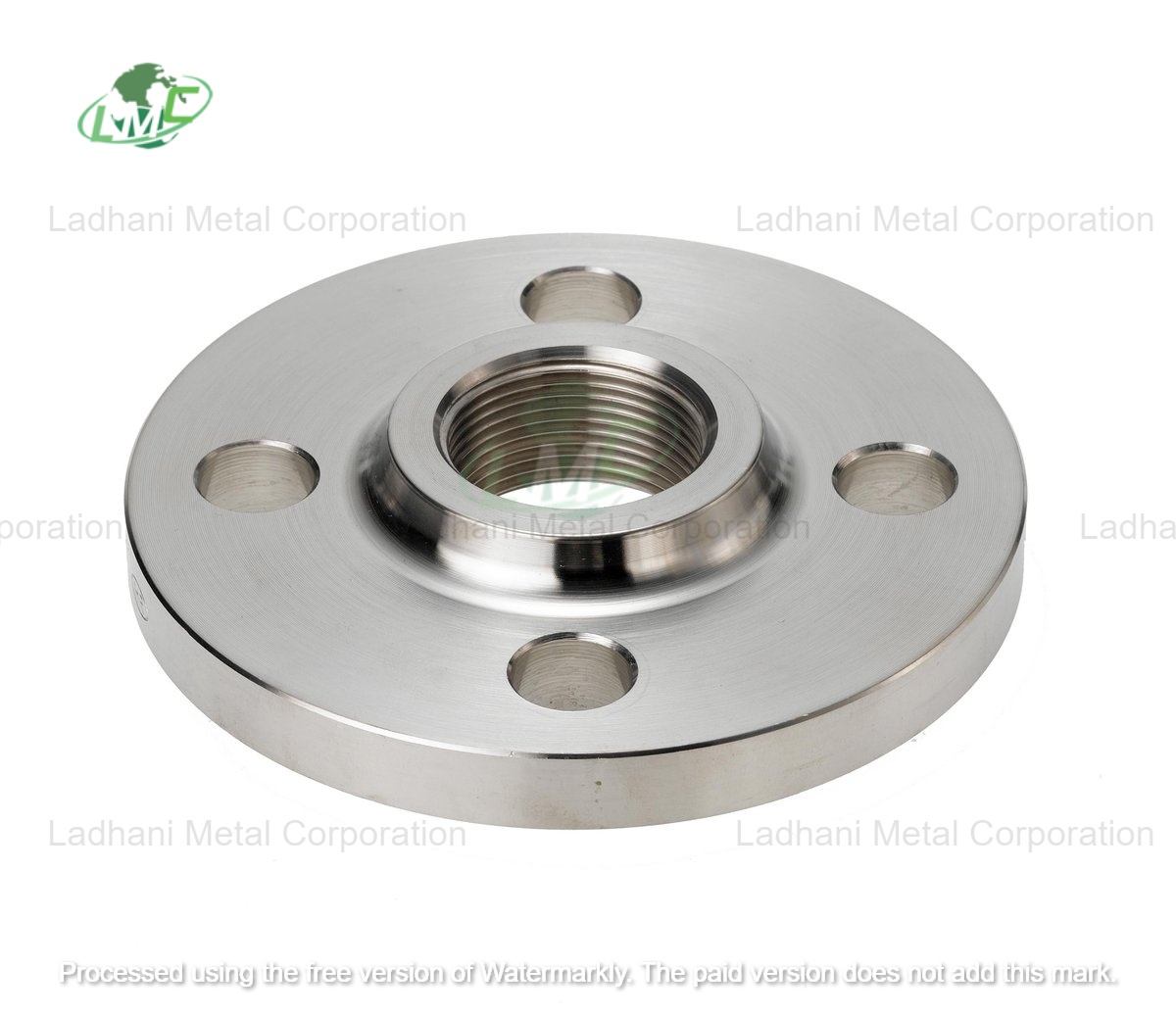

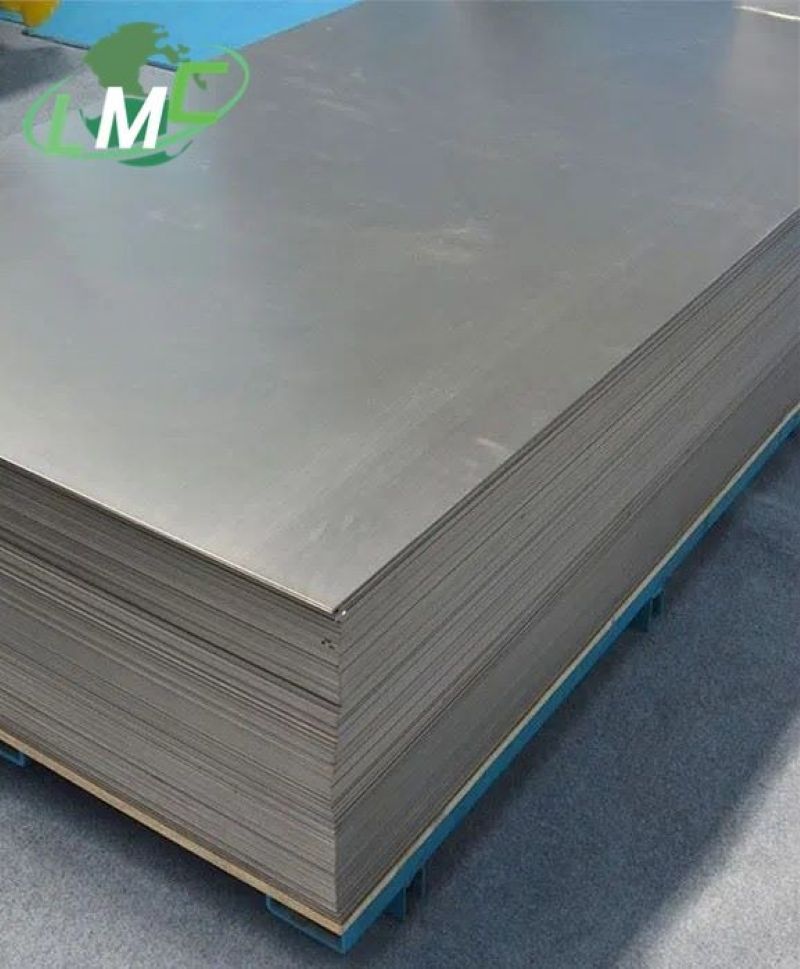

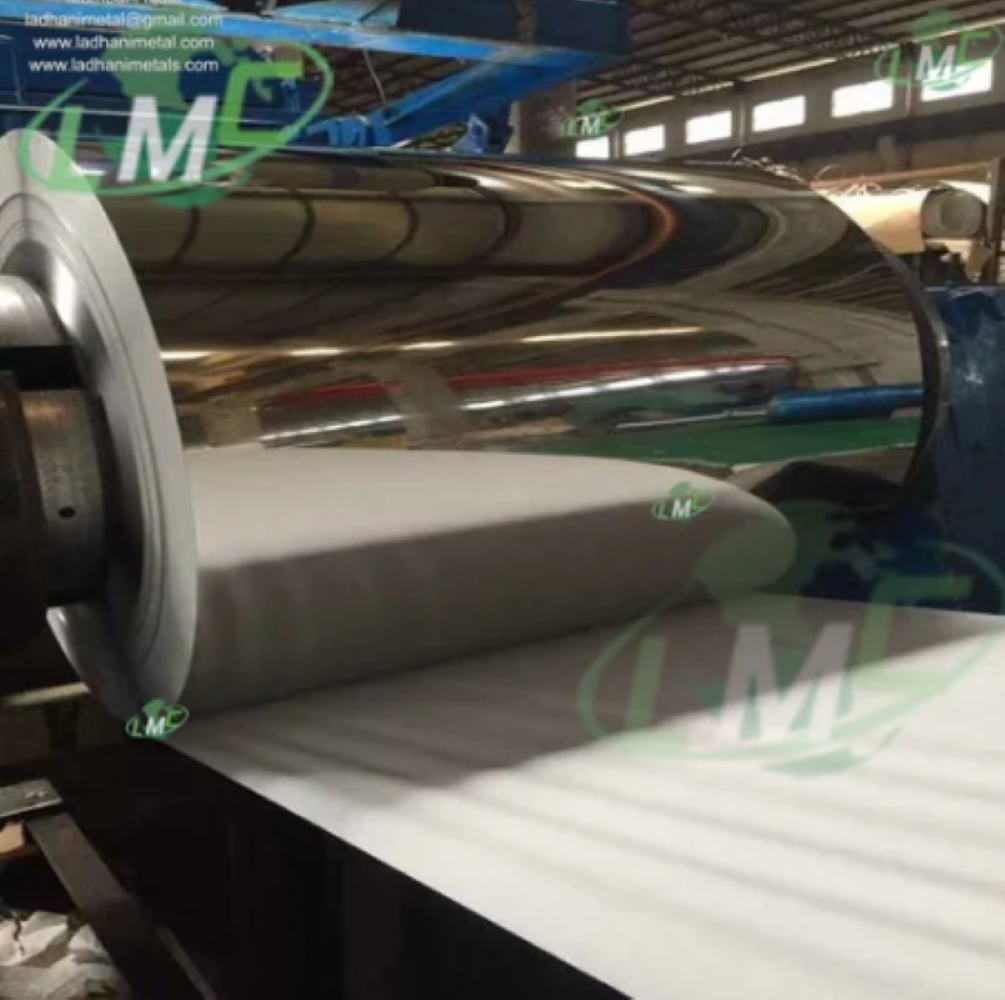

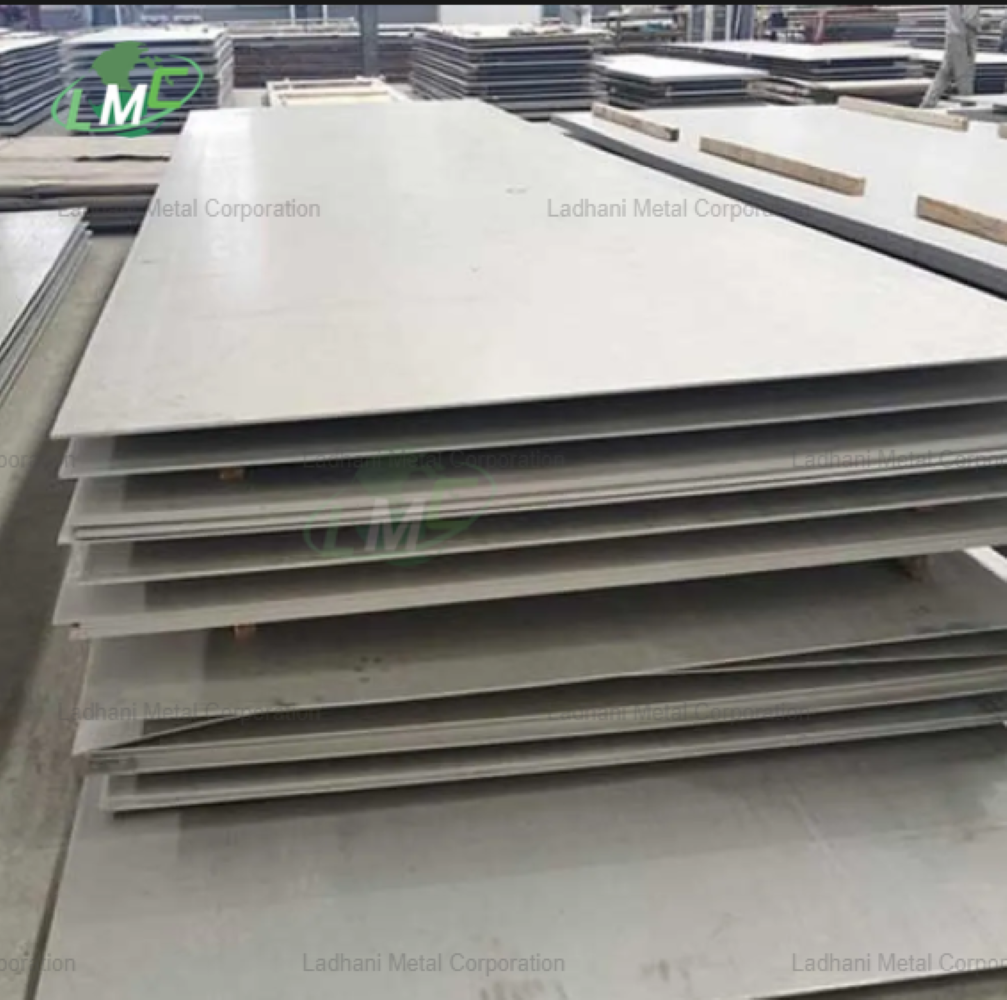

EN 10088 SS X2CrNiN18-7 is an austenitic stainless steel grade known for its enhanced strength, excellent corrosion resistance, and superior formability. It contains chromium, nickel, and nitrogen as key alloying elements that improve its mechanical properties and resistance to pitting, intergranular, and stress corrosion cracking. Ladhani Metal Corporation is a renowned manufacturer, supplier, and exporter of EN 10088 SS X2CrNiN18-7 Coil, along with Sheet, Plate, and Strip. Our stainless steel coils are manufactured using premium raw materials and precision rolling techniques to ensure consistent mechanical properties, excellent surface finish, and dimensional accuracy. These coils are widely used in industries such as chemical processing, construction, automotive, and food production. Forms Available: coil, sheet, plate, strip Chemical Composition (%): • Carbon (C): ≤ 0.03 