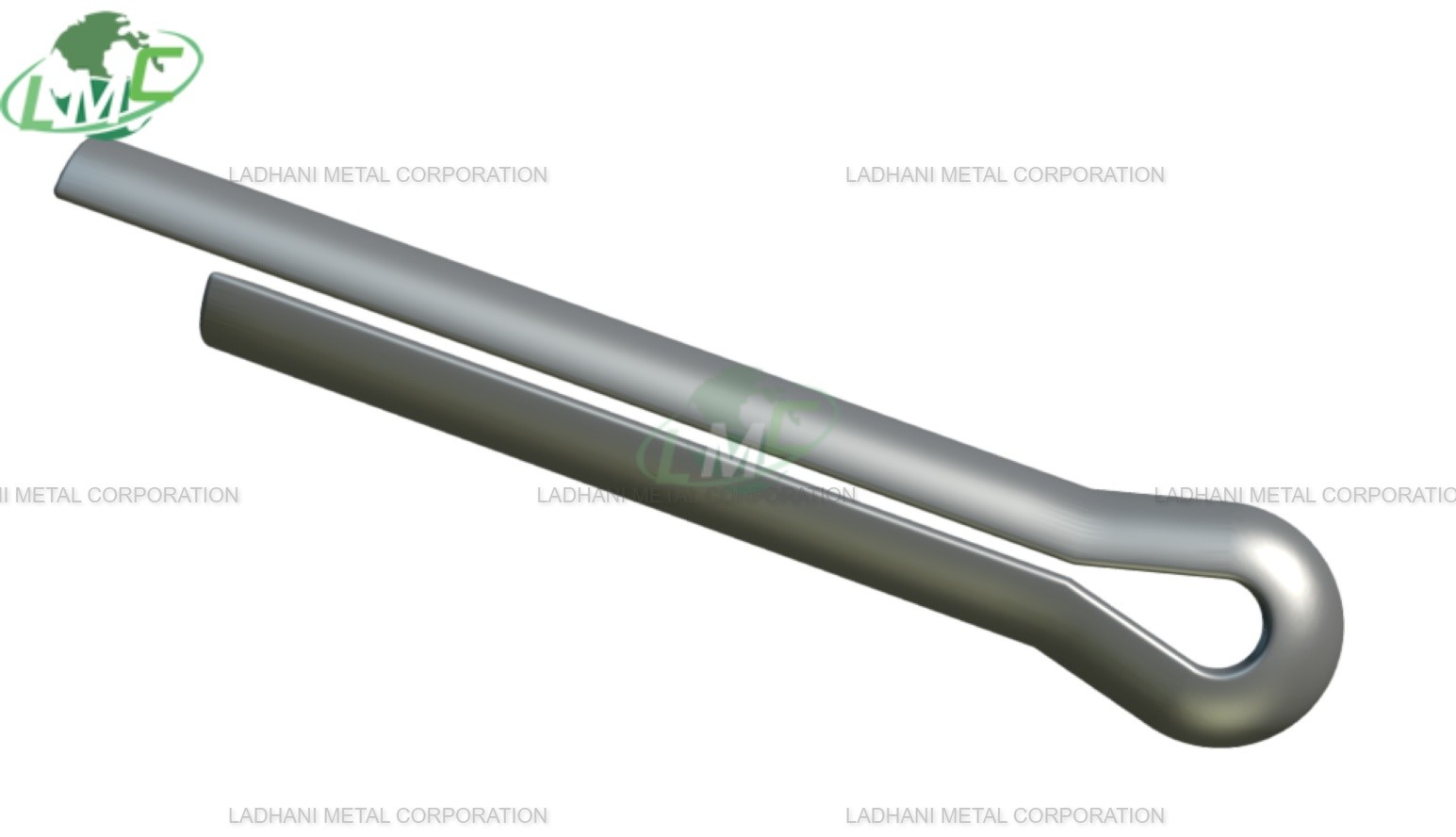

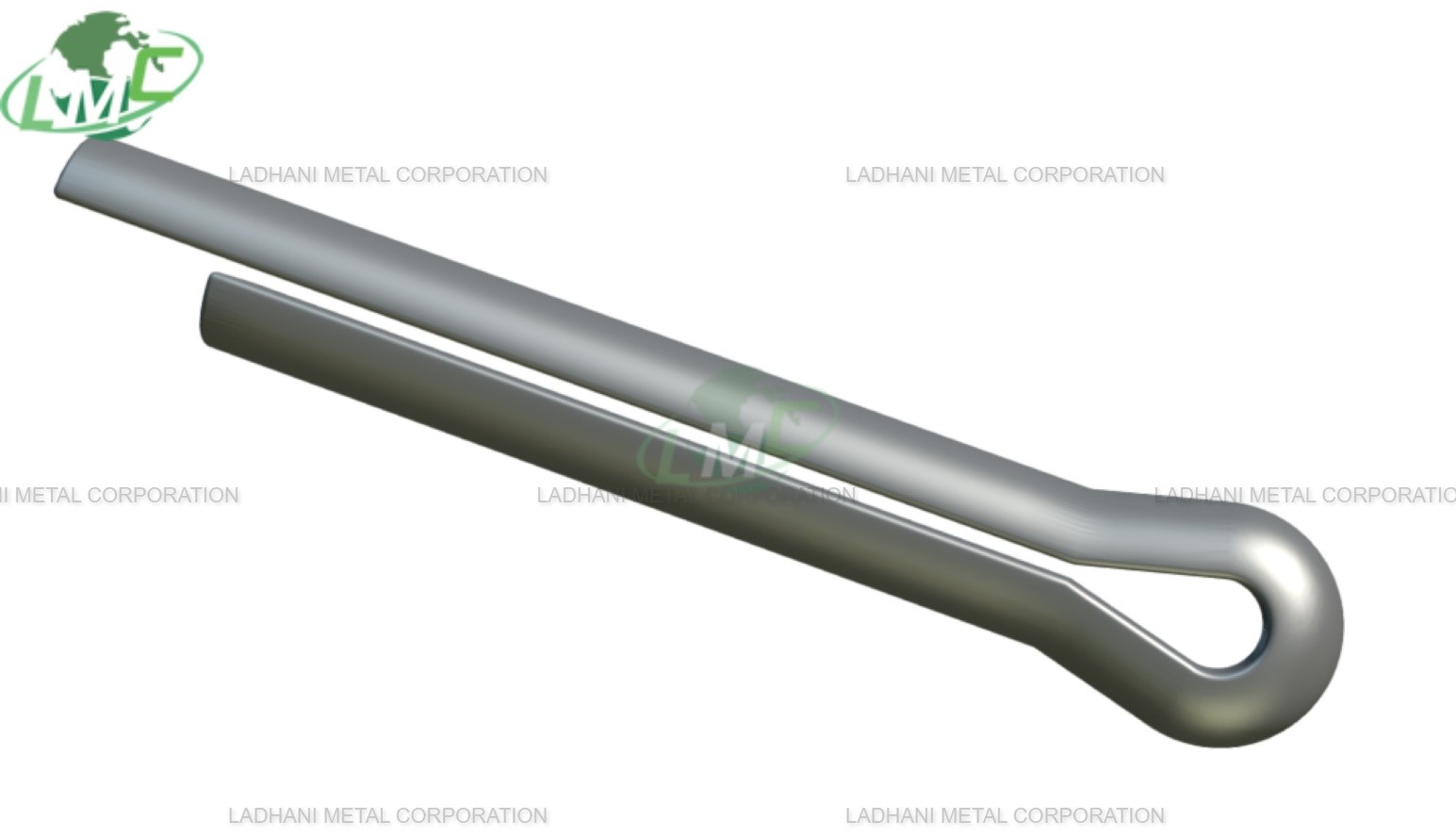

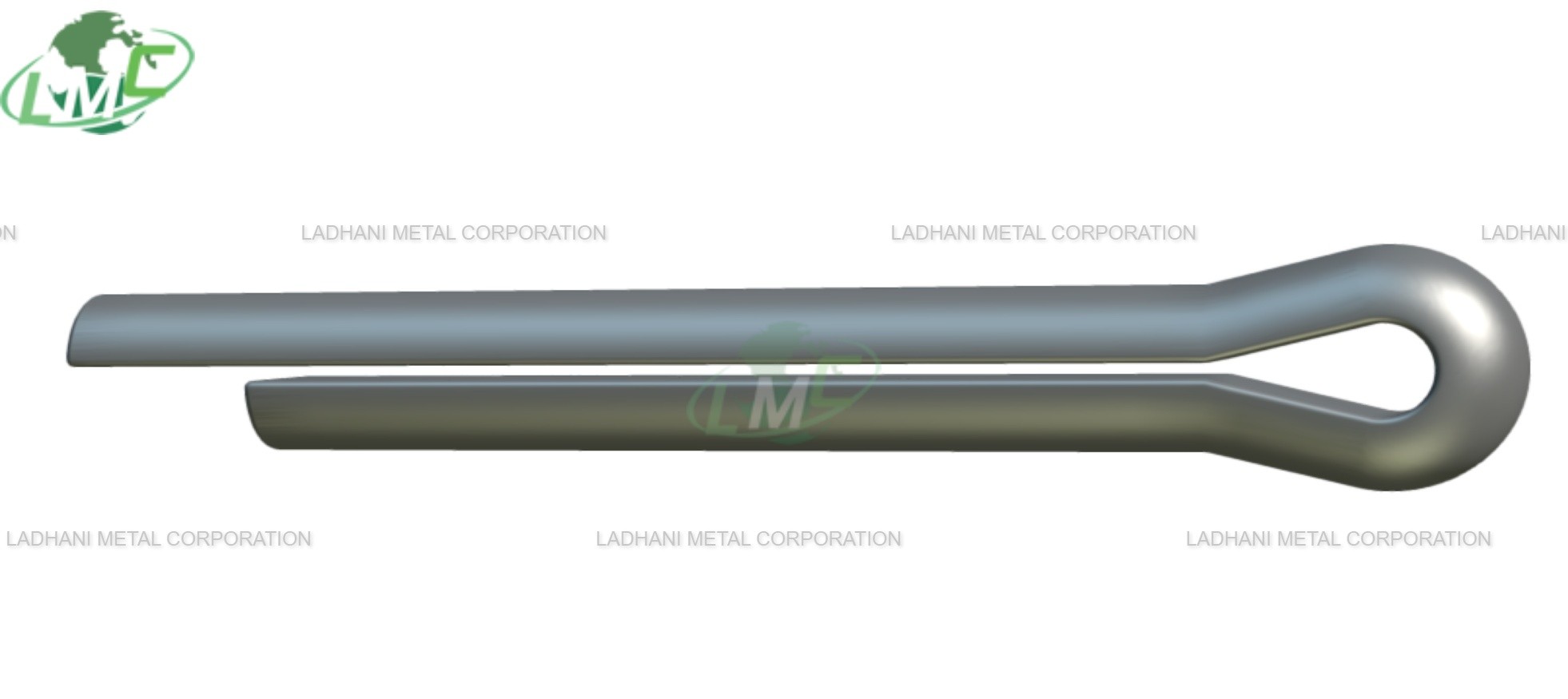

cotter pin/ split pin

DIN 94 Titanium Grade 1 Cotter Pin

Ladhani Metal Corporation, a trusted name in the manufacturing and supply of high-quality metal products in India, offers the DIN 94 Titanium Grade 1 Cotter Pin. Engineered to meet international standards, these Cotter pins are specifically designed for use in demanding applications where high strength, corrosion resistance, and durability are critical.

Key Features:

Material: Titanium Grade, known for its superior strength-to-weight ratio and excellent resistance to corrosion, particularly in harsh environments like marine, aerospace, and chemical industries.

Standards: Manufactured in compliance with DIN 94 specifications, ensuring consistency, reliability, and quality across every batch.

