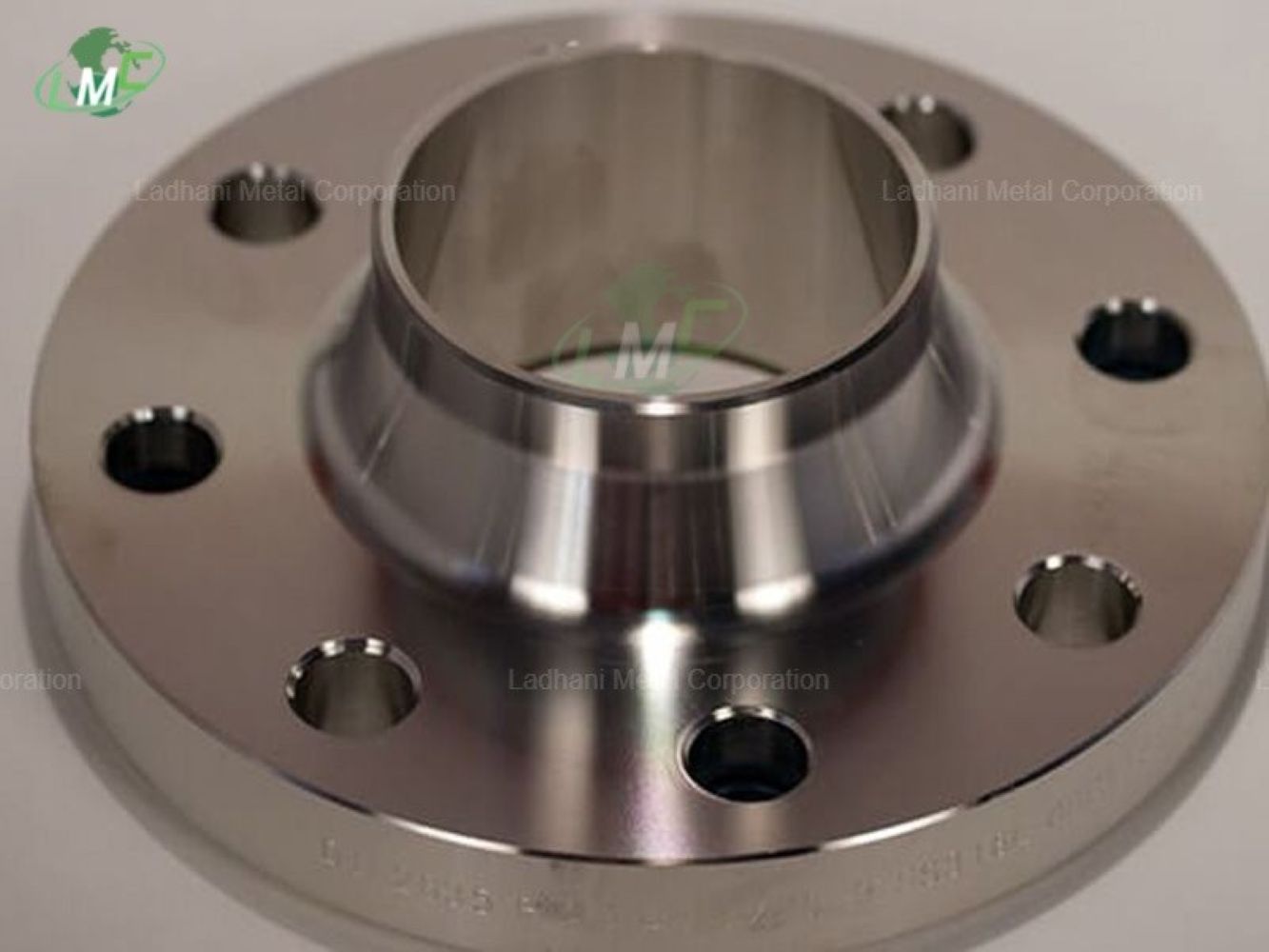

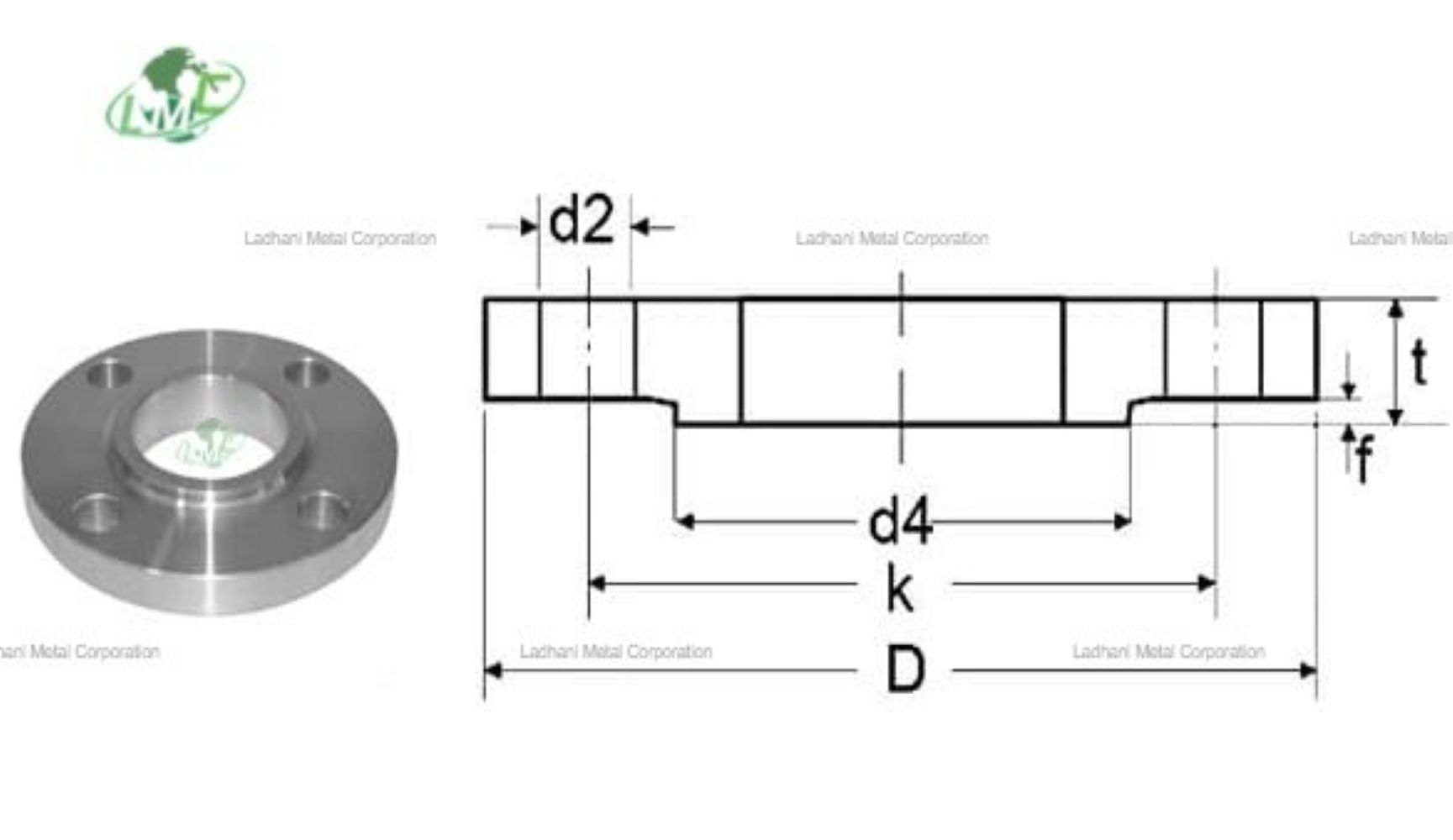

DIN 2627 Carbon Steel flanges PN 400 are high-strength blind flanges designed for use in high-pressure applications across a wide range of industrial systems. Manufactured in accordance with the DIN 2627 standard, these flanges are primarily used to isolate piping systems by sealing off the end of a pipeline or vessel opening. The PN 400 pressure rating (400 bar / 5800 psi) ensures reliable performance under intense pressure and mechanical stress. Carbon steel flanges offer excellent tensile strength, impact resistance, and structural integrity, making them a cost-effective solution for systems where corrosion resistance is not the primary concern. Typically used in applications involving water, steam, oil, and gas, DIN 2627 carbon steel blind flanges are well-suited for power plants, refineries, petrochemical facilities, and general industrial systems. Ladhani Metal Corporation is a trusted global manufacturer and exporter of carbon steel flanges, producing components that meet rigorous international standards for material quality, dimensional accuracy, and pressure containment. Pressure Rating: • PN 400 (400 bar / 5800 psi): Suitable for extremely high-pressure systems in industrial pipelines and mechanical installations. Flange Type: • Blind Flanges Solid, non-bored flanges used to terminate flow or provide system isolation. Commonly