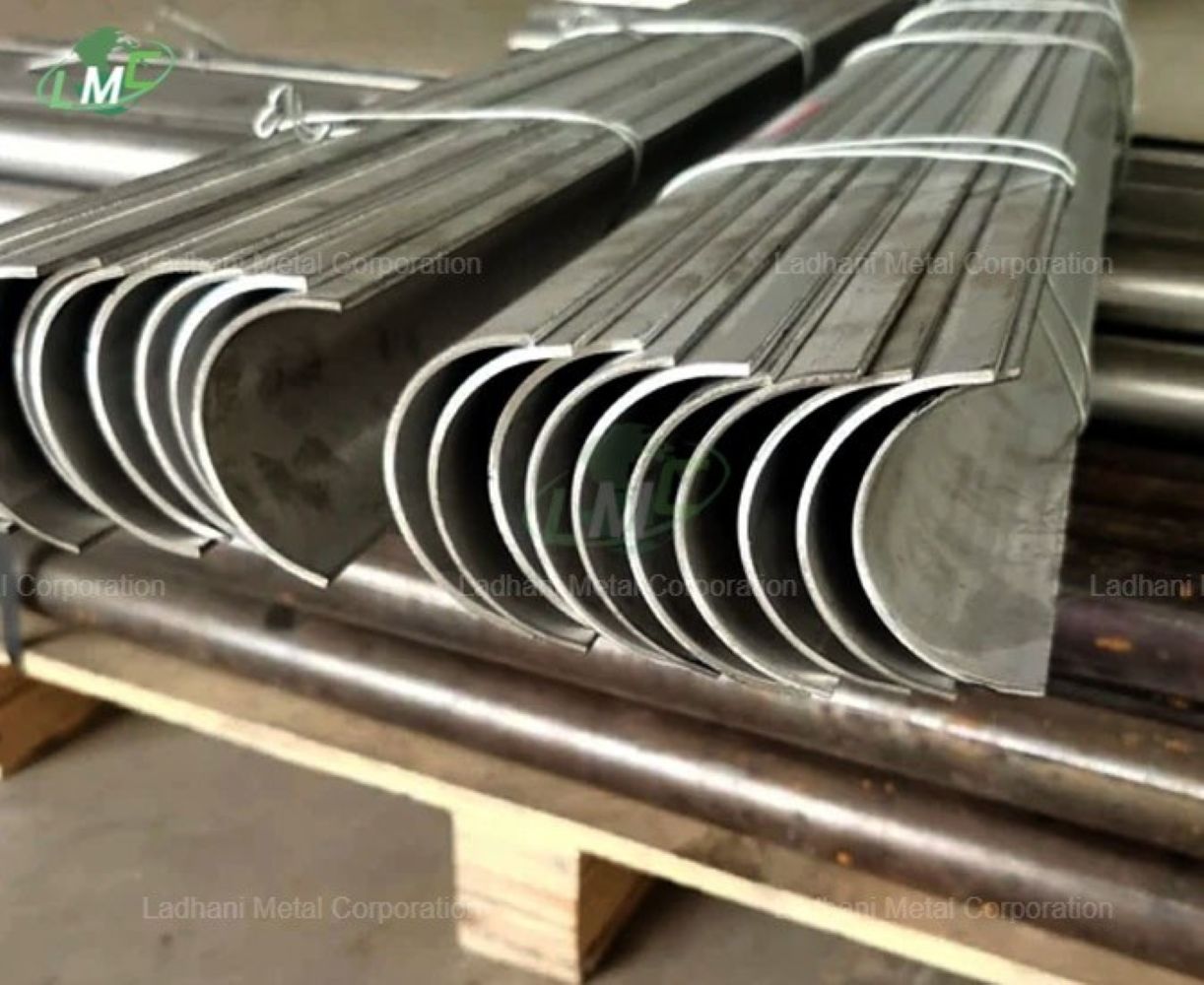

Half Round Tube Shield Ladhani Metal Corporation manufactures Cr25Ni20 Half Round Straight Tube Shields for use in high-temperature industrial environments where resistance to oxidation, carburization, and thermal fatigue is critical. Cr25Ni20 is a heat-resistant alloy with a high chromium (25%) and nickel (20%) content, offering excellent stability under prolonged exposure to high heat and corrosive flue gases. This alloy is widely used in boilers, reformers, waste heat recovery systems, and thermal process units. Cr25Ni20 Half Round Straight Tube Shield The Cr25Ni20 Half Round Straight Tube Shield is precisely shaped to fit the outer surface of straight heat exchanger or boiler tubes. It forms a durable, semi-cylindrical layer of protection against high-temperature scaling, tube thinning, and erosion caused by particulate-laden flue gas. The shield enhances tube longevity in radiation zones and areas prone to direct flame or high-velocity gas flow. Its excellent thermal shock resistance also makes it suitable for cyclic heating and cooling conditions. Ladhani Metal Corporation is a leading manufacturer, supplier, and exporter of Cr25Ni20 Half Round Straight Tube Shields, delivering robust thermal shielding solutions for critical tube protection. Material Grade Cr25Ni20 – High chromium-nickel heat-resistant alloy Chemical Composition of Cr25Ni20 • Carbon (C): ≤ 0.08% • Silicon (Si): ≤ 1.5% • Manganese (Mn): ≤ 2.0% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 19.0 – 22.0% • Iron (Fe): Balance Uses • Protection of boiler tubes in radiant and convection zones • Straight tube shielding in reformers and furnace outlets • High-temperature air and gas heater shielding • Application in coal gasification and petrochemical furnaces • Tube erosion prevention in thermal incineration units Features • Excellent high-temperature performance – Operates reliably above 1000°C • Resistant to oxidation and scale – Maintains surface integrity in oxidizing environments • Superior creep strength – Suitable for long-term service under thermal stress • Effective in carburizing atmospheres – Ideal for furnaces and gas reactors • Thermal fatigue resistance – Withstands repeated heating and cooling cycles • Custom fabrication – Available in multiple lengths, thicknesses, and diameters Applications • power generation boilers – Radiant zone tube protection • thermal cracking units – Resistant to flame impingement and high gas velocity • waste heat recovery boilers – Prolongs tube life in high-ash flue gas areas • fertilizer plants – Used in ammonia reformer tube protection • metallurgical furnaces – Shields exposed tubes in extreme temperature cycles Conclusion Cr25Ni20 Half Round Straight Tube Shields from Ladhani Metal Corporation offer outstanding durability and heat resistance, making them ideal for straight tubes operating in the most demanding high-temperature applications. Their high chromium and nickel content ensures reliable service where oxidation, erosion, and thermal cycling are a concern. For custom sizes, specifications, or technical consultations, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield

Send Message