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 2.00 • Phosphorus (P): ≤ 0.045 • Sulphur (S): ≤ 0.015 • Chromium (Cr): 17.0 – 19.0 • Nickel (Ni): 6.0 – 8.0 • Nitrogen (N): 0.10 – 0.25 Mechanical Properties: • Tensile Strength: 550 – 750 MPa • Yield Strength (0.2% Proof): ≥ 300 MPa • Elongation: ≥ 40% • Hardness (HB): ≤ 215 Key Features: • Enhanced strength and toughness due to nitrogen alloying • Excellent resistance to corrosion and oxidation • Superior formability and weldability • Maintains mechanical integrity at elevated temperatures • Hygienic and smooth surface finish suitable for food and pharmaceutical industries Material Characteristics: EN 10088 SS X2CrNiN18-7 Coil offers a balanced combination of mechanical strength and corrosion resistance. The nitrogen addition significantly enhances yield strength and improves resistance to sensitization and pitting corrosion in chloride environments. The alloy maintains its austenitic structure, ensuring excellent toughness even at cryogenic temperatures. It is easily formed, welded, and fabricated, making it suitable for complex components and structural parts exposed to demanding service conditions. Applications: • Food and beverage processing equipment • Chemical and petrochemical plants • Architectural and structural components • Automotive exhaust and trim parts • Pressure vessels and storage tanks Conclusion: Ladhani Metal Corporation provides premium-quality EN 10088 SS X2CrNiN18-7 Coil, Sheet, Plate, and Strip that deliver exceptional performance, durability, and corrosion resistance. Manufactured to meet international standards, our stainless steel products are available in various sizes, tempers, and finishes. For further technical information, customized specifications, or bulk inquiries, please contact Ladhani Metal Corporation – your reliable partner for high-performance stainless steel solutions. #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar #EN10088 #EN10088StainlessSteel #En10088SheetPlateCoilStrip #SSSheet #SSPlate #SSCoil #SSStrip #ColdRolledSteel #HotRolledSteel #CustomFabrication #CorrosionResistantSteel #DurableSteel #PrecisionEngineered #EN10088SSManufacturer #EN10088SSSupplier #EN10088SSExporter #ISOApproved #InternationalGradeSteel #HighPerformanceSteel #IndustrialSheet #IndustrialPlate #IndustrialCoil #IndustrialStrip #StainlessSteelSupplier #StainlessSteelManufacturer #StainlessSteelExporter #MetalFabrication #IndustrialApplications #ConstructionMaterials #EngineeringMaterials #OEMApplications #LadhaniMetals #MetalSupplier #MetalExporter #SteelIndustry #MarineSteelApplications #AutomotiveSteelApplications #ChemicalProcessingSteel #FoodProcessingSteel #PharmaGradeSteel #PowerGenerationSteel #HeatExchangerSteel #WaterTreatmentSteel #ArchitecturalSteel #IndustrialEquipmentSteel #CustomMetalSolutions #GlobalExporter #IndianManufacturer #TechnicalSpecifications #MaterialStandards #SteelFabricator #IndustrialSupplier #StainlessSteelIndia #StainlessSteelExporters #IndustrialMetals #MetalSheets #MetalPlates #MetalCoils #MetalStrips #SheetMetalProcessing #SteelFabrication #EngineeringProjects #OEMMetalSolutions #HighQualitySteel #LongLifeMaterial #FabricationMaterials #IndustrialSteel #StainlessSteelProducts