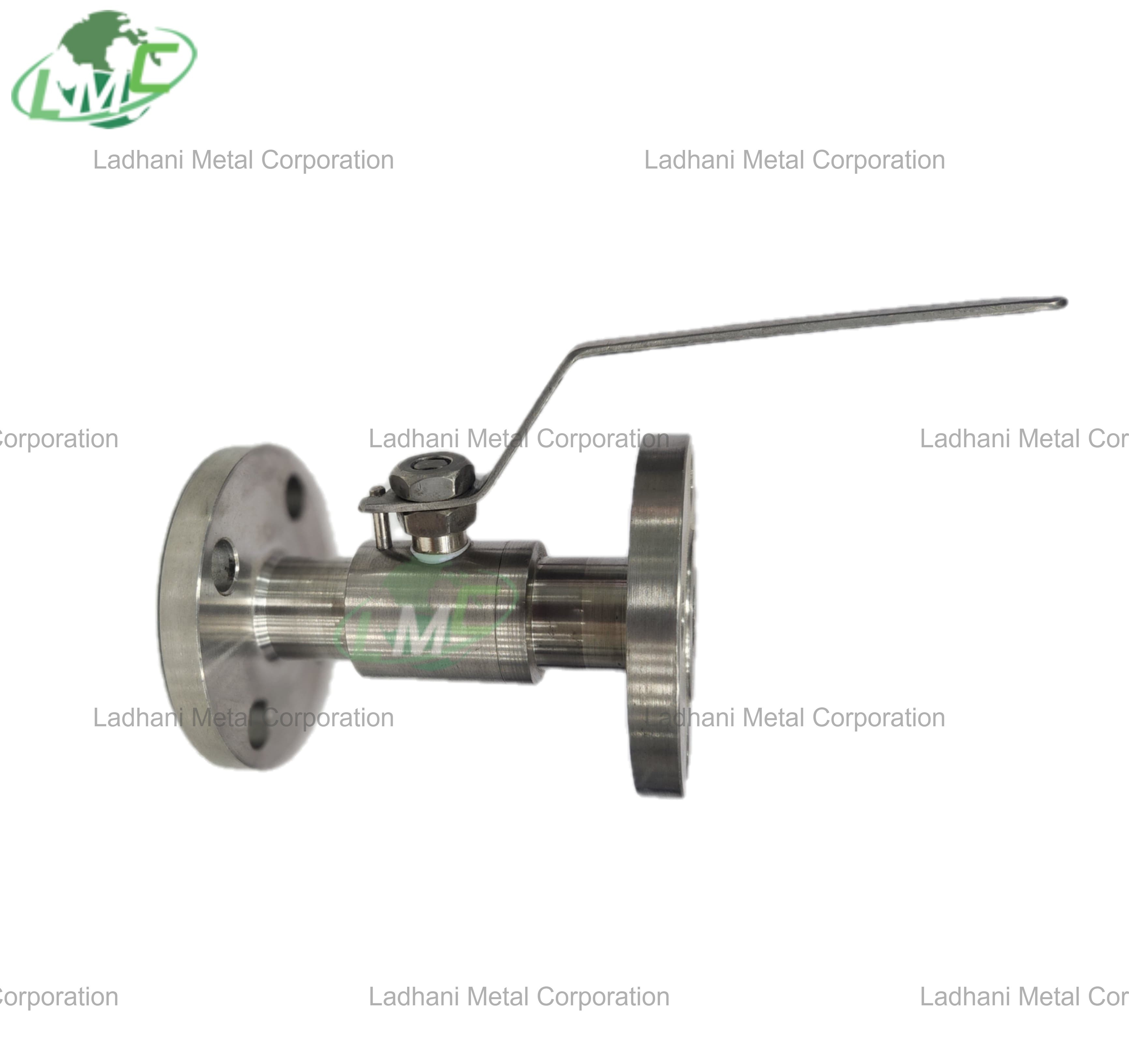

Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of high-quality Flanged Hastelloy Ball Valves. A flanged Hastelloy ball valve is a robust and corrosion-resistant flow control device designed for handling highly aggressive fluids and gases in demanding industrial processes. Built with durable flanged ends, it ensures secure, leak-proof connections and easy installation in high-pressure and high-temperature systems. The valve’s quarter-turn operation allows quick and reliable shut-off, while its Hastelloy alloy construction provides exceptional resistance to oxidizing and reducing chemicals, acids, and chlorides, ensuring long service life and consistent performance. Functions The main functions of a flanged Hastelloy ball valve include: • Regulating and isolating the flow of liquids and gases. • Providing tight shut-off with minimal operating torque. • Ensuring smooth flow with low pressure loss. • Offering quick quarter-turn operation for fast control. • Maintaining excellent corrosion resistance in aggressive chemical environments. • Supporting reliable sealing even under high pressure and temperature conditions. Grades Available Flanged Hastelloy ball valves are available in various grades to meet specific industrial requirements: • Hastelloy C-22 – Provides superior resistance to oxidizing and reducing media, acids, and chlorides. • Hastelloy C-4 – Offers excellent high-temperature stability and oxidation resistance. • Hastelloy C-276 – Known for its outstanding resistance to strong oxidizers, reducing agents, and wet chloride gases. Material Characteristics Hastelloy alloys are nickel-chromium-molybdenum-based materials that offer outstanding corrosion resistance in both oxidizing and reducing environments. They are highly resistant to pitting, crevice corrosion, and stress-corrosion cracking. Their strength and stability under extreme temperature and pressure conditions make them ideal for severe service applications in chemical, marine, and power industries. Applications / Uses Flanged Hastelloy ball valves are widely used in industries where chemical resistance, high performance, and reliability are essential: • Chemical and petrochemical