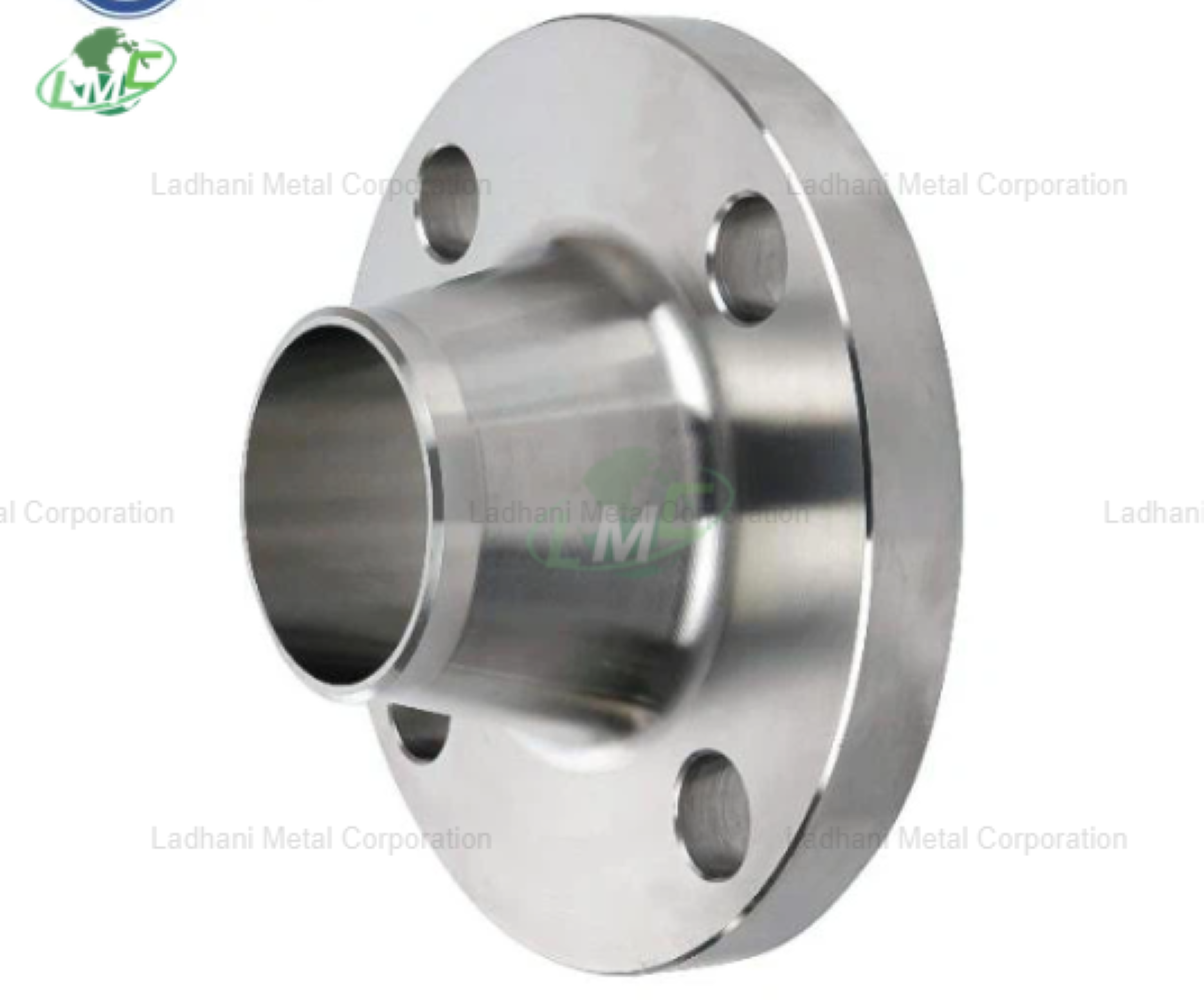

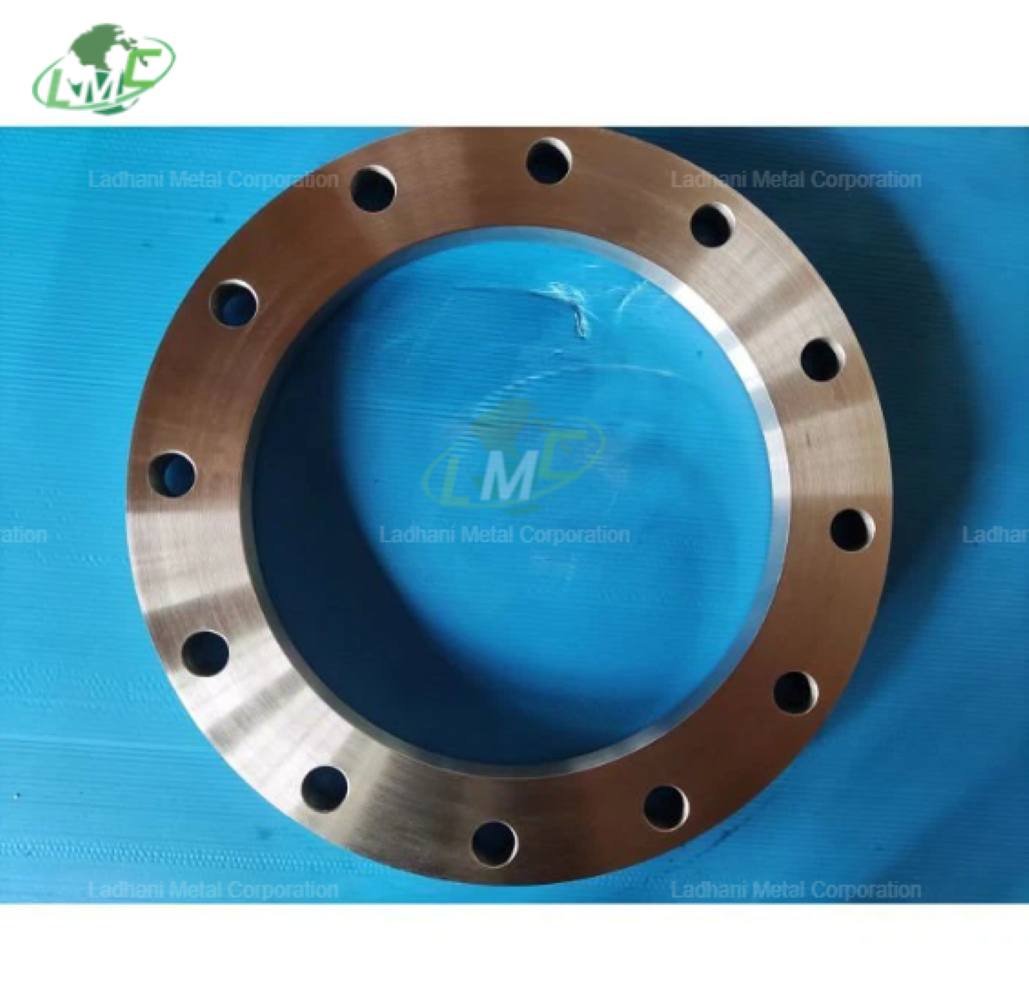

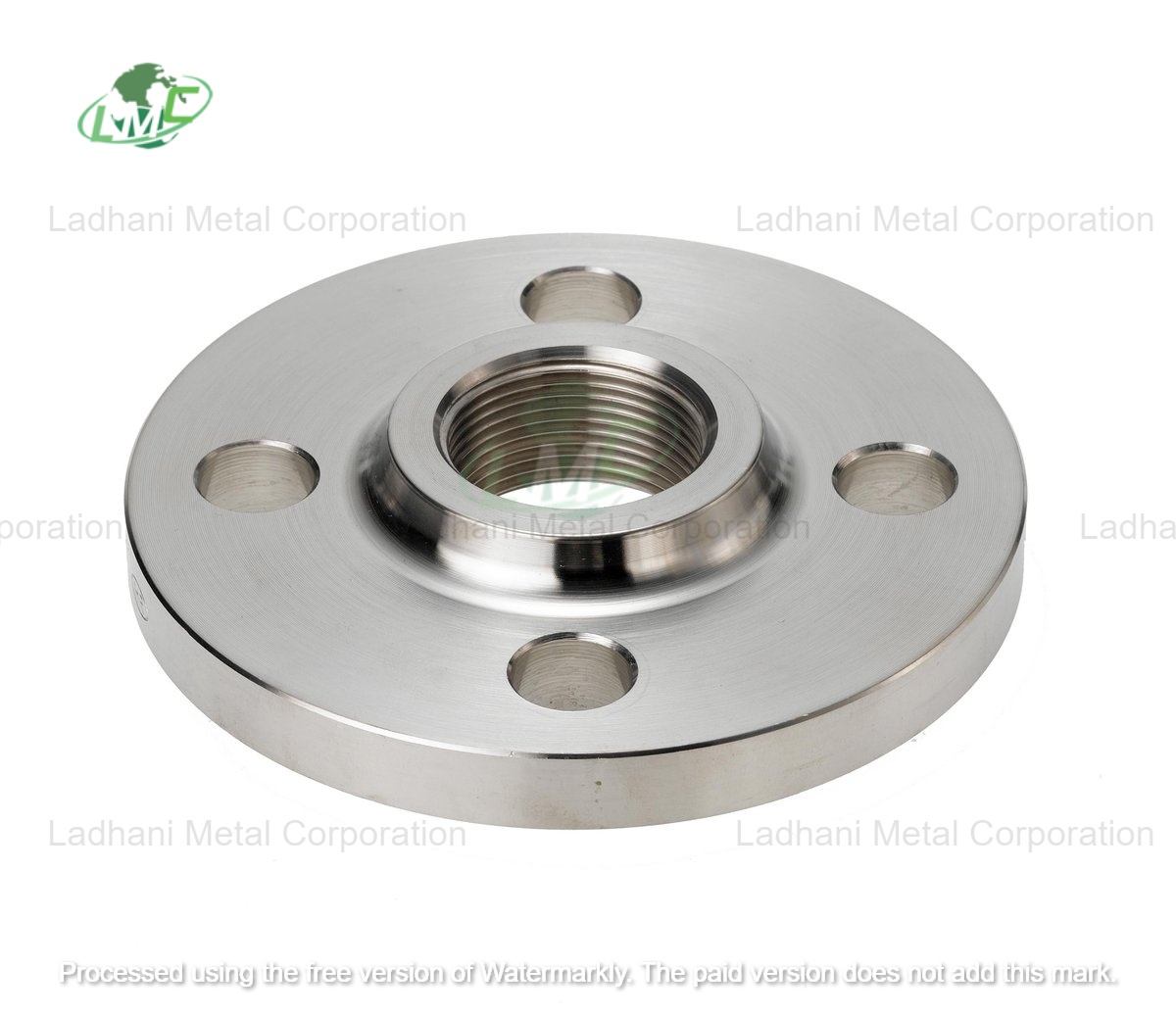

DIN 2630 carbon steel flanges PN 2.5 are precision-engineered weld neck flanges designed in accordance with the DIN 2630 standard, suitable for low-pressure applications up to 2.5 bar (36.25 psi). Manufactured from high-quality carbon steel grades such as ASTM A105 and A350 LF2, these flanges offer reliable mechanical strength and excellent weldability. Carbon steel flanges are ideal for general-purpose piping systems where toughness, cost-effectiveness, and structural integrity are required in low-pressure environments. Ladhani Metal Corporation is a trusted global manufacturer and supplier of carbon steel flanges, known for delivering quality components built to meet international standards. Our DIN 2630 PN 2.5 carbon steel weld neck flanges are widely used in industries such as oil and gas, water treatment, power generation, and general manufacturing. Every flange is manufactured under stringent quality control to ensure performance, durability, and compliance with customer requirements. Pressure Rating: • PN 2.5 (2.5 bar / 36.25 psi): Designed for low-pressure systems requiring durable, cost-effective