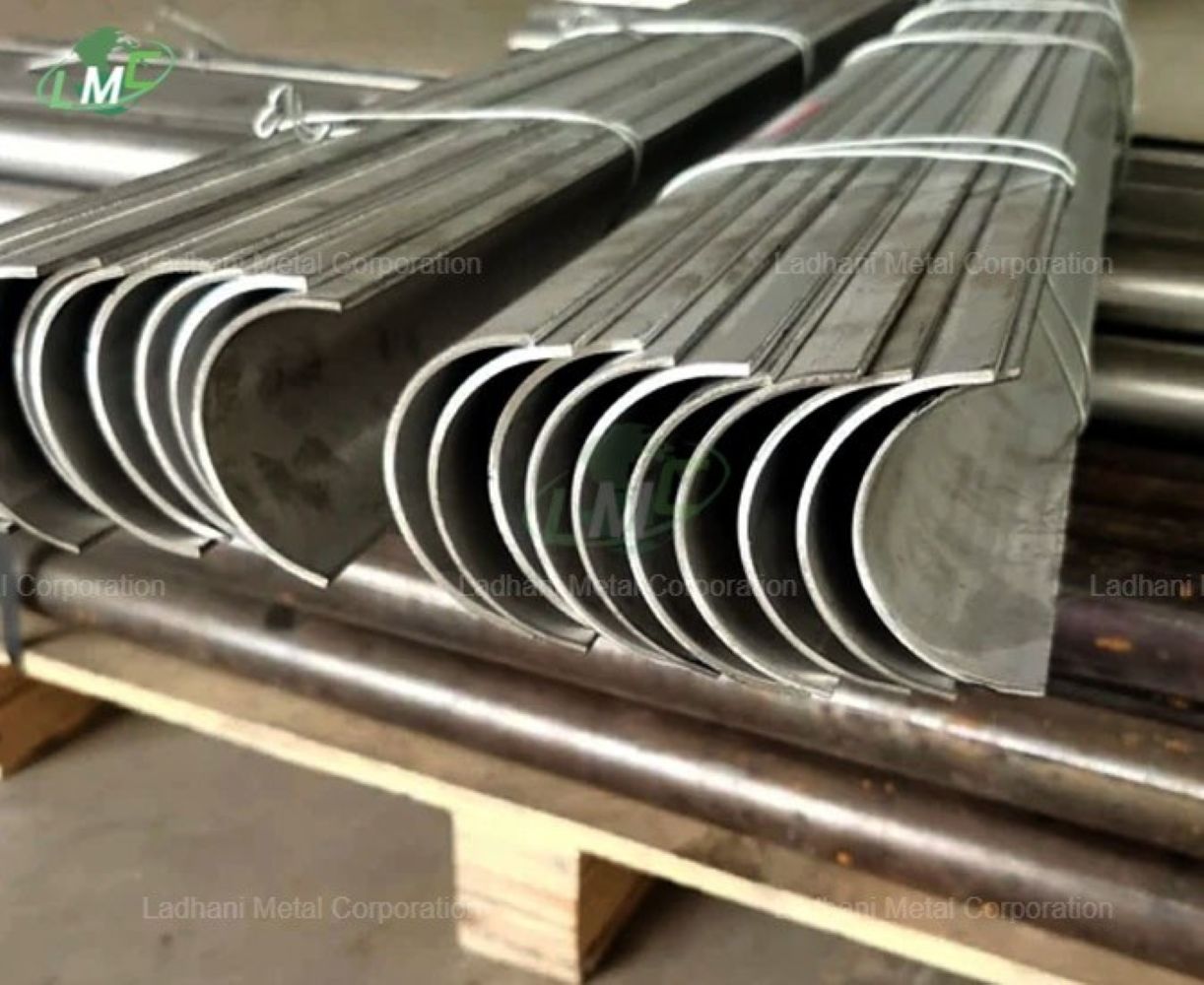

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are precisely engineered components used to safeguard boiler tubes, superheaters, and heat exchanger coils from erosion, scaling, thermal stress, and high-temperature corrosion. Their half-round construction enables quick and secure installation over straight or curved tube surfaces, offering long-term protection and minimizing maintenance in industrial heating systems, power plants, and petrochemical facilities. 1Cr18Ni9Ti U Type Inner Half Round Tube Shield The 1Cr18Ni9Ti U Type Inner Half Round Tube Shield is manufactured from a titanium-stabilized austenitic stainless steel grade, offering superior resistance to intergranular corrosion and oxidation at elevated temperatures. This grade is particularly effective in welded applications and thermal systems subjected to cycling and corrosive media. The inner U-type configuration is designed to shield the inside curvature of U-bend tubes, where turbulent gas flow, slag, and thermal concentration often cause accelerated wear and scaling. • Inner U Type Half Round Tube Shield – Designed to protect the internal arc of U-bend tubes from high-temperature scaling, slag impact, and turbulent gas erosion. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of 1Cr18Ni9Ti U Type Inner Half Round Tube Shields, offering durable, high-performance shielding solutions for critical thermal systems. Chemical Composition of 1Cr18Ni9Ti – Titanium-Stabilized Austenitic Stainless Steel • Carbon (C): ≤ 0.12% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 17.0 – 19.0% • Nickel (Ni): 8.0 – 11.0% • Titanium (Ti): Stabilized as required • Iron (Fe): Balance Applications: Ideal for welded and high-temperature systems exposed to oxidation, intergranular corrosion, and chloride-bearing flue gases. Uses • Protects inner arcs of U-bend tubes in superheaters and reheaters of thermal power plants • Installed in return bends of waste heat recovery boilers (WHRBs) and HRSGs facing slag and scale accumulation • Applied in curved tube sections in chemical reactors and heat exchangers exposed to acidic or oxidizing gases • Suitable for marine and coastal heating systems where chlorides and moisture are present • Used in food processing, metallurgical furnaces, and process plants requiring stable, high-temperature performance Features • Excellent intergranular corrosion resistance – Stabilized with titanium to prevent carbide precipitation • Inner arc protection – Shields high-stress areas from gas turbulence and heat-induced damage • High-temperature performance – Reliable up to 870°C in oxidizing environments • Custom fit – Fabricated to match specific tube diameters and bend radii for precise installation • Easy to install – Suitable for clamp-on, weld-on, or banding methods • Long service life – Reduces frequency of tube replacement and supports consistent thermal performance Applications • thermal power generation – Inner arc protection in U-bend tubes exposed to combustion gases and temperature fluctuations • petrochemical and fertilizer plants – Shields tube bends in reactors and reformers exposed to acidic gases • waste heat recovery – Guards inner surfaces of tube coils in WHRBs and HRSGs from scaling and corrosion • marine heat exchangers – Suitable for use in systems exposed to saltwater vapors and high humidity • industrial furnaces and incinerators – Provides internal bend protection under severe thermal cycling Conclusion The 1Cr18Ni9Ti U Type Inner Half Round Tube Shield by Ladhani Metal Corporation – manufacturer, supplier, and exporter – delivers robust and reliable protection for U-bend tubes operating in corrosive and high-temperature environments. With titanium stabilization and a custom-engineered fit, this shield ensures extended tube life, reduced wear, and optimized performance in industrial heating systems. For technical assistance, custom specifications, or quotations, please contact Ladhani Metal Corporation.

Send Message