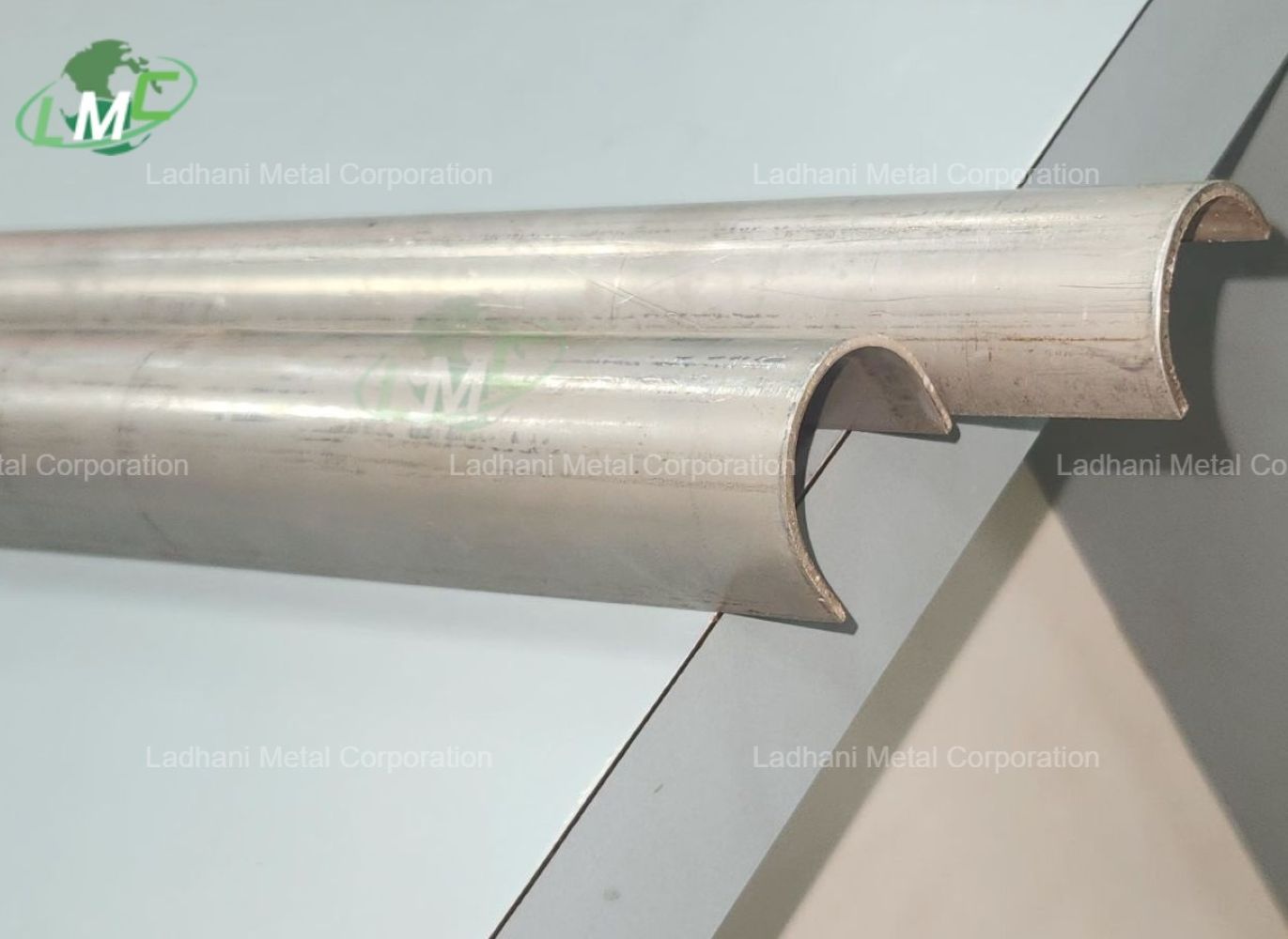

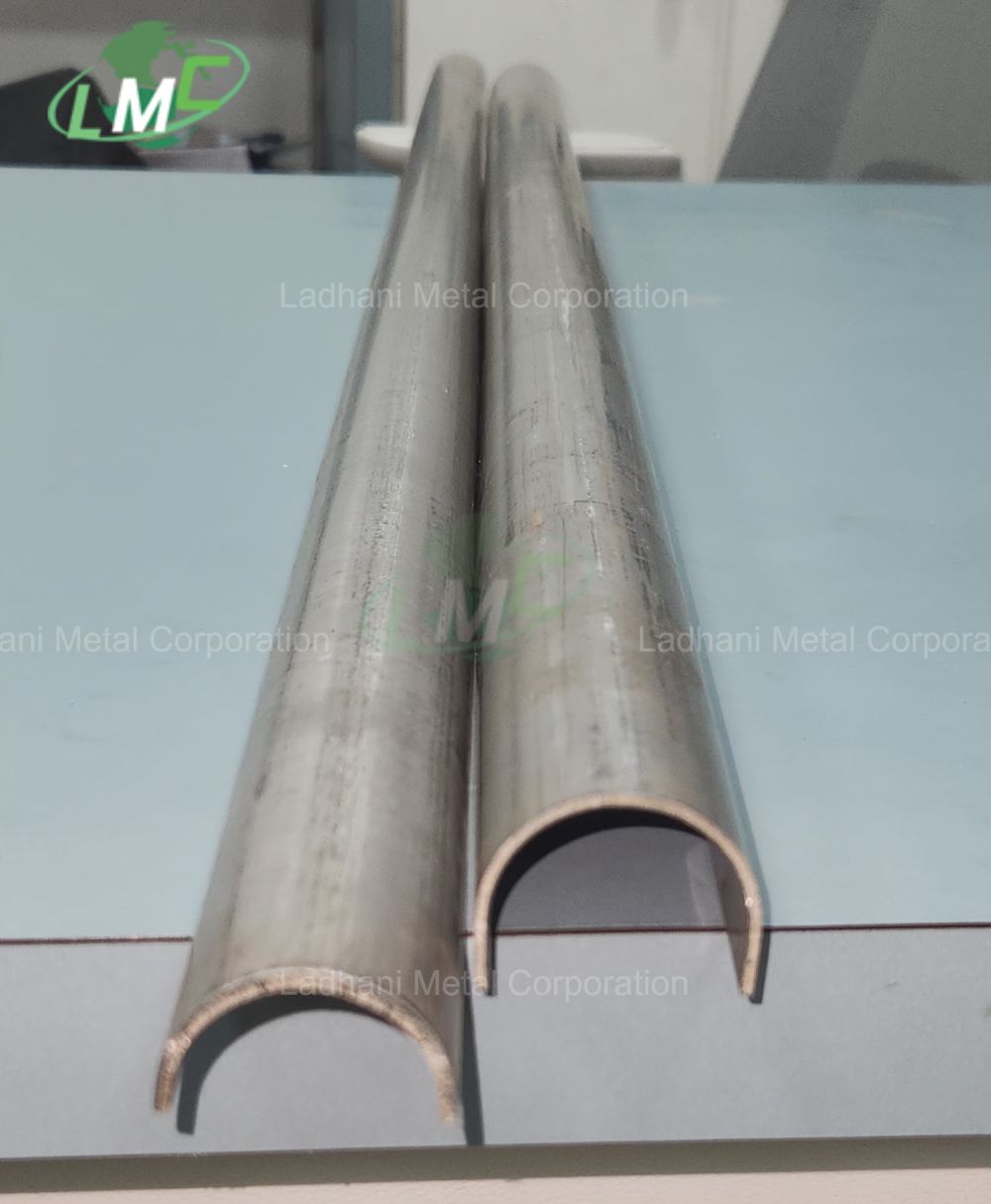

