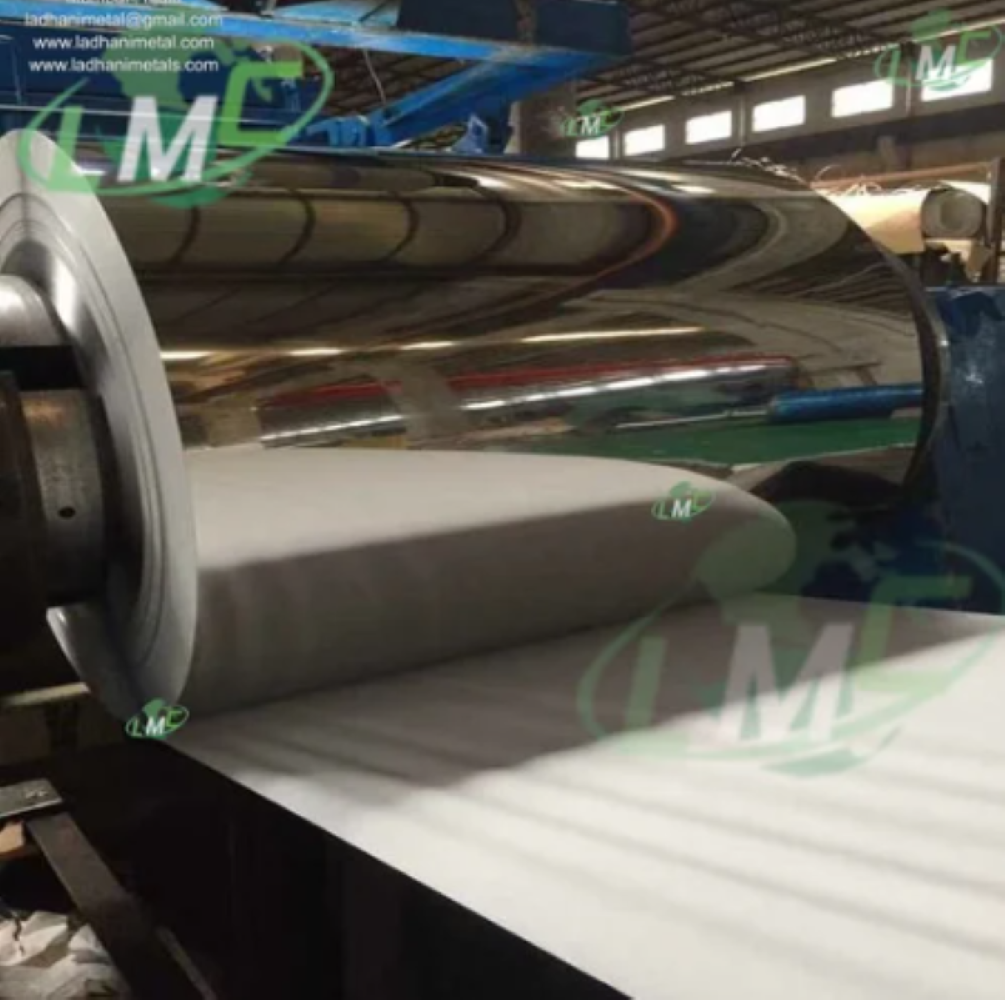

EN 10088 SS X6CrMo17-1 is a ferritic stainless steel grade containing approximately 17% chromium and 1% molybdenum. The addition of molybdenum significantly enhances its resistance to pitting, crevice corrosion, and chloride-induced attack, making it suitable for moderately aggressive environments. This steel combines excellent corrosion resistance, oxidation stability, and good formability, making it a preferred material for components exposed to moisture, salt, and heat. Ladhani Metal Corporation is a leading manufacturer, supplier, and exporter of EN 10088 SS X6CrMo17-1 Coil, as well as Sheet, Plate, and Strip. Our coils are available in various dimensions, tempers, and finishes such as 2B, BA, and No.4 polish, ensuring suitability for both industrial and decorative applications. All products are manufactured in compliance with international quality standards to deliver superior durability and performance. Forms Available: coil, sheet, plate, strip Chemical Composition (%): • Carbon (C): ≤ 0.08 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 1.00 • Phosphorus (P): ≤ 0.040 • Sulphur (S): ≤ 0.015 • Chromium (Cr): 16.0 – 18.0 • Molybdenum (Mo): 0.80 – 1.20 Mechanical Properties: • Tensile Strength: 430 – 650 MPa • Yield Strength (0.2% Proof): ≥ 250 MPa • Elongation: ≥ 20% • Hardness (HB): ≤ 200 Key Features: • Excellent resistance to pitting and crevice corrosion due to molybdenum addition • Superior oxidation and scaling resistance up to 800°C • Good weldability and forming properties • Magnetic structure with high mechanical strength • Enhanced corrosion resistance in chloride-containing environments Material Characteristics: EN 10088 SS X6CrMo17-1 Coil exhibits improved corrosion resistance compared to standard ferritic grades such as X6Cr17, particularly in chloride and acidic environments. The molybdenum addition increases resistance to localized corrosion, while the ferritic structure provides dimensional stability and low thermal expansion. It performs exceptionally well under heat exposure and retains its mechanical properties after repeated thermal cycles. The coil form allows easy processing into strips, panels, and fabricated components for industrial and consumer applications. Applications: • Heat exchangers and condenser tubes • Automotive exhaust components • Food processing and kitchen equipment • Chemical processing and marine equipment • Building facades and decorative panels Conclusion: Ladhani Metal Corporation supplies high-quality EN 10088 SS X6CrMo17-1 Coil, Sheet, Plate, and Strip designed for superior corrosion resistance and long-term reliability. Our products ensure consistent performance across diverse industrial environments. For technical details, specific dimensions, or custom manufacturing inquiries, please contact Ladhani Metal Corporation – your trusted partner for stainless steel solutions. #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar #EN10088 #EN10088StainlessSteel #En10088SheetPlateCoilStrip #SSSheet #SSPlate #SSCoil #SSStrip #ColdRolledSteel #HotRolledSteel #CustomFabrication #CorrosionResistantSteel #DurableSteel #PrecisionEngineered #EN10088SSManufacturer #EN10088SSSupplier #EN10088SSExporter #ISOApproved #InternationalGradeSteel #HighPerformanceSteel #IndustrialSheet #IndustrialPlate #IndustrialCoil #IndustrialStrip #StainlessSteelSupplier #StainlessSteelManufacturer #StainlessSteelExporter #MetalFabrication #IndustrialApplications #ConstructionMaterials #EngineeringMaterials #OEMApplications #LadhaniMetals #MetalSupplier #MetalExporter #SteelIndustry #MarineSteelApplications #AutomotiveSteelApplications #ChemicalProcessingSteel #FoodProcessingSteel #PharmaGradeSteel #PowerGenerationSteel #HeatExchangerSteel #WaterTreatmentSteel #ArchitecturalSteel #IndustrialEquipmentSteel #CustomMetalSolutions #GlobalExporter #IndianManufacturer #TechnicalSpecifications #MaterialStandards #SteelFabricator #IndustrialSupplier #StainlessSteelIndia #StainlessSteelExporters #IndustrialMetals #MetalSheets #MetalPlates #MetalCoils #MetalStrips #SheetMetalProcessing #SteelFabrication #EngineeringProjects #OEMMetalSolutions #HighQualitySteel #LongLifeMaterial #FabricationMaterials #IndustrialSteel #StainlessSteelProducts