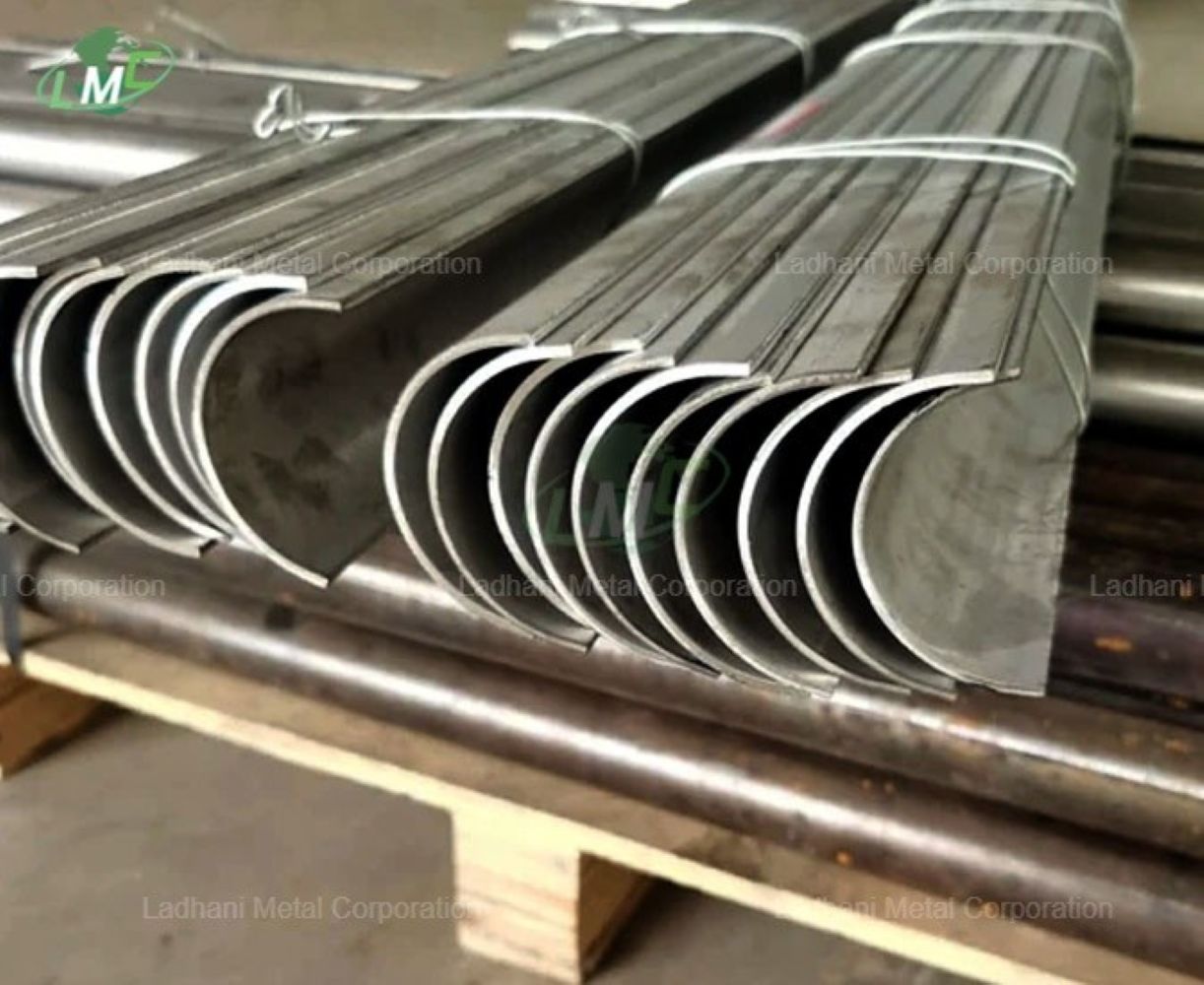

Half Round Tube Shield Half Round Tube Shields from Ladhani Metal Corporation are durable, precisely fabricated components used to protect boiler tubes from erosion, scaling, and corrosion caused by flue gas flow and particulate impact. Their half-round, semi-cylindrical structure is designed to conform closely to tube surfaces, especially in areas subjected to repeated thermal cycling or mechanical wear. These shields are extensively applied in boilers, heat exchangers, and waste heat recovery systems. 1Cr25Ni20Si2 Half Round Tube Shield for LTSH Tube The 1Cr25Ni20Si2 Half Round Tube Shield is manufactured from a high-performance chromium-nickel-silicon alloy designed for elevated-temperature service. With approximately 25% chromium, 20% nickel, and added silicon content, this alloy exhibits superior resistance to oxidation, thermal fatigue, and carburization. Its mechanical stability under high-temperature operation makes it a preferred material for protective applications in Low Temperature Superheater (LTSH) zones. The Low Temperature Superheater (LTSH) is a section in a boiler where saturated steam from the steam drum is superheated to a moderately higher temperature before entering the high-temperature superheater stages. Positioned in areas with relatively lower flue gas temperatures, the LTSH helps improve thermal efficiency and reduces moisture content in steam. Due to constant exposure to abrasive flue gases and ash, LTSH tubes are prone to wear and require protective shielding, such as half round tube shields, to extend service life. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of 1Cr25Ni20Si2 Half Round Tube Shields, offering high-performance shielding solutions tailored for harsh, heat-intensive industrial environments. Chemical Composition of 1Cr25Ni20Si2 – Chromium-Nickel-Silicon Heat-Resistant Steel • Carbon (C): ≤ 0.10% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): 1.5 – 2.5% • Chromium (Cr): 24.0 – 27.0% • Nickel (Ni): 19.0 – 22.0% • Iron (Fe): Balance Applications: Suitable for high-temperature steam systems, where resistance to flue gas corrosion, thermal oxidation, and mechanical fatigue is essential. Uses • Protects LTSH tubes in thermal power plants from scaling and soot-induced wear • Shields heat exchanger tubes from low-temperature corrosive gases and ash deposition • Used in boilers and HRSGs exposed to fluctuating temperature and combustion by-products • Suitable for high-wear areas in biomass boilers and incineration systems • Enhances operational life of reheater and superheater coil sections Features • High thermal stability – Withstands temperature fluctuations without structural deformation • Excellent oxidation and carburization resistance – Ideal for extended high-temperature exposure • Custom fit – Designed according to specific tube radii and coil geometries for accurate alignment • Reduced maintenance – Shields tubes from damage, minimizing downtime and repair costs • Versatile installation – Compatible with weld-on, clamp-on, and banding installation techniques • Long service life – Resistant to scaling and degradation in heat-intensive environments Applications • power generation boilers – Provides long-term protection for LTSH coils in flue gas zones • WHRBs and HRSGs – Used in low-temperature convection sections to counteract erosive gas flow • chemical and refining industries – Prevents corrosion in heat exchangers handling acidic media • marine steam systems – Protects low-temperature sections exposed to salt-laden air and gases • waste-to-energy plants – Shields boiler tubing from high-volume particulate streams Conclusion The 1Cr25Ni20Si2 Half Round Tube Shield for LTSH Tube by Ladhani Metal Corporation – manufacturer, supplier, and exporter – is a high-performance component designed for superior protection of boiler tubes in corrosive and thermally aggressive environments. It ensures durability, thermal resistance, and long-term reliability in LTSH and similar service applications. For specifications, custom fabrication, or bulk orders, contact Ladhani Metal Corporation.

Send Message