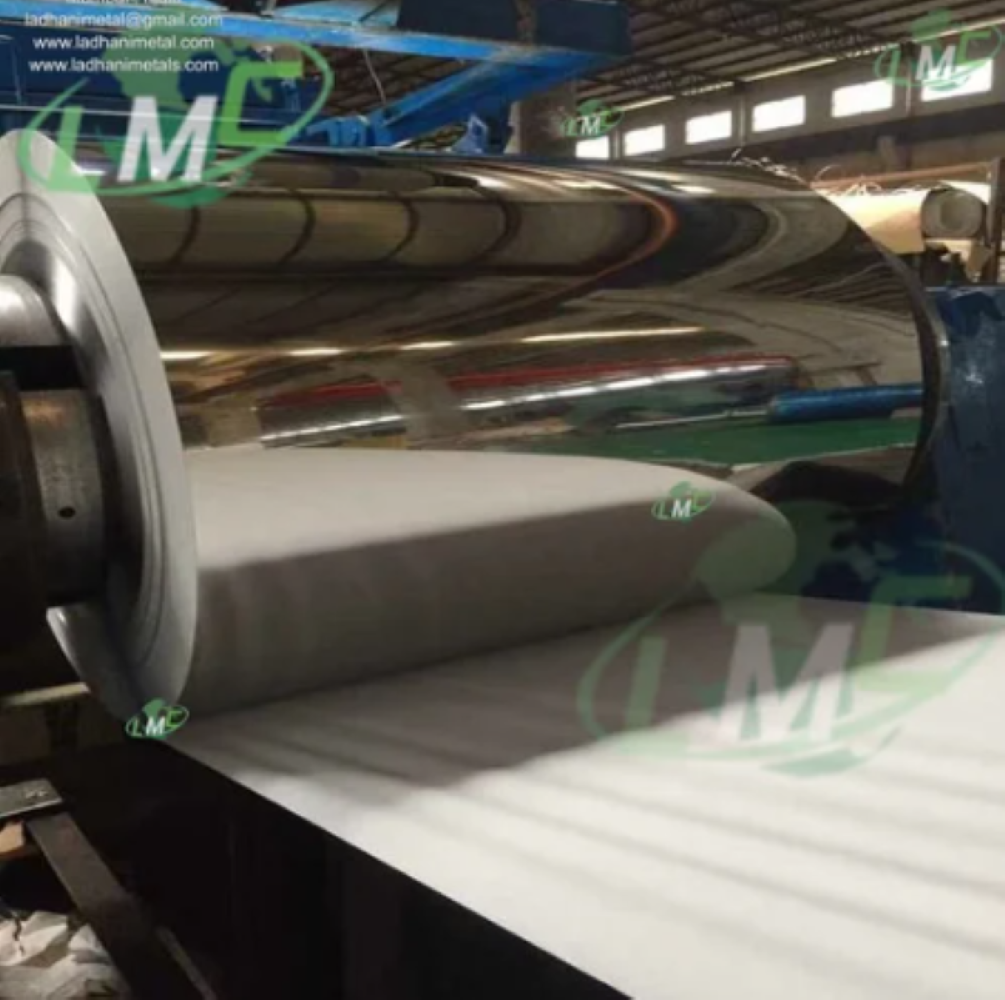

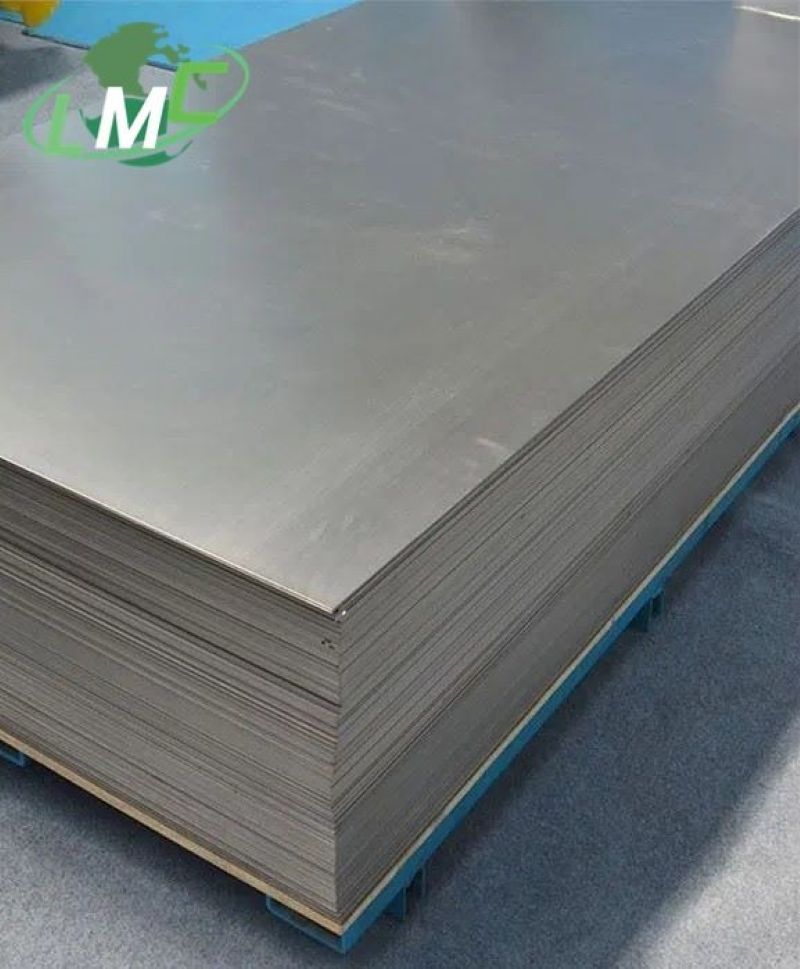

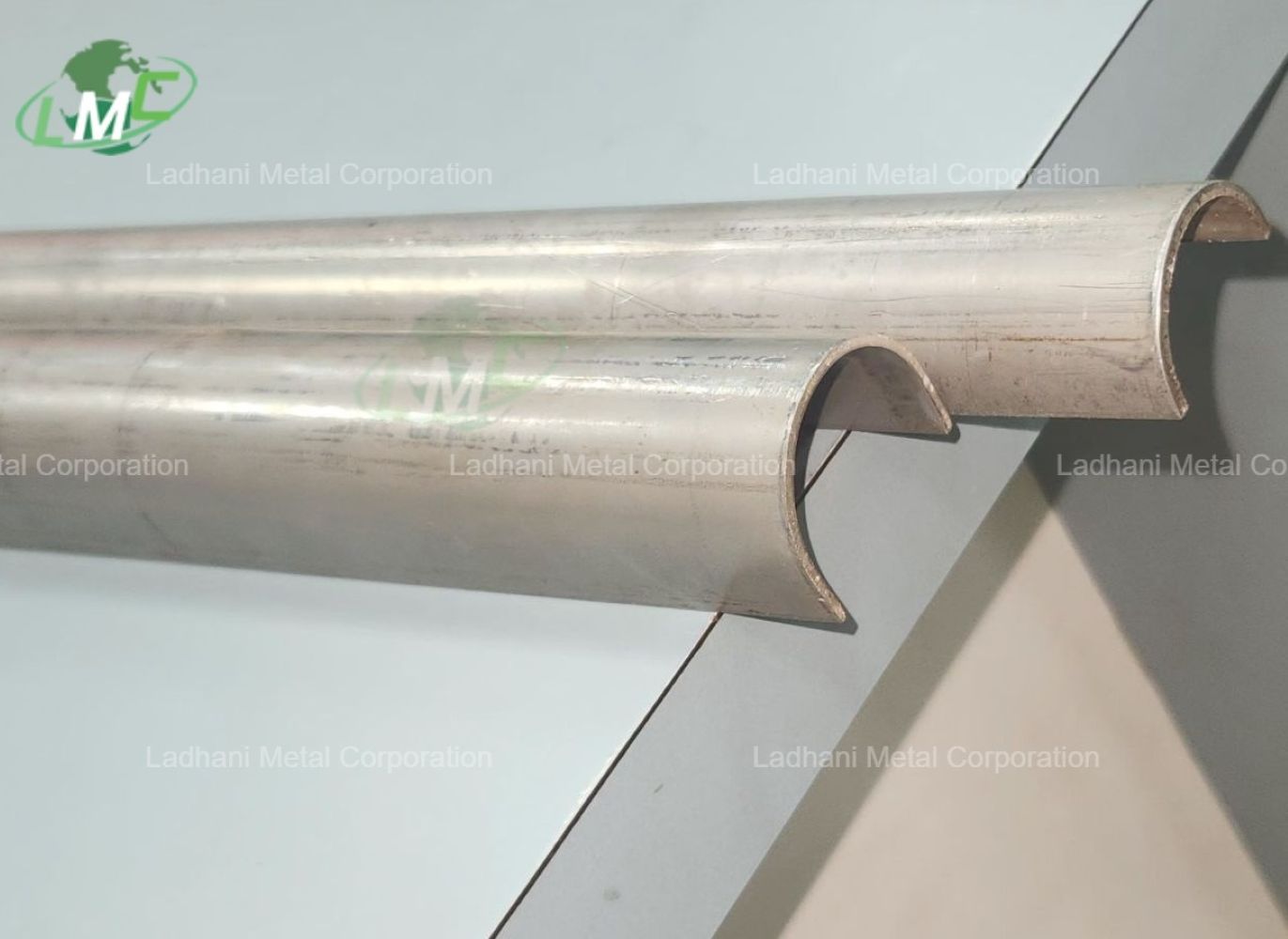

EN 10088 SS X3CrNb17 is a ferritic stainless steel grade containing approximately 17% chromium and stabilized with niobium (columbium). The niobium addition enhances resistance to intergranular corrosion, improves weldability, and provides excellent mechanical stability under heat exposure. This grade offers a strong balance of corrosion resistance, formability, and oxidation resistance, making it suitable for components that require both durability and surface quality. Ladhani Metal Corporation is a reputed manufacturer, supplier, and exporter of EN 10088 SS X3CrNb17 Strip, as well as Sheet, Plate, and Coil. Our X3CrNb17 stainless steel strips are available in various thicknesses, widths, and surface finishes, produced to international quality standards. These strips are ideal for use in automotive, construction, and industrial equipment manufacturing. Forms Available: strip, sheet, plate, coil Chemical Composition (%): • Carbon (C): ≤ 0.05 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 1.00 • Phosphorus (P): ≤ 0.040 • Sulphur (S): ≤ 0.015 • Chromium (Cr): 16.0 – 18.0 • Niobium (Nb): ≥ 10 × C and ≤ 1.00 Mechanical Properties: • Tensile Strength: 430 – 630 MPa • Yield Strength (0.2% Proof): ≥ 250 MPa • Elongation: ≥ 20% • Hardness (HB): ≤ 200 Key