used for pressure testing, maintenance access, and future expansion. • Flat Face (FF) Flanges Flat sealing surfaces designed for use with full-face gaskets and flat-faced mating flanges. Promotes even bolt loading and effective sealing under high-pressure conditions. Carbon Steel Grades and Composition: ASTM A105 (Forged Carbon Steel) • Carbon (C): ≤ 0.35% • Manganese (Mn): 0.60 – 1.05% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.040% • Silicon (Si): 0.10 – 0.35% Applications: Commonly used for high-temperature and high-pressure systems. Ideal for oil and gas, steam, and hydraulic systems. ASTM A350 LF2 (Low-Temperature Carbon Steel) • Carbon (C): ≤ 0.30% • Manganese (Mn): 0.60 – 1.35% • Silicon (Si): 0.15 – 0.30% • Nickel (Ni): ≤ 1.0% Applications: Suitable for sub-zero temperature services such as cryogenic systems, LNG processing, and cold-weather pipelines. Applications of DIN 2627 Carbon Steel Flanges PN 400: • Oil and Gas Transmission Lines Used in pipeline systems and refineries handling hydrocarbons under high pressure. • Steam and Power Generation Plants Ideal for high-pressure steam lines, condensate systems, and boiler feedwater applications. • Petrochemical and Chemical Industries Suitable for handling neutral and non-aggressive chemical fluids and process gases. • Water Treatment and Pumping Stations Used in high-pressure water systems, including pumping stations, pressure regulators, and testing units. • Heating, Ventilation, and Air Conditioning (HVAC) Employed in high-pressure chilled water and steam systems for industrial facilities. • General Manufacturing and Engineering Systems Reliable for structural piping systems in factories and mechanical installations. Key Features: • Compliant with DIN 2627 specifications • PN 400 pressure rating for ultra-high-pressure systems • Blind flange design allows for system isolation and pressure containment • Flat face design compatible with full-face gaskets and flat mating surfaces • Manufactured from forged carbon steels like ASTM A105 and A350 LF2 • Excellent strength, ductility, and impact resistance • Economical and durable for non-corrosive environments • Widely used across oil and gas, power, chemical, and water treatment sectors • Custom sizes, pressure classes, surface coatings, and face types available upon request Conclusion: DIN 2627 Carbon Steel Flanges PN 400 from Ladhani Metal Corporation are engineered for high-performance applications requiring strength, pressure retention, and reliability in demanding industrial environments. Whether used in power plants, oil pipelines, or steam systems, these flanges provide durable and cost-effective sealing for critical operations. Contact Ladhani Metal Corporation for product specifications, technical support, or custom solutions tailored to your piping system requirements.

Send Message