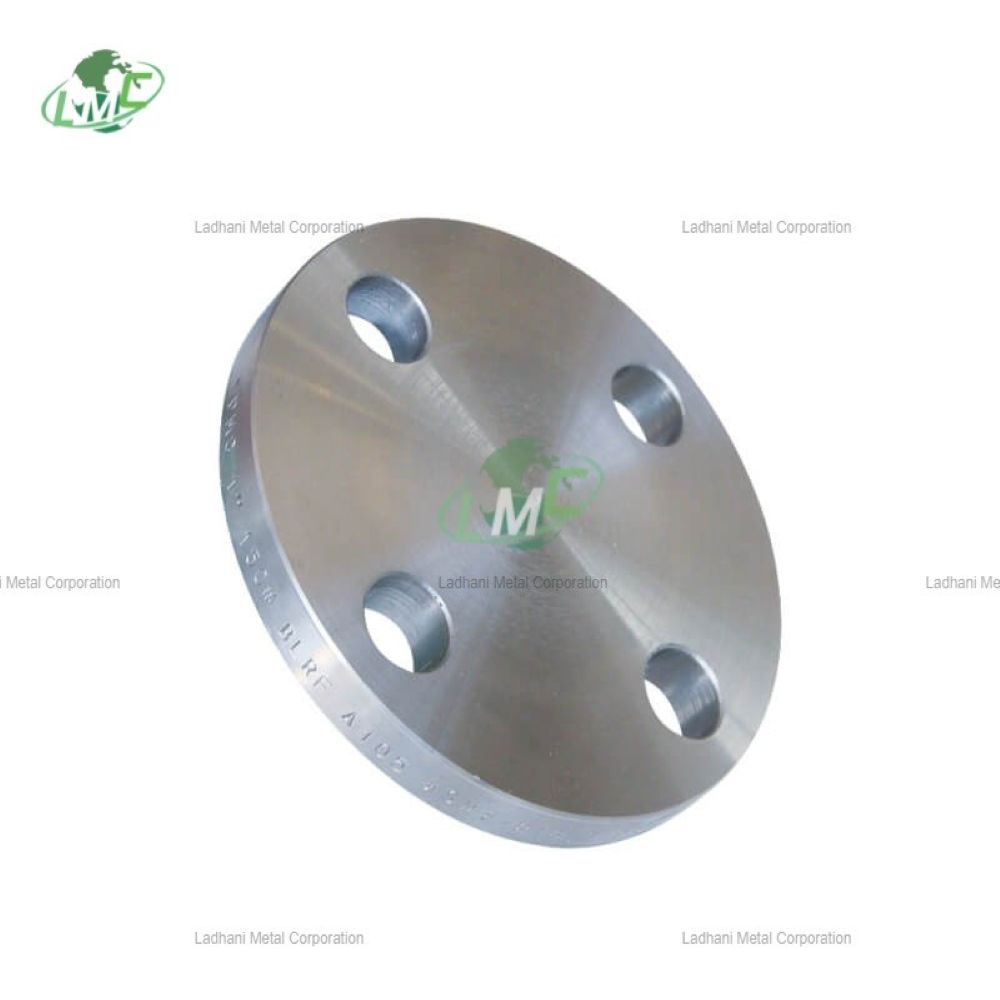

DIN 2545 Inconel flanges are engineered for superior strength, excellent resistance to high temperatures, and remarkable corrosion resistance in extreme environments. Ladhani Metal Corporation provides these high-quality flanges made from Inconel alloys, known for their ability to endure elevated temperatures, oxidation, and corrosive conditions. These flanges are ideal for industries where performance under high-temperature stress and resistance to harsh environments are essential, such as aerospace, chemical processing, power generation, and marine. Types of DIN 2545 Inconel Flanges: Flat Face Flanges (FF) – These flanges have a flat surface that facilitates uniform distribution of the sealing force, making them ideal for low-pressure systems or when a secure seal is required. Raised Face Flanges (RF) – Raised face flanges feature a raised area around the bolt holes, providing enhanced sealing pressure, making them suitable for high-pressure environments. Ring-Type Joint (RTJ) Flanges – Designed with a groove for a metal sealing ring, these flanges are ideal for applications requiring resistance to high pressure and high temperatures. Grades and Chemical Composition: Inconel 600 (UNS N06600) Chemical Composition: Ni: 72%, Cr: 14-17%, Fe: balance, Mn: 1%, Si: 0.5%, C: 0.15% Inconel 600 is known for its excellent resistance to oxidation and corrosion at elevated temperatures. It is widely used in applications like furnace components, chemical processing, and nuclear reactors, offering high strength and good workability. Inconel 625 (UNS N06625) Chemical Composition: Ni: 58%, Cr: 20-23%, Mo: 8-10%, Fe: 5%, Nb: 3.15-4.15%, Ti: 0.4-1% Inconel 625 is a nickel-based alloy that offers superior resistance to high-temperature oxidation and corrosion. It provides exceptional resistance to pitting and crevice corrosion, making it ideal for applications in aerospace, marine, and chemical industries, where high temperatures and corrosive environments are common. Inconel 718 (UNS N07718) Chemical Composition: Ni: 50-55%, Cr: 17-21%, Fe: 0-5%, Mo: 2.8-3.3%, Nb+Ta: 4.75-5.5%, Ti: 0.65-1.15%, Al: 0.2-0.8% Inconel 718 is a high-strength, corrosion-resistant alloy widely used in high-temperature applications. It is designed for use in extreme conditions, offering excellent resistance to oxidation, sulfidation, and high-temperature environments. PN 40 Pressure Rating: The "PN" rating indicates the flange's pressure capacity. PN 40 refers