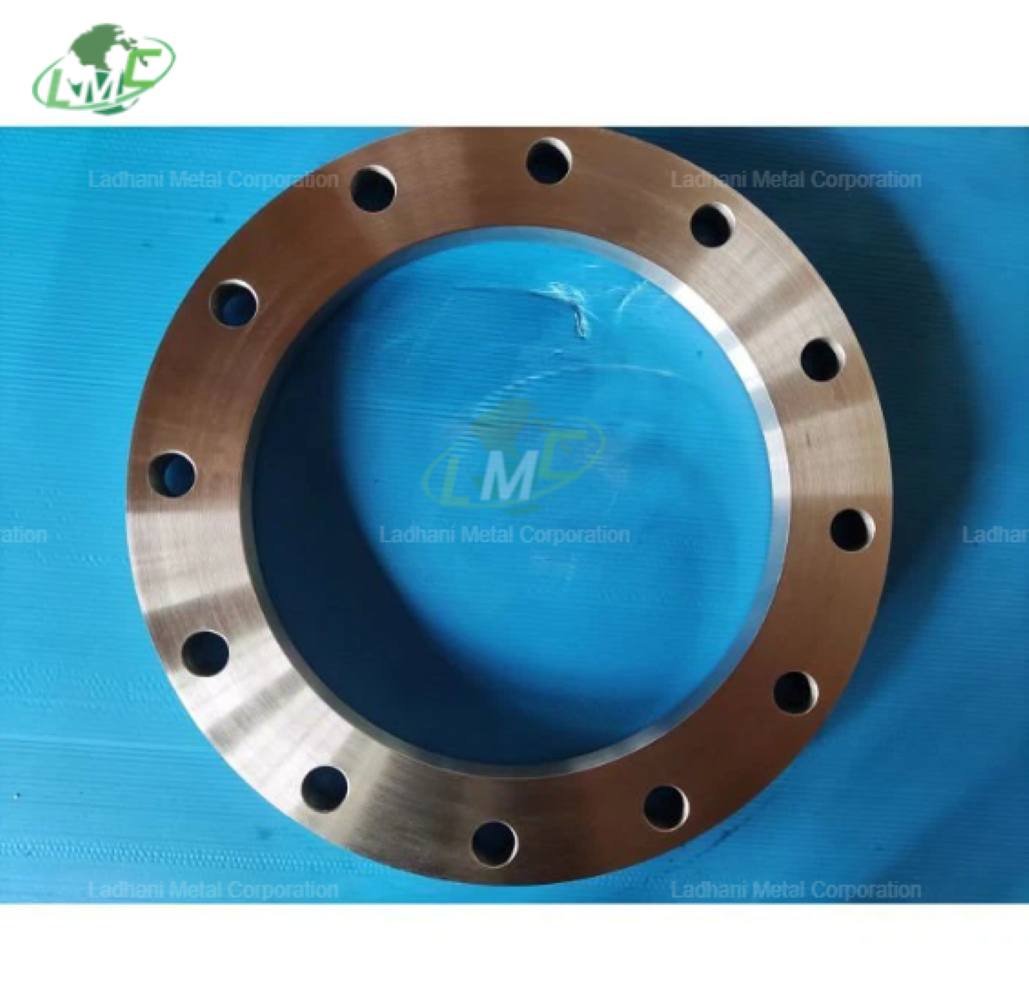

DIN 2633 carbon steel flanges PN 16 are reliable weld neck flanges manufactured in compliance with the DIN 2633 standard. Designed for use in medium-pressure piping systems with a pressure rating of up to 16 bar (232 psi), these flanges are fabricated from high-quality carbon steel, providing dependable mechanical strength and ease of fabrication. They are widely utilized in a range of general industrial and utility applications where corrosion resistance demands are moderate. Ladhani Metal Corporation is a globally trusted manufacturer and supplier of carbon steel flanges, recognized for high-precision production, rigorous quality assurance, and strict adherence to international material and dimensional standards. Every flange is tested to ensure consistent performance, mechanical integrity, and compatibility with a variety of piping systems. Pressure Rating: • PN 16 (16 bar / 232 psi): Suitable for medium-pressure systems requiring strong, cost-effective, and durable connections. Flange Type: • Weld Neck Flanges Featuring an extended tapered hub, weld neck flanges help evenly distribute mechanical stress and ensure secure, vibration-resistant joints, particularly effective in systems subject to bending or thermal expansion. • Flat Face (FF) Flanges Ideal for use with soft gaskets or cast iron components, flat face flanges ensure even gasket compression, reducing the risk of flange warping or over-tightening. Carbon Steel Grades and General Composition: Typical Carbon Steel Grade: ASTM A105 (for forged carbon steel flanges) • Carbon (C): 0.35% max • Manganese (Mn): 0.60 – 1.05% • Phosphorus (P): 0.035% max • Sulfur (S): 0.040% max • Silicon (Si): 0.10 – 0.35% • Iron (Fe): Balance Applications: Carbon steel flanges to DIN 2633 PN 16 are widely applied in environments where corrosion resistance is not the primary concern but where mechanical strength, weldability, and cost-efficiency are essential. Applications of DIN 2633 Carbon Steel Flanges PN 16: • Power Plants Used in steam, water, and air systems for medium-pressure operations. • Water Treatment and Distribution Well-suited for water mains, treatment facilities, and irrigation networks where strength and reliability are critical. • Petrochemical and Refining Industries Employed in non-corrosive process piping, utility lines, and support systems. • HVAC and Fire Protection Systems Ideal for chilled water, fire suppression, and compressed air applications. • General Industrial Manufacturing Used in structural piping systems and mechanical infrastructure with stable temperature and pressure conditions. Key Features: • Manufactured to DIN 2633 specifications • PN 16 pressure rating for medium-duty service • Weld neck configuration provides robust, leak-resistant connections • Cost-effective and easy to fabricate and install • Excellent machinability and weldability • Available in various sizes and configurations • Coating and corrosion protection options available upon request Conclusion: DIN 2633 carbon steel flanges PN 16 from Ladhani Metal Corporation are engineered for dependable performance in standard industrial environments. With proven strength, versatility, and affordability, these flanges are a reliable choice for water, steam, gas, and general utility applications. For detailed technical specifications, custom options, or pricing inquiries, contact Ladhani Metal Corporation today.