Corrosion Resistance: Ideal for use in environments where resistance to corrosion from chemicals, saltwater, and extreme temperatures is required.

High Strength: Titanium provides exceptional strength, making these Cotter pins suitable for high-stress applications.

Precision Engineering: Manufactured with exacting standards to ensure proper fitment and functionality in various mechanical assemblies.

Applications: Used extensively in aerospace, automotive, marine, and industrial machinery for securing parts and components in place, ensuring long-lasting performance.

We also manufacture in Titanium Grade 1, Titanium Grade 2, Titanium Grade 5, Titanium Grade 7 and Titanium Grade 9.

.

Our Domestic reach is unlimited and we supply to this following cities Ahmedabad, Amritsar, Aurangabad, Bangalore, Bhopal, Chandigarh, Chennai, Coimbatore, Dhanbad, Faridabad, Ghaziabad, Guwahati, Gwalior, Howrah, Hyderabad, Indore, Jabalpur, Jaipur, Jodhpur, Kanpur, Kolkata, Kota, Lucknow, Ludhiana, Madurai, Meerut, Mumbai, Nagpur, Nashik, Navi Mumbai, New Delhi, Patna, Pune, Raipur, Rajkot, Ranchi, Solapur, Srinagar, Surat, Thane, Vadodara, Varanasi, Vijayawada, Visakhapatnam, Hubballi, Tiruchirappalli, Bareilly, Moradabad, Mysore, Gurgaon, Aligarh, Jalandhar, Bhubaneswar

We export to following Countries:

Russia, Canada, United States, China, Brazil, Australia, Argentina, Kazakhstan, Algeria, Denmark, Saudi Arabia, Mexico, Indonesia, Iran, Mongolia, Peru, South Africa, Colombia, Ethiopia, Bolivia, Egypt, Venezuela, Turkey, Chile, Myanmar, France, Ukraine, Madagascar, Botswana, Kenya, Thailand, Spain, Sweden, Uzbekistan, Morocco, Paraguay, Zimbabwe, Norway, Japan, Germany, Republic of the Congo, Finland, Vietnam, Malaysia, Poland, Oman, Italy, Philippines, Ecuador, New Zealand, United Kingdom, Guinea, Uganda, Nepal, Bangladesh

Send Message