to flanges that are designed to withstand pressures up to 40 bar, making them suitable for high-pressure systems where secure, leak-free connections are essential. Applications: Aerospace Industry: Jet Engines and Turbomachinery: Inconel flanges are commonly used in aerospace applications, including jet engines and turbine systems, where components are exposed to extremely high temperatures and pressures. They provide excellent resistance to heat and corrosion in high-stress environments. Exhaust Systems: Inconel's ability to withstand high temperatures makes it ideal for use in exhaust systems of aircraft engines. 2. Power Generation Industry: Gas Turbines: Inconel flanges are used in gas turbines in power plants, particularly in components that operate at high temperatures, such as turbine blades, combustors, and other critical parts. Nuclear Power Plants: Inconel is used in the construction of components for nuclear reactors, where heat and radiation resistance are crucial. It is used in piping, valves, and other systems exposed to high-temperature nuclear environments. 3. Chemical Processing and Petrochemical Industries: High-Temperature Reactors: Inconel flanges are used in reactors, heat exchangers, and other equipment in the chemical industry that handle aggressive, high-temperature chemical reactions, including those with sulfuric acid, chlorine, and other corrosive substances. Petrochemical Refineries: Inconel is used in systems where high temperatures and reactive chemicals are present, offering superior performance in handling corrosive materials such as acids and hydrocarbons. 4. Oil and Gas Industry: Offshore Platforms: Inconel flanges are widely used in offshore oil and gas platforms, particularly in subsea pipelines, risers, and pressure vessels, where high resistance to both high pressure and corrosion (especially from seawater) is necessary. Wellhead Equipment: Inconel flanges are also used in downhole equipment and wellhead connections that need to resist high-pressure environments and exposure to extreme temperatures. Ladhani Metal Corporation ensures that each Inconel flange is produced to the highest standards of quality and precision, adhering to international specifications. Every flange undergoes thorough testing to meet the required durability and performance standards, providing reliable solutions for critical applications in the most challenging environments. #din2545 #din2545flanges #din2545inconelflanges #flanges #flangessupplier