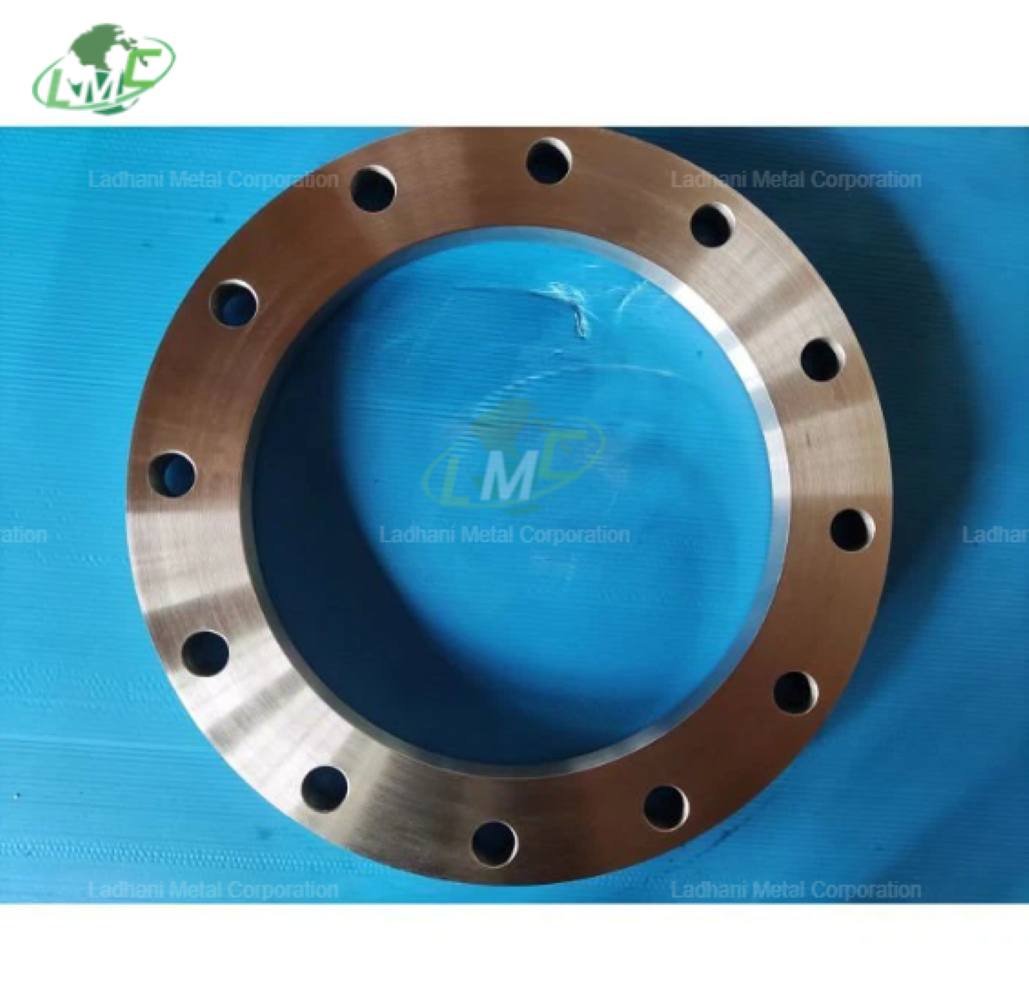

DIN 2573 Stainless Steel Flanges PN 6 are precision-manufactured flat flanges made from high-grade stainless steel, designed for low-pressure applications across a broad range of industrial sectors. Compliant with DIN 2573 standards, these flanges provide excellent corrosion resistance, mechanical reliability, and compatibility with standard piping systems. They are commonly used in non-critical, low-pressure environments in industries such as water treatment, HVAC, food processing, and general utility piping systems. Ladhani Metal Corporation is a reputable manufacturer and exporter of stainless steel flanges, offering components that adhere to international quality benchmarks. The flat flange design simplifies assembly and disassembly, making these flanges a practical choice for systems requiring easy maintenance and reliable sealing at lower pressure ranges. Pressure Rating: • PN 6 (6 bar / 87 psi): Engineered for low-pressure systems where moderate sealing performance and corrosion resistance are essential. Flange Types: • Plate Flanges Used in low-pressure piping systems for simple bolted connections with gaskets. • Flat Face (FF) Flanges Ideal for use with cast iron equipment or non-metallic gaskets to ensure uniform surface contact. • Slip-On Flanges Designed for ease of installation by sliding over the pipe and welding both sides for moderate sealing. • Custom-Machined Flanges Available in specific dimensions and stainless steel grades as per customer specifications and operational requirements. Stainless Steel Grades and Composition: 1. 304 (Austenitic Stainless Steel) Composition: • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 18.0 – 20.0% • Nickel (Ni): 8.0 – 11.0% Applications: Used in water supply lines, food-grade piping, and low-pressure process lines due to its hygienic properties and corrosion resistance. 2. 316 (Molybdenum-Alloyed Stainless Steel) Composition: • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 16.0 – 18.0% • Nickel (Ni): 10.0 – 14.0% • Molybdenum (Mo): 2.0 – 3.0% Applications: Suited for mildly corrosive environments including water filtration systems and food-grade tanks. 3. 321 (Titanium-Stabilized Stainless Steel) Composition: • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 17.0 – 19.0% • Nickel (Ni): 9.0 – 12.0% • Titanium (Ti): ≥ 5x(C+N) Applications: Applicable in moderately high temperatures or where intergranular corrosion resistance is important, such as thermal pipelines and heating systems. Applications of DIN 2573 Stainless Steel Flanges: • Water Distribution and Treatment Systems: Used in potable and waste water systems, ensuring non-reactive and rust-resistant performance. • HVAC and Building Installations: Employed in air ducts, chilled water lines, and other HVAC components where low-pressure performance is sufficient. • Food and Beverage Processing: Chosen for hygienic piping setups in non-pressurized fluid transfer applications. • Industrial Utility Lines: Integrated into auxiliary piping systems for lubricants, cooling water, and drainage. • Agricultural and Irrigation Systems: Used in low-pressure pumping and irrigation lines due to their corrosion resistance and ease of installation. Key Features: • Manufactured in compliance with DIN 2573 standard • PN 6 pressure rating suitable for non-critical systems • Excellent corrosion resistance with hygienic surface options • Flat and slip-on configurations for simplified assembly • Available in 304, 316, 321, and other stainless steel grades Conclusion: DIN 2573 Stainless Steel Flanges PN 6 by Ladhani Metal Corporation offer a cost-effective and reliable solution for low-pressure applications. Their corrosion-resistant material, ease of installation, and compliance with international standards make them ideal for various general-purpose industrial systems. For tailored configurations, specific material grades, or technical support, contact Ladhani Metal Corporation.