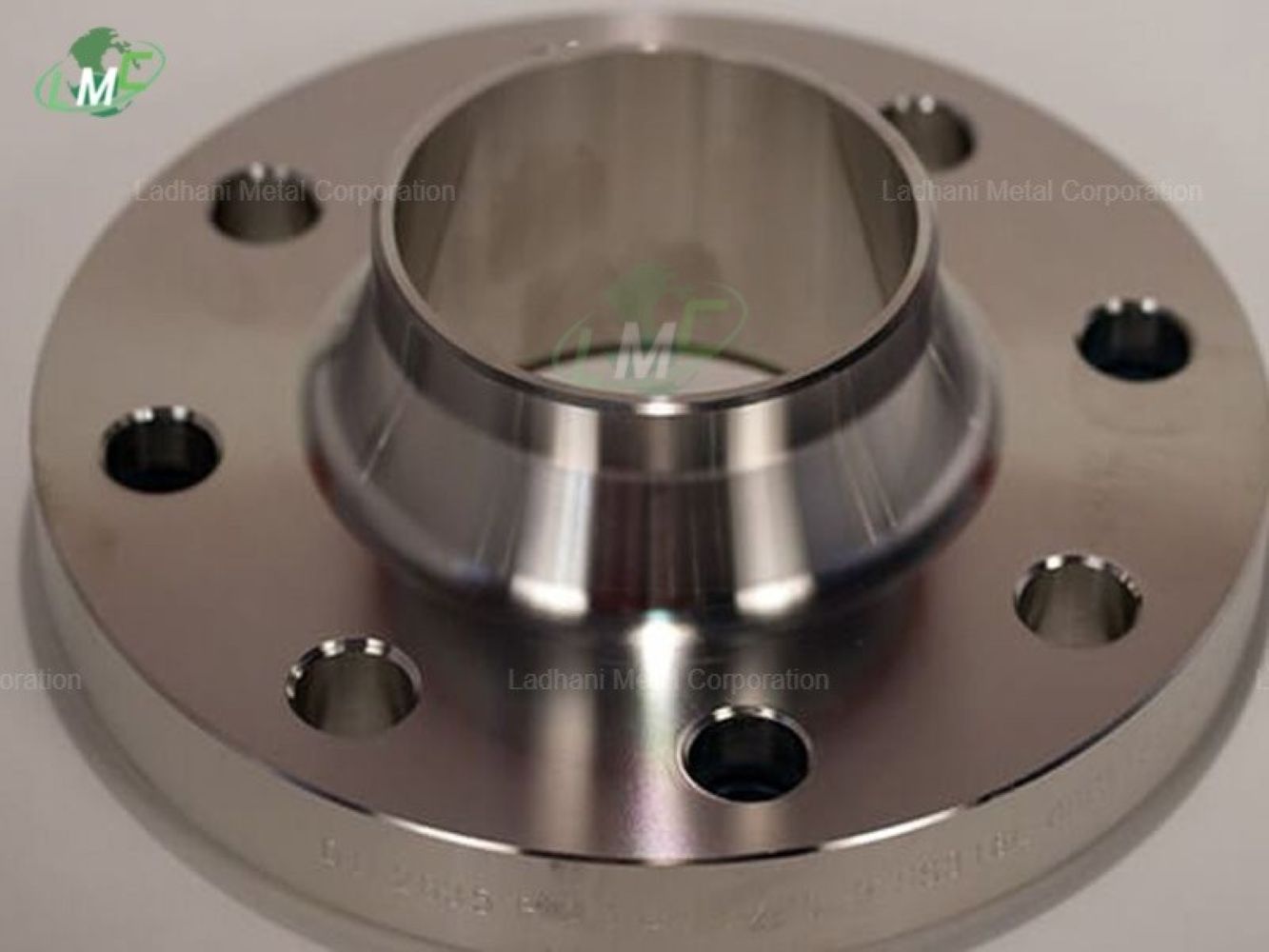

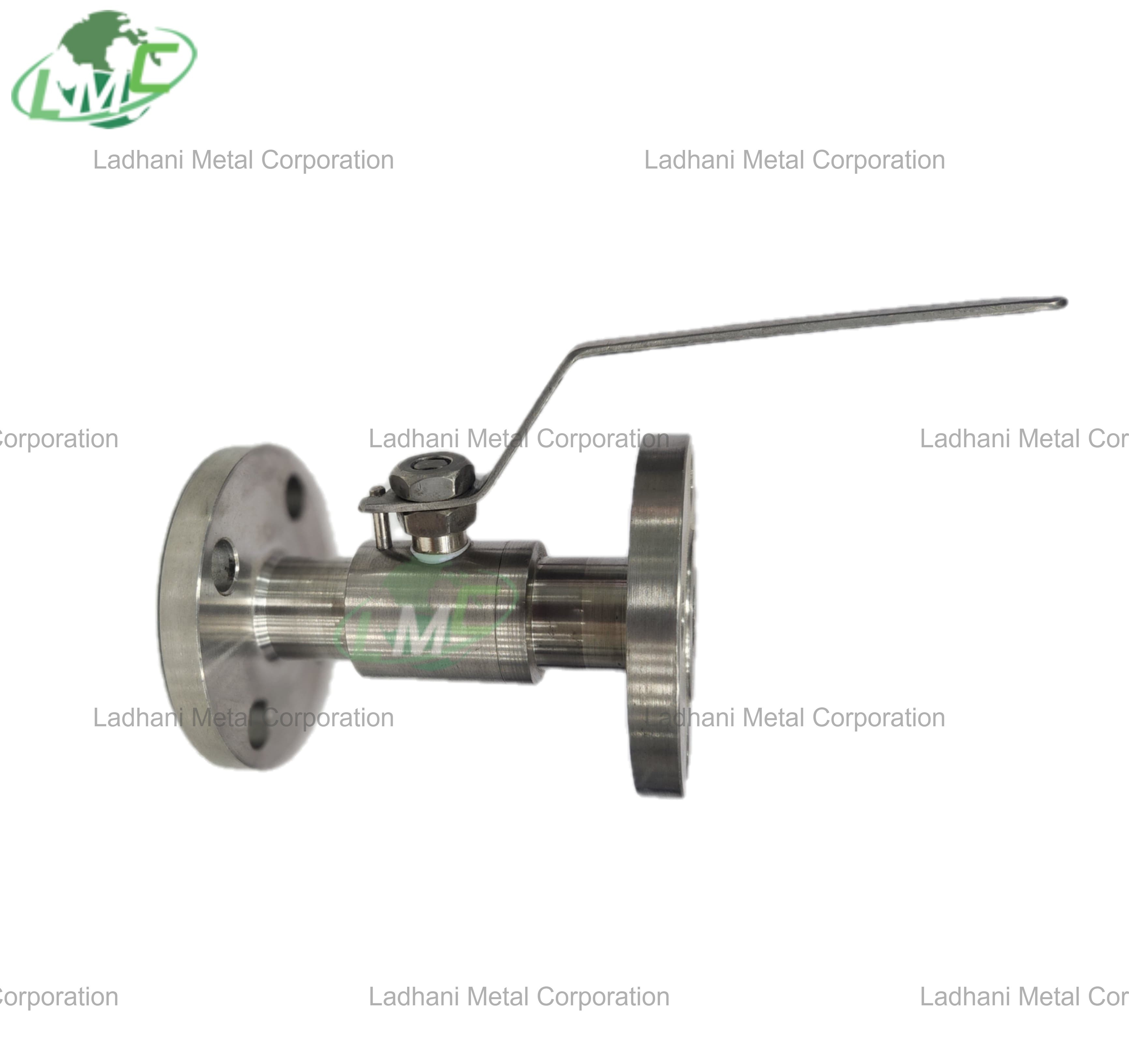

DIN 2627 Monel flanges PN 400 are high-performance blind flanges crafted for ultra-high-pressure systems where superior corrosion resistance, durability, and structural integrity are critical. Compliant with the DIN 2627 standard, these flanges are specifically designed to close off the ends of pipelines in extreme service environments, including highly corrosive marine atmospheres, acidic and alkaline chemical processes, and high-temperature applications. With a PN 400 rating (400 bar / 5800 psi), these flanges ensure leak-free operation under intense pressure and challenging conditions. Made from Monel alloys—primarily Monel 400 and Monel K500—these flanges are widely utilized in offshore oil rigs, naval applications, chemical processing, and power generation systems. Ladhani Metal Corporation is a global leader in manufacturing and exporting DIN-standard Monel flanges, ensuring compliance with international requirements for pressure containment, corrosion resistance, and metallurgical consistency. Pressure Rating: • PN 400 (400 bar / 5800 psi): Engineered for extremely high-pressure piping systems in critical and hazardous service environments where reliable sealing is essential. Flange Type: • Blind Flanges Solid, non-bored flanges used to seal piping systems or terminate flow paths. Ideal for pressure testing, system isolation, and future expansion. • Flat