Features: • Excellent resistance to oxidation and scaling up to 800°C • Enhanced weldability and formability due to niobium stabilization • Strong protection against intergranular corrosion • High dimensional stability and good surface finish • Magnetic in all conditions Material Characteristics: EN 10088 SS X3CrNb17 Strip offers excellent corrosion resistance in mildly aggressive and oxidizing environments. The addition of niobium prevents carbide precipitation during welding and heat treatment, maintaining mechanical strength and ductility. It performs reliably under thermal cycling, providing stability and resistance to scaling. The material is easy to form, stamp, and weld, making it ideal for manufacturing heat-resistant and structural components. Applications: • Automotive exhaust systems and trim parts • Heat exchangers and furnace components • Building and architectural cladding • Industrial ducts, tanks, and process equipment • Domestic appliances and kitchen equipment Conclusion: Ladhani Metal Corporation supplies premium-quality EN 10088 SS X3CrNb17 Strip, Sheet, Plate, and Coil with superior surface finish, mechanical strength, and dimensional accuracy. Our products are engineered for consistent performance and long service life in industrial and high-temperature applications. For technical specifications or customized requirements, please contact Ladhani Metal Corporation – your dependable partner for stainless steel solutions #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar #EN10088 #EN10088StainlessSteel #En10088SheetPlateCoilStrip #SSSheet #SSPlate #SSCoil #SSStrip #ColdRolledSteel #HotRolledSteel #CustomFabrication #CorrosionResistantSteel #DurableSteel #PrecisionEngineered #EN10088SSManufacturer #EN10088SSSupplier #EN10088SSExporter #ISOApproved #InternationalGradeSteel #HighPerformanceSteel #IndustrialSheet #IndustrialPlate #IndustrialCoil #IndustrialStrip #StainlessSteelSupplier #StainlessSteelManufacturer #StainlessSteelExporter #MetalFabrication #IndustrialApplications #ConstructionMaterials #EngineeringMaterials #OEMApplications #LadhaniMetals #MetalSupplier #MetalExporter #SteelIndustry #MarineSteelApplications #AutomotiveSteelApplications #ChemicalProcessingSteel #FoodProcessingSteel #PharmaGradeSteel #PowerGenerationSteel #HeatExchangerSteel #WaterTreatmentSteel #ArchitecturalSteel #IndustrialEquipmentSteel #CustomMetalSolutions #GlobalExporter #IndianManufacturer #TechnicalSpecifications #MaterialStandards #SteelFabricator #IndustrialSupplier #StainlessSteelIndia #StainlessSteelExporters #IndustrialMetals #MetalSheets #MetalPlates #MetalCoils #MetalStrips #SheetMetalProcessing #SteelFabrication #EngineeringProjects #OEMMetalSolutions #HighQualitySteel #LongLifeMaterial #FabricationMaterials #IndustrialSteel #StainlessSteelProducts