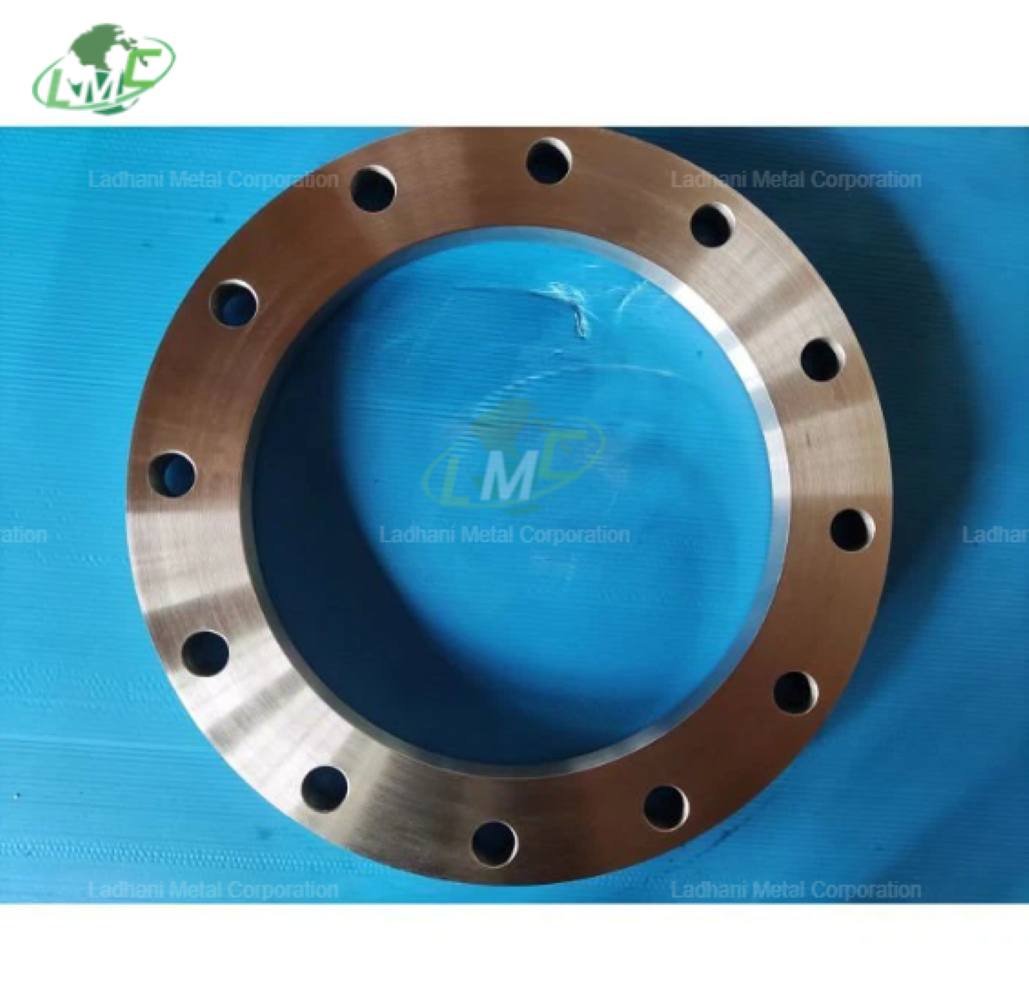

DIN 2576 Inconel Flanges PN 10 are high-performance, slip-on flanges engineered from nickel-chromium-based superalloys designed for use in corrosive and high-temperature industrial environments. Manufactured to the DIN 2576 standard, these flanges are well-suited for low to medium-pressure applications requiring exceptional resistance to oxidation, thermal stress, and chemical attack. The slip-on design allows the flange to slide over the pipe and be welded in place, providing accurate alignment and strong mechanical stability. Ladhani Metal Corporation is a trusted manufacturer and exporter of Inconel flanges, offering precision-engineered components that meet international quality and dimensional standards. DIN 2576 Inconel flanges are ideal for challenging applications in aerospace, chemical processing, power generation, and marine systems. Pressure Rating: • PN 10 (10 bar / 145 psi): Suitable for low to moderate pressure operations, delivering reliable sealing and long-term performance in fluid and gas transport systems. Flange Types: • Slip-On Flanges Designed to fit over the pipe and be welded on both sides, offering simplified installation and secure mechanical performance. • Flat Face (FF) Flanges Used with flat gaskets and mating surfaces, providing uniform gasket compression and sealing integrity, especially with brittle or non-metallic components. Inconel Grades and Composition: Inconel 600 (UNS N06600) Composition: • Nickel (Ni): ≥ 72.0% • Chromium (Cr): 14.0 – 17.0% • Iron (Fe): 6.0 – 10.0% • Trace elements: Manganese, Silicon, Copper Applications: Inconel 600 offers excellent resistance to high-temperature oxidation, chloride-ion stress corrosion cracking, and acidic environments. Commonly used in furnace components, chemical process heaters, and nuclear reactors. Inconel 625 (UNS N06625) Composition: • Nickel (Ni): ≥ 58.0% • Chromium (Cr): 20.0 – 23.0% • Molybdenum (Mo): 8.0 – 10.0% • Niobium (Nb) + Tantalum (Ta): 3.15 – 4.15% Applications: Inconel 625 is known for its outstanding corrosion resistance in harsh conditions, including seawater, acid baths, and high-pressure environments. It is used extensively in marine hardware, offshore oil and gas systems, and aerospace exhaust systems. Inconel 718 (UNS N07718) Composition: • Nickel (Ni): 50.0 – 55.0% • Chromium (Cr): 17.0 – 21.0% • Iron (Fe): Balance • Niobium (Nb): 4.75 – 5.5% • Molybdenum (Mo): 2.8 – 3.3% • Titanium (Ti) + Aluminum (Al): ~1% Applications: Inconel 718 is a high-strength, precipitation-hardenable alloy with excellent corrosion and oxidation resistance. It performs well in cryogenic to high-temperature environments and is widely used in jet engines, high-temperature bolting, power generation turbines, and downhole oil and gas equipment. Applications of DIN 2576 Inconel Flanges: • Chemical and Petrochemical Processing Ideal for use in systems handling strong acids, solvents, and oxidizing agents at elevated temperatures. • Power Generation Used in heat exchangers, boiler systems, and turbine piping exposed to thermal cycling and steam corrosion. • Marine and Offshore Industries Excellent choice for seawater-cooled systems, marine risers, and subsea components due to its resistance to pitting and crevice corrosion. • Aerospace and Defense Applied in engine exhausts, combustion chambers, and other high-heat zones requiring structural integrity under extreme conditions. • Nuclear and High-Risk Industrial Systems Reliable in applications with radioactive or caustic media, where corrosion and temperature resistance are critical. Key Features: • Manufactured to DIN 2576 standard • PN 10 pressure rating suitable for moderate-pressure piping systems • Outstanding resistance to corrosion, oxidation, and high temperatures • Available in Inconel 600, 625, and other grades upon request • Slip-on design for ease of welding and proper pipe alignment • Flat face options for compatibility with a variety of gaskets and joint materials • Ideal for harsh chemical, thermal, and marine environments • Custom sizes, face types, and finishes available as per project requirements Conclusion: DIN 2576 Inconel Flanges PN 10 from Ladhani Metal Corporation are engineered for the toughest industrial environments, delivering performance, durability, and corrosion resistance where stainless steel or other materials may fail. For material selection support, technical data sheets, or customized orders, contact Ladhani Metal Corporation today.

Send Message