U Type Outer Half Round Tube Shield

Half Round Tube Shield

Half Round Tube Shields by Ladhani Metal Corporation are precision-engineered components used to protect boiler and heat exchanger tubes from erosion, scaling, and high-temperature corrosion. These shields are widely applied in industrial systems exposed to thermal cycling, aggressive gases, and particulate flow. Their half-round shape allows for simple and secure installation over straight or curved tube surfaces, extending tube life and reducing maintenance needs.

SS 310 U Type Outer Half Round Tube Shield

The SS 310 U Type Outer Half Round Tube Shield is made from high-temperature austenitic stainless steel, offering exceptional resistance to oxidation, scaling, and thermal fatigue. This outer U-type configuration is designed specifically to protect the outer curvature of U-bend tubes in extreme heat environments, such as boilers, superheaters, reformers, and heat exchangers. The high chromium and nickel content in SS 310 ensures superior performance under cyclic heating and in the presence of oxidizing and carburizing gases.

• Outer U Type Half Round Tube Shield – Provides a protective barrier over the external arc of U-bend tubes, shielding against high-velocity flue gas erosion, slag accumulation, and elevated temperature exposure.

Ladhani Metal Corporation supplies SS 310 U Type Outer Half Round Tube Shields engineered for high-performance applications in power, petrochemical, and thermal processing industries.

Chemical Composition of SS 310 – High-Temperature Austenitic Stainless Steel

• Carbon (C): ≤ 0.25%

• Manganese (Mn): ≤ 2.00%

• Phosphorus (P): ≤ 0.045%

• Sulfur (S): ≤ 0.030%

• Silicon (Si): ≤ 1.50%

• Chromium (Cr): 24.0 – 26.0%

• Nickel (Ni): 19.0 – 22.0%

• Iron (Fe): Balance

Applications: Ideally suited for high-temperature, oxidizing, and mildly carburizing environments such as thermal reactors, flue gas ducts, and furnace systems.

