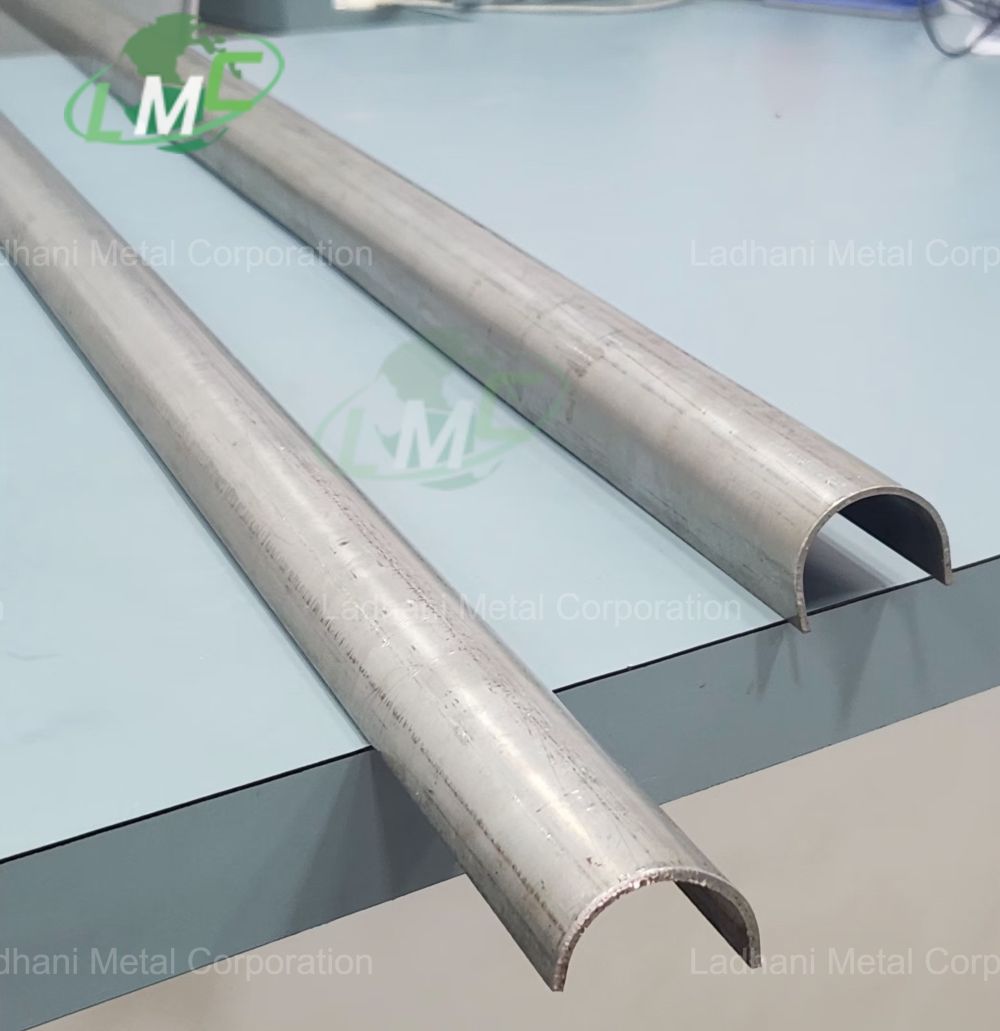

Ladhani Metal Corporation offers Stainless Steel Half Round Tube Shields designed to protect boiler tubes from erosion, corrosion, oxidation, and mechanical wear in power plants, refinery heaters, waste heat recovery boilers (WHRBs), and heat recovery steam generators (HRSGs). These shields are semi-cylindrical tube covers fitted over vulnerable sections of boiler tubes to prevent premature thinning caused by high-velocity flue gases, abrasive ash particles, and soot blower impact. By acting as a sacrificial protective layer, Stainless Steel Half Round Tube Shields significantly extend tube service life and improve boiler reliability. Function of Tube Shields • Protect boiler tubes from erosion, corrosion, and scaling • Reduce tube wear in high-temperature and high-flow zones • Minimize shutdowns and maintenance costs • Extend overall efficiency and durability of the boiler system Ladhani Metal Corporation manufactures, supplies, and exports Stainless Steel Half Round Tube Shields in a wide range of standard and custom specifications to meet domestic and international project requirements. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Extensively used in thermal power plants, waste heat recovery units, refinery heaters, petrochemical furnaces, HRSGs, and industrial boilers operating in erosive and corrosive environments. Uses • Protects boiler tubes against flue gas erosion and oxidation • Shields reheater and superheater tubes in high-temperature zones • Guards economizer and LTSH sections from ash erosion • Extends operational life in refinery and process heaters Features • Excellent corrosion and oxidation resistance at elevated temperatures • High mechanical strength and durability under cyclic heating • Precision-engineered for accurate fit over tube diameter • Easy installation, removal, and replacement during maintenance Applications • Power generation boilers – Tube protection in superheaters and reheaters • HRSGs – Reliable under frequent thermal cycling • Waste heat recovery boilers – Protection against abrasive and corrosive flue gases • Refinery and petrochemical heaters – Enhanced durability in aggressive atmospheres Conclusion Stainless Steel Half Round Tube Shields for Boilers from Ladhani Metal Corporation are engineered to provide superior protection against erosion, corrosion, and oxidation in demanding boiler environments. Manufactured in stainless steels and heat-resistant alloys, these shields ensure long service life, reduced downtime, and export-ready quality for global energy and industrial applications. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Muzaffarpur#halftubeshield #utypehalftubeshield #tubeshieldexporter #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #HalfRoundReheaterShield #ReheaterTubeShield #BoilerReheaterProtection #PowerPlantTubeShield #BoilerErosionShield #SteamBoilerTubeShield #HighTempTubeShield #BoilerWearProtection

Send Message