Face (FF) Flanges Designed with a flat sealing surface for use with full-face gaskets and flat mating components. Ensures uniform load distribution and optimal sealing performance. Monel Grades and Composition: Monel 400 (UNS N04400) • Nickel (Ni): ≥ 63% • Copper (Cu): 28 – 34% • Iron (Fe): ≤ 2.5% • Manganese (Mn): ≤ 2% • Silicon (Si): ≤ 0.5% • Carbon (C): ≤ 0.3% Applications: Outstanding resistance to seawater, hydrofluoric acid, alkalis, and other corrosive media. Widely used in marine equipment, chemical processing, and heat exchangers. Monel K500 (UNS N05500) • Nickel (Ni): ≥ 63% • Copper (Cu): 27 – 33% • Aluminum (Al): 2.3 – 3.15% • Titanium (Ti): 0.35 – 0.85% • Iron (Fe): ≤ 2% • Carbon (C): ≤ 0.25% Applications: Combines the corrosion resistance of Monel 400 with enhanced strength and hardness. Suitable for high-stress components like shafts, valve parts, and pump systems in corrosive environments. Applications of DIN 2627 Monel Flanges PN 400: • Offshore Oil and Gas Platforms Ideal for subsea systems exposed to high salinity, pressure, and corrosive gases such as hydrogen sulfide. • Marine and Shipbuilding Preferred in piping systems, ballast lines, and propulsion equipment exposed to seawater and biofouling agents. • Chemical and Petrochemical Plants Used in process systems handling caustic solutions, hydrofluoric acid, and strong alkalis at elevated pressures. • Heat Exchangers and Condensers Excellent thermal conductivity and corrosion resistance make Monel suitable for harsh thermal cycling conditions. • Nuclear and Power Generation Resilient in high-radiation and chemical-laden environments found in cooling systems and high-pressure steam lines. • Aerospace and Defense Used in fuel and hydraulic lines where strength and resistance to high-pressure corrosive media are critical. Key Features: • Manufactured according to DIN 2627 standards • Rated for PN 400 high-pressure operations • Blind flange design ensures reliable sealing and flow isolation • Flat face configuration for full-face gasket compatibility • Available in Monel 400 and Monel K500 grades • Exceptional resistance to corrosion by seawater, acids, and alkalis • High strength and durability in extreme service environments • Widely used in marine, chemical, nuclear, oil and gas, and aerospace industries • Custom configurations, sizes, and material options available on request Conclusion: DIN 2627 Monel Flanges PN 400 from Ladhani Metal Corporation are engineered for mission-critical applications where long-term durability, corrosion resistance, and high-pressure performance are mandatory. Whether you need protection against seawater, alkalis, or aggressive process chemicals, these flanges provide robust, leak-free service in the harshest operating environments. Contact Ladhani Metal Corporation for expert guidance, custom engineering, and dependable supply of Monel flange solutions tailored to your specific needs