processing plants. • Power generation and energy facilities. • Desalination and water treatment plants. • Marine and offshore systems. • Pharmaceutical and biotechnology industries. • Acid manufacturing and fertilizer plants. • Pollution control and waste management systems. • Pulp and paper manufacturing. Conclusion Flanged Hastelloy ball valves deliver superior performance, durability, and corrosion resistance in the most demanding industrial environments. Their flanged-end design provides secure, leak-proof connections ideal for high-pressure applications, while Hastelloy construction ensures long-lasting reliability in harsh chemical conditions. For any requirement or orders, contact Ladhani Metal Corporation (LMC), a trusted manufacturer, supplier, and exporter of premium Flanged Hastelloy Ball Valves. #Mumbai #Pune #Chennai #Hyderabad #Ahmedabad #Vadodara #Surat #Rajkot #Ankleshwar #Vapi #NaviMumbai #Thane #Kolhapur #Nagpur #Indore #Bhopal #Delhi #Noida #Gurgaon #Faridabad #Kolkata #Howrah #Bhubaneswar #Rourkela #Jamshedpur #Ranchi #Patna #Visakhapatnam #Vijayawada #Bengaluru #Mangalore #Kochi #Coimbatore #Tiruchirappalli #Hosur #Tuticorin #Jamnagar #Bharuch #Dahej #Gandhidham #Mundra #Panipat #Ludhiana #Chandigarh #Amritsar #Jaipur #Udaipur #Kanpur #Lucknow #Haridwar #Dehradun #Silvassa#HastelloyBallValve #HastelloyBallValveManufacturer #HastelloyBallValveSupplier #HastelloyBallValveExporter #HastelloyBallValveIndia #IndustrialHastelloyBallValve #HastelloyC22BallValve #HastelloyC276BallValve #HastelloyC4BallValve #FlangedHastelloyBallValve #ThreadedHastelloyBallValve #HighPerformanceHastelloyBallValve #CorrosionResistantHastelloyBallValve #ChemicalProcessHastelloyBallValve #MarineGradeHastelloyBallValve #OffshoreHastelloyBallValve #OilAndGasHastelloyBallValve #DesalinationHastelloyBallValve #PharmaceuticalHastelloyBallValve #BiotechHastelloyBallValve #IndustrialFlowControlHastelloyBallValve #AcidResistantHastelloyBallValve #HighTemperatureHastelloyBallValve #NickelAlloyHastelloyBallValve #PneumaticHastelloyBallValve #ElectricActuatedHastelloyBallValve #ManualHastelloyBallValve #HydraulicHastelloyBallValve #ANSIStandardHastelloyBallValve #ASMEStandardHastelloyBallValve #Class150HastelloyBallValve