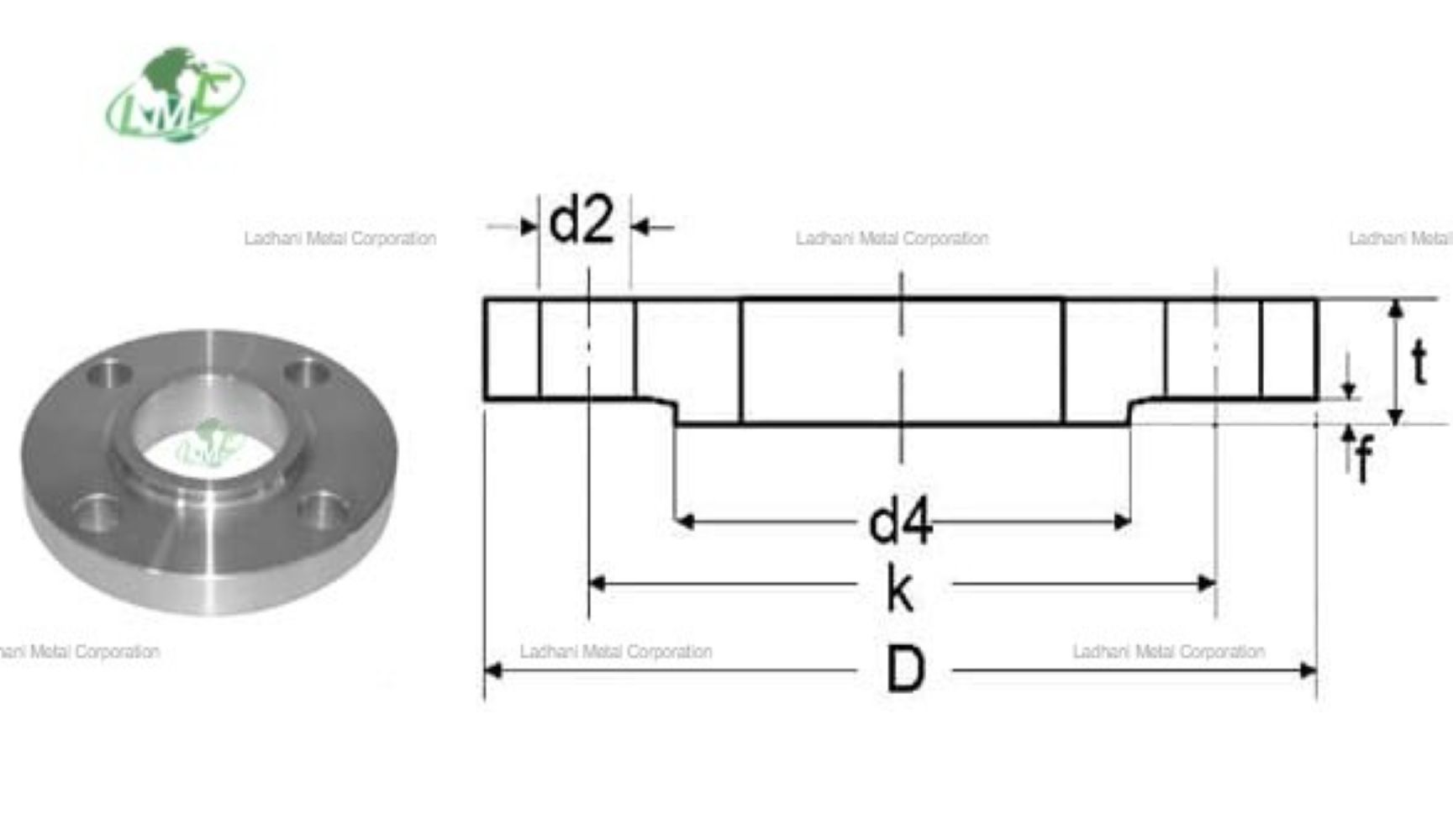

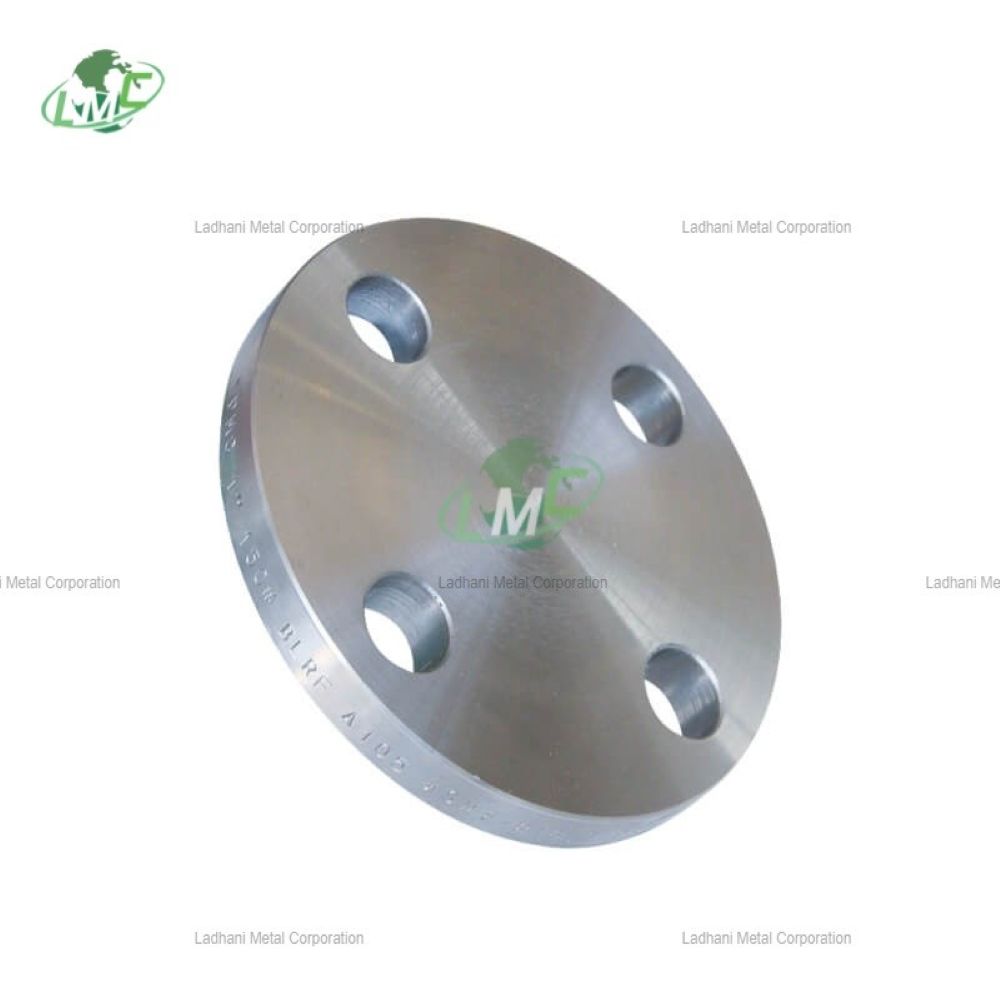

DIN 2543 refers to a standard for titanium flanges under the German DIN (Deutsches Institut für Normung) system. Titanium flanges are designed for use in piping systems, connecting pipes, valves, pumps, and other equipment. They provide a secure method of joining pipes while allowing for easy disassembly when needed. These flanges are made from titanium or titanium alloys, which are known for their strength, corrosion resistance, and lightweight properties. Titanium is particularly advantageous in harsh environments such as marine, chemical processing, and high-temperature systems due to its resistance to oxidation and corrosion. Key Features: Material: Titanium or titanium alloys Corrosion Resistance: Excellent resistance to corrosion in various environments, particularly in acidic or saline conditions. Strength-to-weight ratio: Higher strength-to-weight ratio than steel. Temperature Tolerance: Titanium flanges can handle high temperatures and extreme conditions. Lightweight: Titanium is significantly lighter than steel, making transportation and handling easier. Pressure Rating (PN16):The "PN" (Pressure Nominal) value indicates the maximum pressure the flange can withstand at a specific temperature (typically 20°C).PN16 means the flange is rated for a maximum pressure of 16 bar (or 232 psi). Standard Flange Design: DIN 2543 titanium flanges follow a standardized design which includes: Type: Usually weld neck, slip-on, blind, or socket