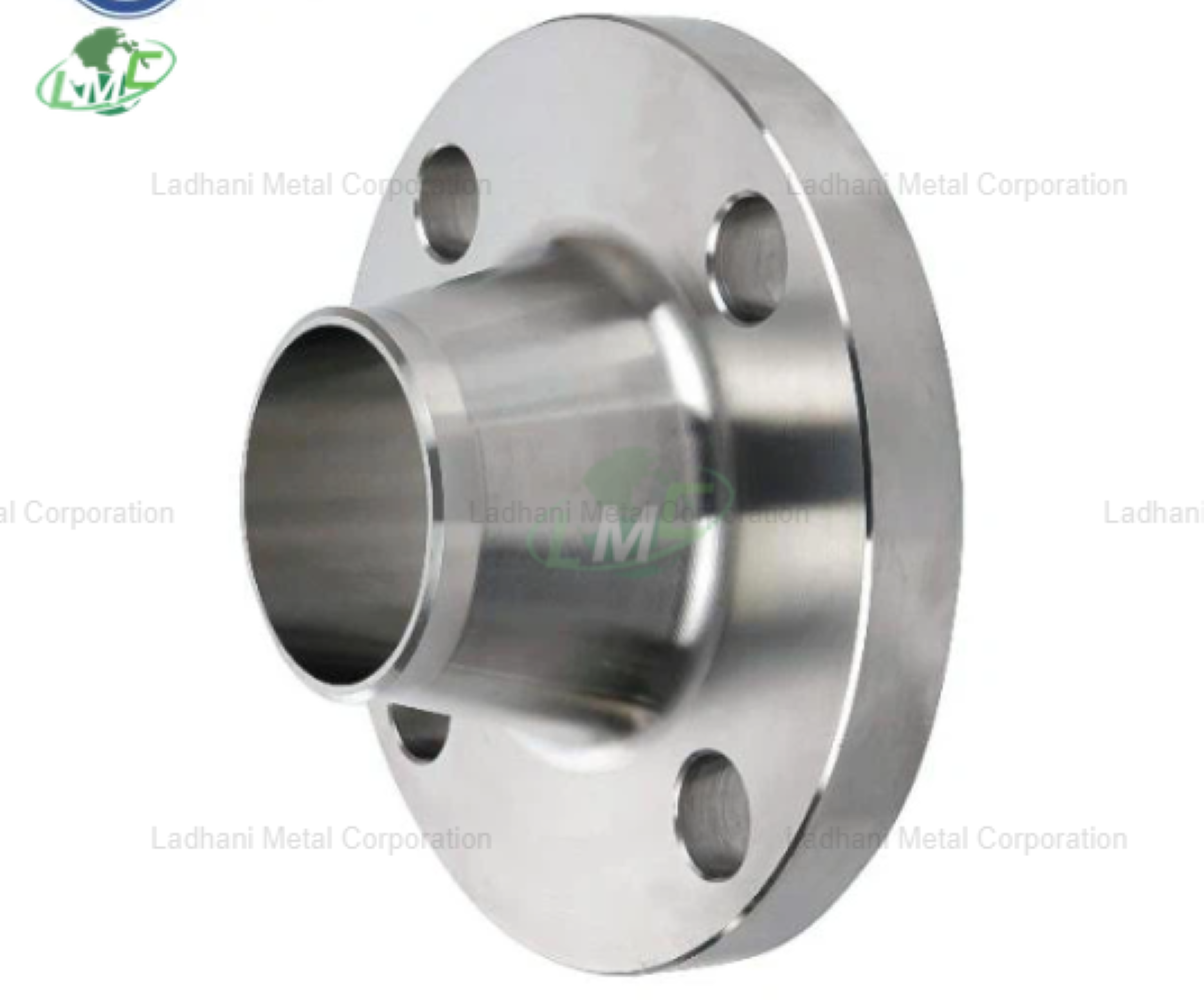

DIN 2630 stainless steel flanges PN 2.5 are precision-fabricated weld neck flanges produced in accordance with the DIN 2630 standard. These flanges are engineered for low-pressure applications up to 2.5 bar (36.25 psi), providing reliable and leak-resistant connections in light-duty and non-critical piping systems. Manufactured from premium stainless steel grades including 304, 316, and 321, they offer excellent corrosion resistance, mechanical stability, and longevity even in mildly corrosive or intermittent industrial environments. Ladhani Metal Corporation is a globally trusted manufacturer and supplier of stainless steel flanges, known for delivering consistent quality and engineering precision. Ladhani Metal Corporation ensures each flange meets relevant industrial standards and environmental requirements. Pressure Rating: • PN 2.5 (2.5 bar / 36.25 psi): Suitable for low-pressure pipeline systems that require basic joint integrity and corrosion resistance. Flange Type: • Weld Neck Flanges Designed with a long tapered hub to support pipe alignment and reduce stress at the base of the flange. Ensures steady flow transition with minimal turbulence. • Flat Face (FF) Flanges Flat face design ensures even gasket compression and is preferred in systems using cast components or soft gasket materials. Stainless Steel Grades and Full Composition: Stainless Steel 304 • Chromium (Cr): 18.0 – 20.0% • Nickel (Ni): 8.0 – 10.5% • Carbon (C): ≤ 0.08% (304), ≤ 0.03% (304L) • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.03% • Iron (Fe): Balance Applications: Ideal for general-purpose low-pressure systems including potable water lines, food-grade applications, and non-aggressive chemical piping. Stainless Steel 316 • Chromium (Cr): 16.0 – 18.0% • Nickel (Ni): 10.0 – 14.0% • Molybdenum (Mo): 2.0 – 3.0% • Carbon (C): ≤ 0.08% (316), ≤ 0.03% (316L) • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.03% • Iron (Fe): Balance Applications: Offers higher corrosion resistance for systems handling chlorinated water, cleaning agents, or mildly acidic substances. Common in pharmaceutical and marine-grade piping. Stainless Steel 321 • Chromium (Cr): 17.0 – 19.0% • Nickel (Ni): 9.0 – 12.0% • Titanium (Ti): ≥ 5 × C (typically 0.20 – 0.70%) • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.03% • Iron (Fe): Balance Applications: Best suited for moderate temperature and corrosion conditions. Often used in low-pressure exhaust lines, thermal processing, and food-grade heat equipment. Applications of DIN 2630 Stainless Steel Flanges PN 2.5: • Water Supply and Treatment Used in potable and greywater systems requiring low-pressure fluid conveyance. • Food and Beverage Industry Ideal for hygienic piping with low flow rates and non-corrosive media. • Chemical Distribution Used in systems handling diluted or non-aggressive chemicals. • HVAC and Ventilation Suited for duct flanges and connections in air-handling systems. Key Features: • Compliant with DIN 2630 standards • PN 2.5 pressure class for low-pressure service • Weld neck design for improved pipe-flange connection • Available in stainless steel grades 304, 316, and 321 • Flat face configuration for even gasket contact • Corrosion-resistant and long-lasting under mild mechanical loads • Suitable for food-grade, chemical, and HVAC systems • Custom sizes, finishes, and material grades available upon request Conclusion: DIN 2630 Stainless Steel Flanges PN 2.5 from Ladhani Metal Corporation are optimized for low-pressure industrial applications where corrosion resistance, hygiene, and operational simplicity are key. Made from high-grade stainless steel materials, these weld neck flanges offer a reliable, economical solution for various sectors including water distribution, food processing, and light chemical service. For custom dimensions, technical consultation, or pricing details, contact Ladhani Metal Corporation today.

Send Message