Uses

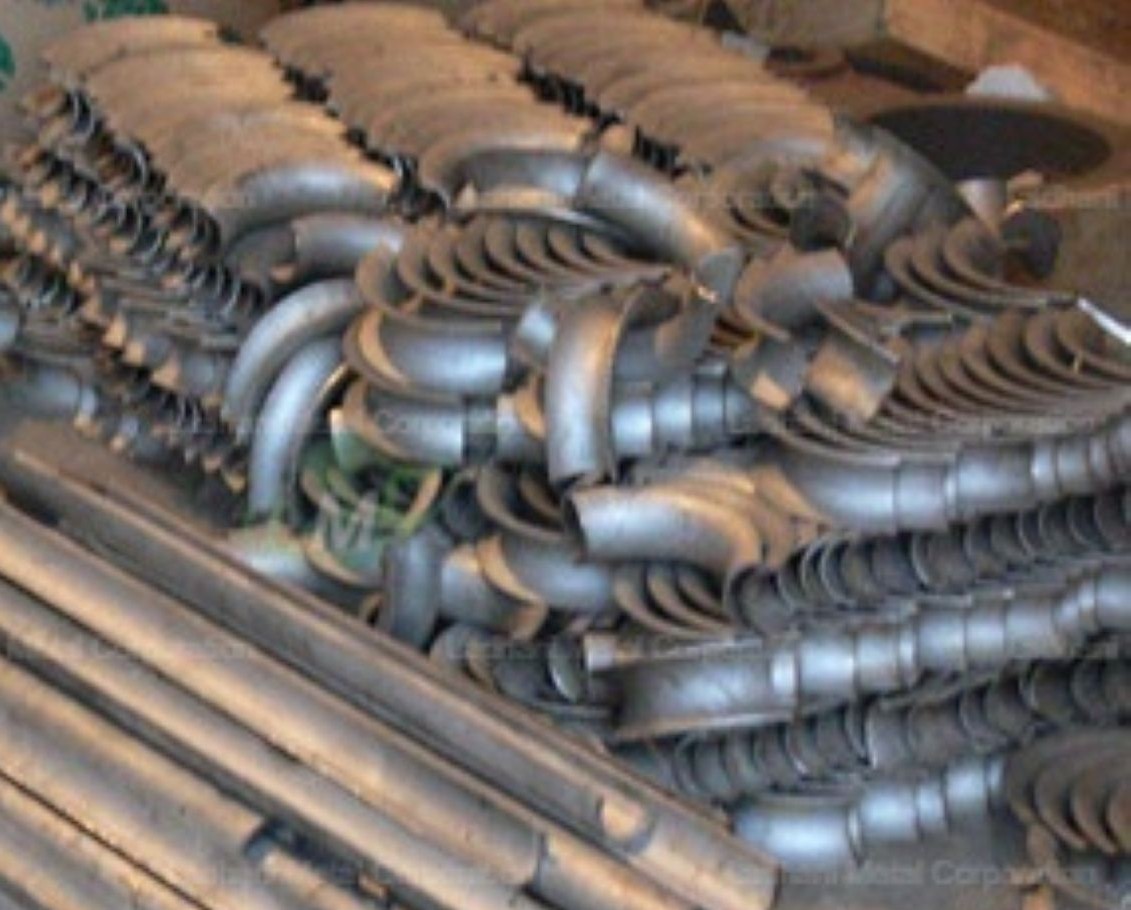

• Protection of outer U-bend surfaces in superheaters and reheaters in thermal and captive power plants

• Shielding return bends in petrochemical and refinery furnaces exposed to flue gas erosion and thermal cycling

• Outer arc protection in waste heat recovery boilers (WHRBs) and HRSGs subjected to slag buildup and gas turbulence

• Used in heat exchanger tubes in high-temperature process gas heating systems and steam reformers

• Suitable for chemical processing, metallurgical, and furnace industries requiring resistance to extreme heat and oxidation

Features

• Excellent high-temperature performance – Withstands continuous service in temperatures up to 1150°C with resistance to scaling and oxidation.

• Superior oxidation and corrosion resistance – High chromium and nickel content ensures long-term protection in oxidizing and carburizing environments.

• Outer bend protection – Specifically shaped for coverage of the most exposed outer arc of U-bend tubes in heat-affected zones.

• Custom fit design – Fabricated to match precise tube diameters and bend radii for tight, stable installation without movement.

• Easy installation – Quick and secure mounting with clamps, stainless steel banding, or tack welding, eliminating the need for system disassembly.

• Long-lasting durability – Reduces erosion, scaling, and heat fatigue, increasing tube service life and reducing maintenance frequency.

Applications

• thermal power plants – Installed on outer arcs of U-bend tubes in superheaters to prevent oxidation, erosion, and thermal cracking in high-temperature zones.

• petrochemical industries – Shields tubes in reformers, process heaters, and crackers exposed to carburizing gases and heat cycling.

• waste heat recovery systems – Protects outer bend surfaces in WHRBs and HRSGs from scale buildup, flue gas impact, and slag abrasion.

• chemical plants – Suitable for use in heat exchangers and high-temperature reactors handling acidic or oxidizing gas streams.

• furnace and incinerator systems – Ideal for radiant tubes, burners, and heat exchanger bends in high-flame and high-velocity environments.

Conclusion

The SS 310 U Type Outer Half Round Tube Shield by Ladhani Metal Corporation is an advanced protective solution for safeguarding U-bend tube sections in high-temperature and aggressive gas environments. With outstanding oxidation resistance, thermal durability, and structural stability, this shield is ideal for power generation, petrochemical, and industrial heating systems. Precision-engineered for a secure fit and ease of installation, it offers long-term performance and reliable protection under severe operating conditions.

For technical consultation, custom orders, or quotations, please contact Ladhani Metal Corporation.

Send Message