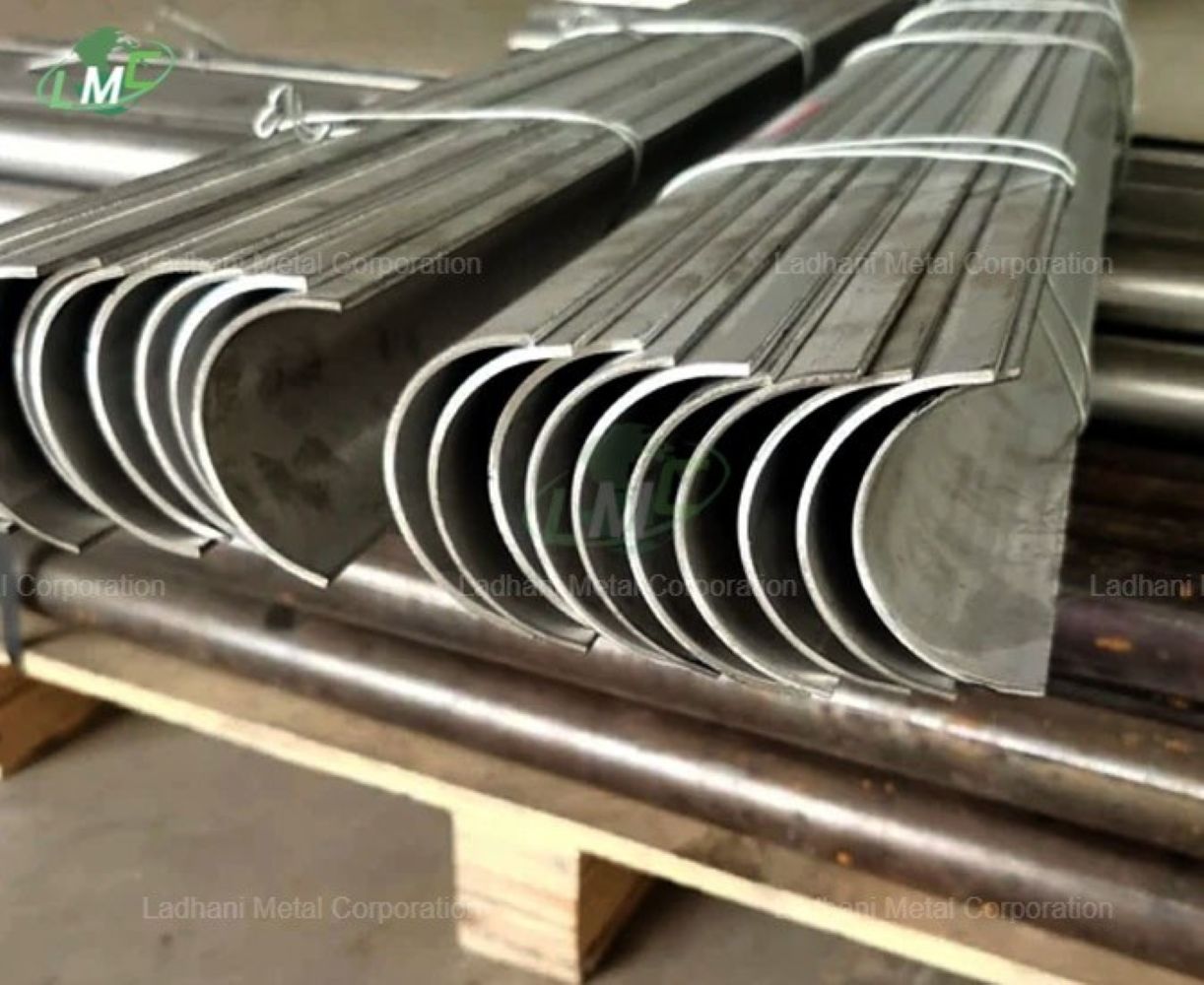

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are precision-engineered solutions designed to protect boiler, superheater, and heat exchanger tubes from erosion, scaling, slag buildup, and high-temperature corrosion. These shields are widely used in systems that operate under extreme thermal and mechanical stress, particularly in industries such as power generation, petrochemical processing, and waste heat recovery. The half-round design ensures easy and secure installation over straight or curved tube surfaces, helping to extend service life and reduce operational downtime. SS 304 U Type Inner Half Round Tube Shield The SS 304 U Type Inner Half Round Tube Shield is manufactured from austenitic stainless steel grade 304, which contains chromium and nickel as its primary alloying elements. This grade offers a combination of good corrosion resistance, oxidation resistance, and mechanical strength. The inner U-type configuration is specifically designed to cover the inner arc of U-bend tubes in boilers and heat exchangers, an area that typically experiences accelerated wear due to flue gas turbulence, scaling, and heat stress. • Inner U Type Half Round Tube Shield – Shields the internal curvature of U-bend tubes from corrosion, turbulent flow-induced erosion, and thermal scaling. Ladhani Metal Corporation is a reliable manufacturer, supplier, and exporter of SS 304 U Type Inner Half Round Tube Shields, delivering durable and cost-effective shielding for critical industrial applications. Chemical Composition of SS 304 – Austenitic Stainless Steel • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 18.0 – 20.0% • Nickel (Ni): 8.0 – 11.0% • Iron (Fe): Balance Applications: Ideally suited for clean to mildly corrosive environments, including thermal and chemical plants where moderate oxidation and corrosion resistance is needed under elevated temperatures. Uses • Inner surface protection for U-bend tubes in superheaters and reheaters exposed to turbulent gas flow • Applied in return bends of waste heat recovery boilers (WHRBs) and HRSGs • Installed in curved sections of heat exchangers, steam reformers, and process heaters • Suitable for flue gas ducts, evaporators, and condensers with moderate thermal cycling • Used in chemical and refining systems where steam and mildly acidic gases are present Features • Good corrosion and oxidation resistance – Suitable for a broad range of service conditions • Inner arc coverage – Protects the inner bend area from scaling and erosion caused by turbulent flue gases • Durable performance – Offers dependable protection at temperatures up to 870°C • Precise fit – Fabricated to match the exact bend radius and tube dimensions for a secure installation • Easy mounting – Can be installed using clamps, stainless steel banding, or tack welding • Cost-effective solution – Provides a balance of performance, longevity, and affordability for standard industrial applications Applications • thermal power plants – Used in inner U-bends of superheaters and economizers to minimize scaling and erosion • petrochemical industries – Shields inside tube curves exposed to combustion gases and steam • waste heat systems – Protects internal arcs of curved tubes in WHRBs and HRSGs from slag and heat damage • chemical and refinery plants – Provides resistance against moderate levels of corrosion in return bends • industrial heating systems – Ensures extended tube life in furnaces, heat exchangers, and flue gas systems Conclusion The SS 304 U Type Inner Half Round Tube Shield by Ladhani Metal Corporation – manufacturer, supplier, and exporter – is a practical and reliable solution for protecting the inner arc of U-bend tubes in moderate to high-temperature industrial environments. With its balance of corrosion resistance, mechanical durability, and ease of installation, this shield is ideal for a wide range of power and process industry applications. For technical consultation, custom sizes, or quotations, please contact Ladhani Metal Corporation.

Send Message