materials with high mechanical strength. Flange Type: • Weld Neck Flanges Equipped with a long tapered hub to ensure smooth fluid flow and reduce stress concentration, these flanges are suited for critical applications involving pressure and temperature changes. • Flat Face (FF) Flanges Flat face flanges provide uniform gasket compression, especially when used with cast components or soft gasket materials in low-pressure setups. Carbon Steel Grades and Chemical Composition: ASTM A105 (Forged Carbon Steel) • Carbon (C): ≤ 0.35% • Manganese (Mn): 0.60 – 1.05% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.040% • Silicon (Si): 0.10 – 0.35% Applications: Commonly used in ambient- and high-temperature service in pressure systems. Ideal for general-purpose industrial piping, valve connections, and flanged joints. ASTM A350 LF2 (Low-Temperature Carbon Steel) • Carbon (C): ≤ 0.30% • Manganese (Mn): 0.60 – 1.35% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.040% • Silicon (Si): 0.15 – 0.30% Applications: Designed for low-temperature services where enhanced notch toughness is essential, such as cryogenic and refrigerated systems. Applications of DIN 2630 Carbon Steel Flanges PN 2.5: • Oil and Gas Industry Used in upstream and downstream piping for fluid transport under low-pressure conditions. • Water Treatment Plants Ideal for piping systems handling potable water, wastewater, and industrial effluents. • Power Generation Applied in cooling systems, boilers, and auxiliary piping in thermal and hydroelectric power plants. • General Industrial Use Suitable for manufacturing facilities, mechanical piping, and structural connections. Key Features: • Manufactured as per DIN 2630 standards • PN 2.5 pressure class for low-pressure piping systems • Weld neck design improves mechanical stability and flow characteristics • Flat face option enables consistent sealing with softer gasket materials • High strength, excellent machinability, and cost-efficiency • Available in standard and customized sizes, face types, and surface finishes Conclusion: DIN 2630 Carbon Steel Flanges PN 2.5 from Ladhani Metal Corporation provide a practical and durable solution for low-pressure piping systems across various industries. With strong mechanical properties, reliable performance, and economical pricing, these flanges are ideal for applications requiring consistent quality and weldability. For technical support, custom solutions, or pricing, contact Ladhani Metal Corporation.

Send Message