weld. Size: Flanges come in various sizes with different pressure ratings. Bolt Holes: They have drilled holes for bolts to connect to the mating flange. Face Type: Can be raised face, flat face, or RTJ (Ring Type Joint) depending on the application. Types of Titanium Flanges (According to DIN 2543): Weld Neck Flanges (WN): Ideal for high-pressure systems. Slip-on Flanges (SO): Easy to install, used for general applications. Blind Flanges (BL): Used to seal the end of a pipeline. Socket Weld Flanges (SW): Used for small bore applications. Lap Joint Flanges (LJ): Used with a stub end, providing easier alignment and disassembly Grades of Titanium Used for Flanges: Grade 2 (CP-Titanium - Commercially Pure Titanium): Composition: 99.2% pure titanium. Properties: Excellent corrosion resistance, moderate strength, highly ductile, good weldability. Grade 5 (Ti-6Al-4V - Titanium Alloy): Composition: 90% Titanium, 6% Aluminum, 4% Vanadium. Properties: High strength, excellent corrosion resistance, good fatigue strength, and slightly more difficult to weld. Conclusion: Grade 2 is ideal for applications requiring excellent corrosion resistance and ease of fabrication, while Grade 5 provides superior strength and is used in demanding applications like aerospace and high-performance industrial systems. Both grades offer excellent properties for titanium flanges used in a wide variety of industries. we also deal in various material in DIN2543 such at Stainless steel, duplex, super duplex, Inconel, Monel and carbon steel

Send Message