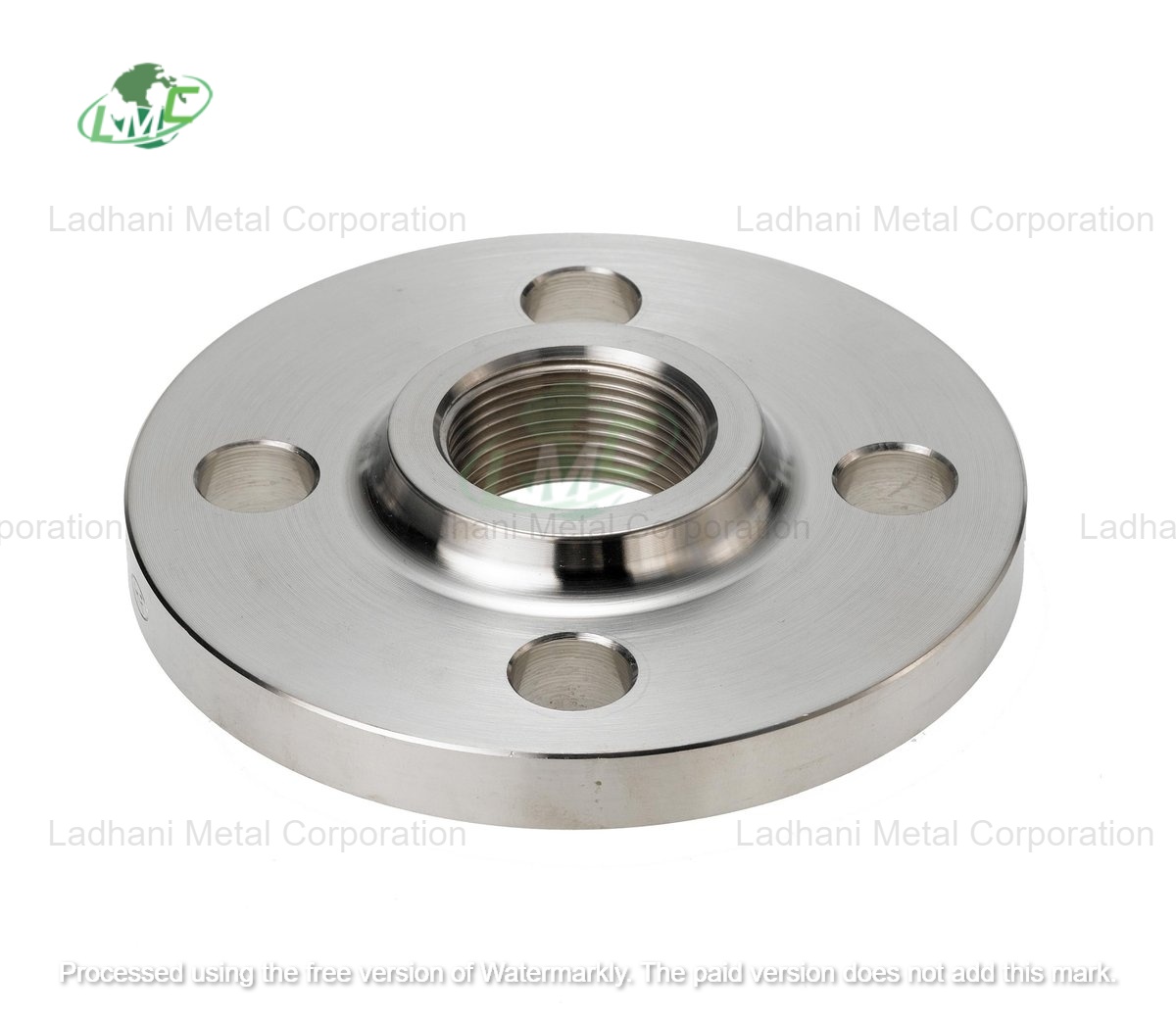

DIN 2568 Duplex Steel Flanges PN 64 are high-performance threaded flanges manufactured from premium duplex stainless steel, engineered to provide superior strength and corrosion resistance in demanding high-pressure environments. Designed in accordance with DIN 2568 standards, these flanges combine the benefits of both austenitic and ferritic stainless steels, delivering excellent mechanical properties, exceptional resistance to stress corrosion cracking, and outstanding durability in aggressive media. Ladhani Metal Corporation is a leading manufacturer and exporter of duplex flanges, supplying components that meet stringent international quality and dimensional standards. The threaded design offers efficient, weld-free assembly and disassembly, making these flanges ideal for systems that require easy maintenance access in chemically harsh or offshore environments. Pressure Rating: • PN 64 (64 bar / 928 psi): Specially designed for use in high-pressure applications involving corrosive media, temperature fluctuations, and mechanical stress. Flange Types: • Threaded (Screwed) Flanges Enable quick connection and removal, suitable for pipelines and assemblies requiring periodic inspection or replacement. • Raised Face (RF) Flanges Enhance sealing performance in high-pressure environments by focusing gasket compression. • Flat Face (FF) Flanges Used in conjunction with flat-faced valves or equipment, especially where gasket alignment and load distribution are crucial. • Forged Threaded Flanges Deliver high strength, superior pressure resistance, and dimensional precision. • Custom-Machined Flanges Offered in a wide variety of sizes, face types, and duplex steel grades to meet specific project requirements. Available Duplex Grades and Composition: 1. Standard Duplex Stainless Steel Composition: • Chromium (Cr): 21.0 – 23.0% • Nickel (Ni): 4.5 – 6.5% • Molybdenum (Mo): 2.5 – 3.5% • Nitrogen (N): 0.08 – 0.20% • Carbon (C): ≤ 0.030% Applications: Commonly used in chemical processing, marine systems, and power generation due to its excellent resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking. Applications of DIN 2568 Duplex Flanges: • Offshore and Marine Engineering: Used in subsea equipment, pipelines, and ballast systems exposed to chloride-rich environments. • Chemical Processing Plants: Withstands corrosive acids, alkalis, and solvents commonly encountered in aggressive chemical processes. • Desalination and Water Treatment: Used in high-salinity applications, such as RO systems and brine discharge lines. • Pulp and Paper Industry: Resists acidic liquors and bleach chemicals in harsh production environments. • Oil and Gas Industry: Employed in pipelines, separators, and injection systems operating under high pressure and exposure to sour service. Key Features: • Designed to DIN 2568 standards • Rated for PN 64 high-pressure service • Combines high mechanical strength and corrosion resistance • Threaded design supports easy, non-welded installation and maintenance • Excellent resistance to pitting, crevice corrosion, and chloride stress cracking • Supplied with full material traceability, test certificates, and quality documentation • Available with custom coatings, surface finishes, and machining options Conclusion: DIN 2568 Duplex Steel Flanges PN 64 from Ladhani Metal Corporation offer a robust and reliable solution for high-pressure, corrosive, and mechanically demanding systems. Their dual-phase microstructure ensures superior performance across a wide range of industrial applications. For custom dimensions, material consultations, or technical assistance, contact Ladhani Metal Corporation today.