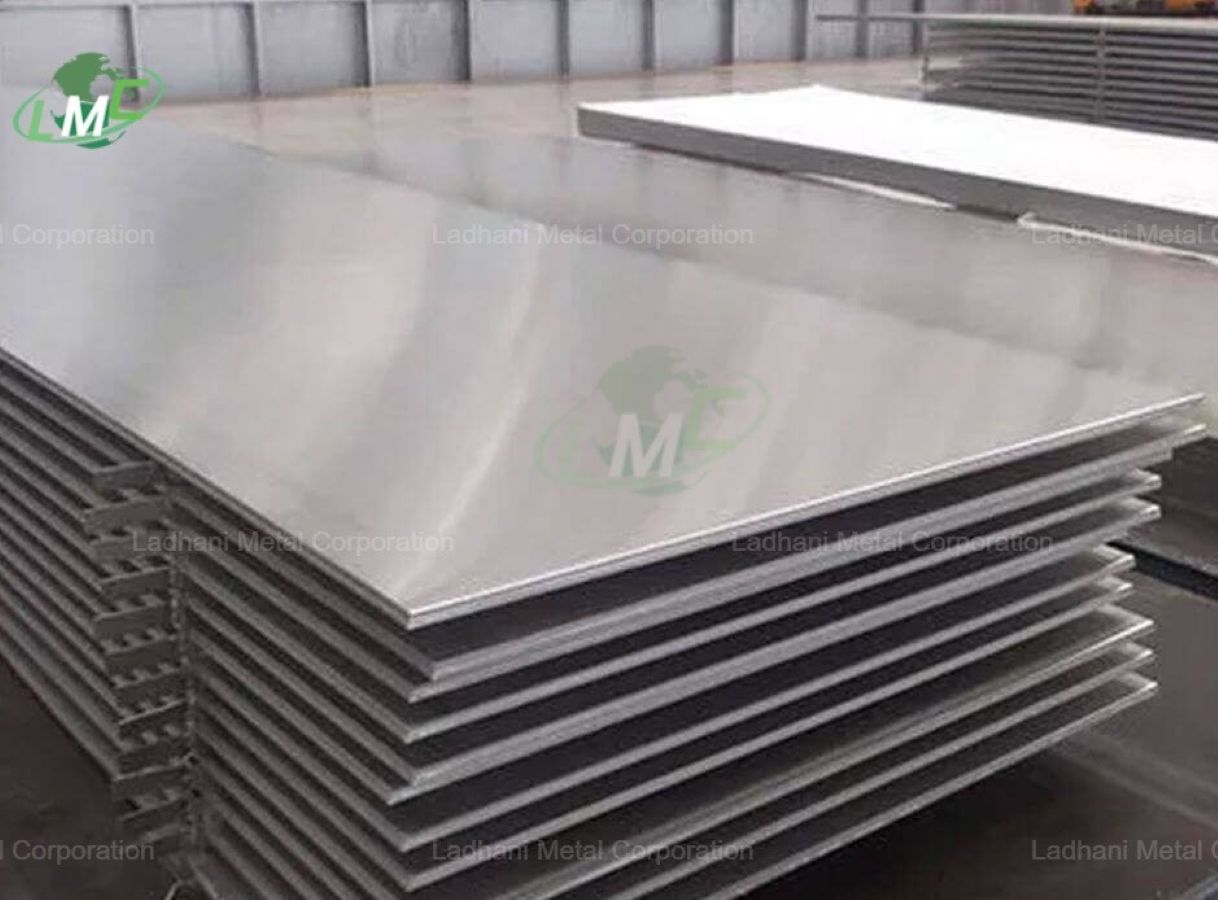

EN 10088 SS X6CrNiTi12 is an austenitic stainless steel grade containing approximately 12% chromium, 6% nickel, and stabilized with titanium. This grade is designed to provide excellent resistance to oxidation, scaling, and corrosion in moderately aggressive environments. Titanium stabilization prevents intergranular corrosion by binding carbon, ensuring superior weldability and durability even in high-temperature applications. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of EN 10088 SS X6CrNiTi12 Plate, Sheet, Coil, and Strip. Our products are available in various thicknesses, widths, and finishes to meet diverse industrial requirements. They are widely used in sectors such as chemical, petrochemical, heat treatment, food processing, and general engineering where corrosion resistance and high-temperature stability are critical. Forms Available: plate, sheet, coil, strip Chemical Composition (%): • Carbon (C): ≤ 0.08 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 2.00 • Phosphorus (P): ≤ 0.045 • Sulphur (S): ≤ 0.015 • Chromium (Cr): 11.0 – 13.0 • Nickel (Ni): 5.5 – 7.5 • Titanium (Ti): ≥ 5 × C and ≤ 0.70 Mechanical Properties: • Tensile Strength: 500 – 700 MPa • Yield Strength (0.2% Proof): ≥ 205 MPa • Elongation: ≥ 40% • Hardness (HB): ≤ 200 Key Features: • Excellent resistance to corrosion and oxidation • Titanium stabilization enhances intergranular corrosion resistance • Good weldability and formability • Reliable performance under elevated temperatures Material Characteristics: EN 10088 SS X6CrNiTi12 Plate offers high dimensional stability and maintains strength at elevated temperatures. Its austenitic structure provides excellent toughness and ductility, making it suitable for forming, bending, and welding operations. The material also exhibits outstanding resistance to scaling and corrosion in oxidizing environments, ensuring a long service life in both industrial and structural applications. Applications: • Chemical and petrochemical equipment • Heat exchangers and furnace components • Food processing and pharmaceutical equipment • Industrial tanks, ducts, and architectural structures Conclusion: Ladhani Metal Corporation supplies high-quality EN 10088 SS X6CrNiTi12 Plate, Sheet, Coil, and Strip with precise dimensions and superior surface finish. For material specifications, technical details, or customized requirements, please contact Ladhani Metal Corporation – your trusted partner for stainless steel solutions. #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar #EN10088 #EN10088StainlessSteel #En10088SheetPlateCoilStrip #SSSheet #SSPlate #SSCoil #SSStrip #ColdRolledSteel #HotRolledSteel #CustomFabrication #CorrosionResistantSteel #DurableSteel #PrecisionEngineered #EN10088SSManufacturer #EN10088SSSupplier #EN10088SSExporter #ISOApproved #InternationalGradeSteel #HighPerformanceSteel #IndustrialSheet #IndustrialPlate #IndustrialCoil #IndustrialStrip #StainlessSteelSupplier #StainlessSteelManufacturer #StainlessSteelExporter #MetalFabrication #IndustrialApplications #ConstructionMaterials #EngineeringMaterials #OEMApplications #LadhaniMetals #MetalSupplier #MetalExporter #SteelIndustry #MarineSteelApplications #AutomotiveSteelApplications #ChemicalProcessingSteel #FoodProcessingSteel #PharmaGradeSteel #PowerGenerationSteel #HeatExchangerSteel #WaterTreatmentSteel #ArchitecturalSteel #IndustrialEquipmentSteel #CustomMetalSolutions #GlobalExporter #IndianManufacturer #TechnicalSpecifications #MaterialStandards #SteelFabricator #IndustrialSupplier #StainlessSteelIndia #StainlessSteelExporters #IndustrialMetals #MetalSheets #MetalPlates #MetalCoils #MetalStrips #SheetMetalProcessing #SteelFabrication #EngineeringProjects #OEMMetalSolutions #HighQualitySteel #LongLifeMaterial #FabricationMaterials #IndustrialSteel #StainlessSteelProducts