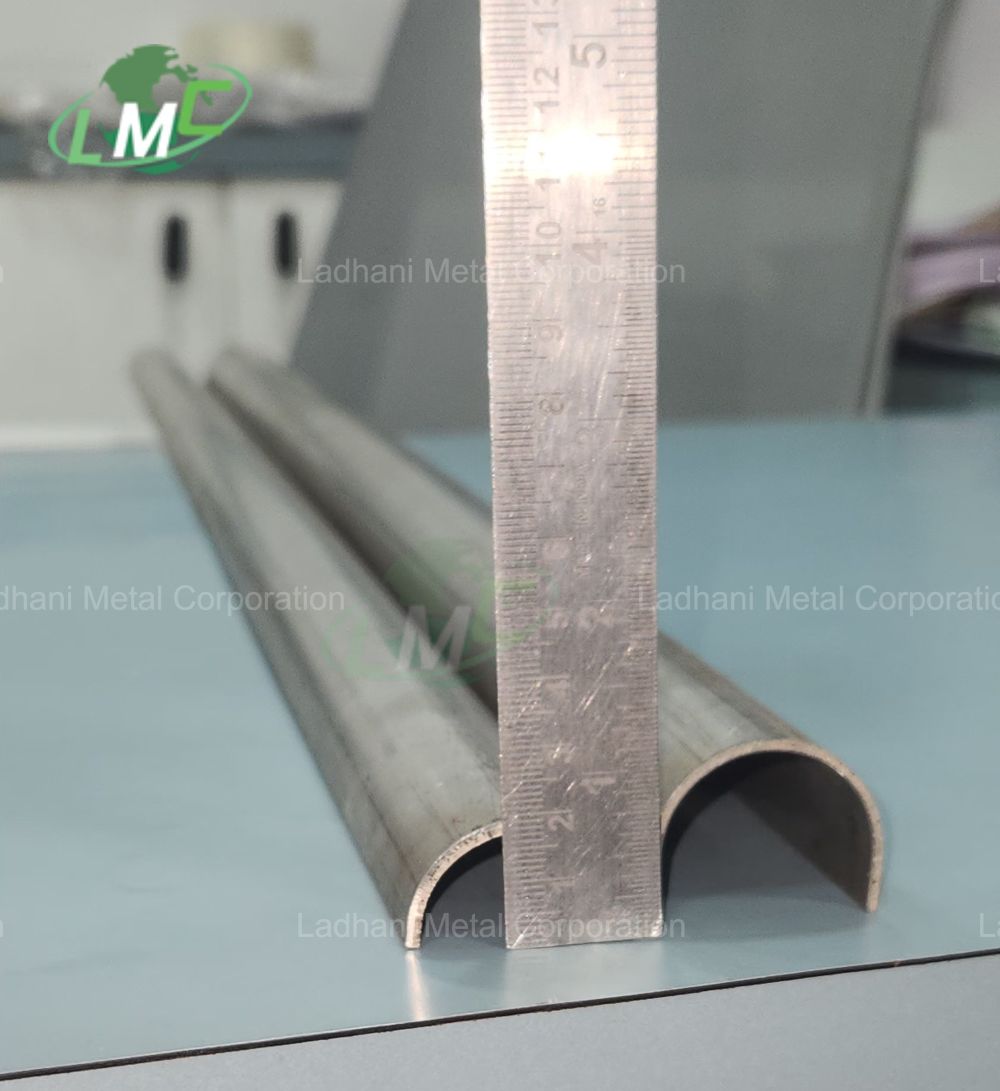

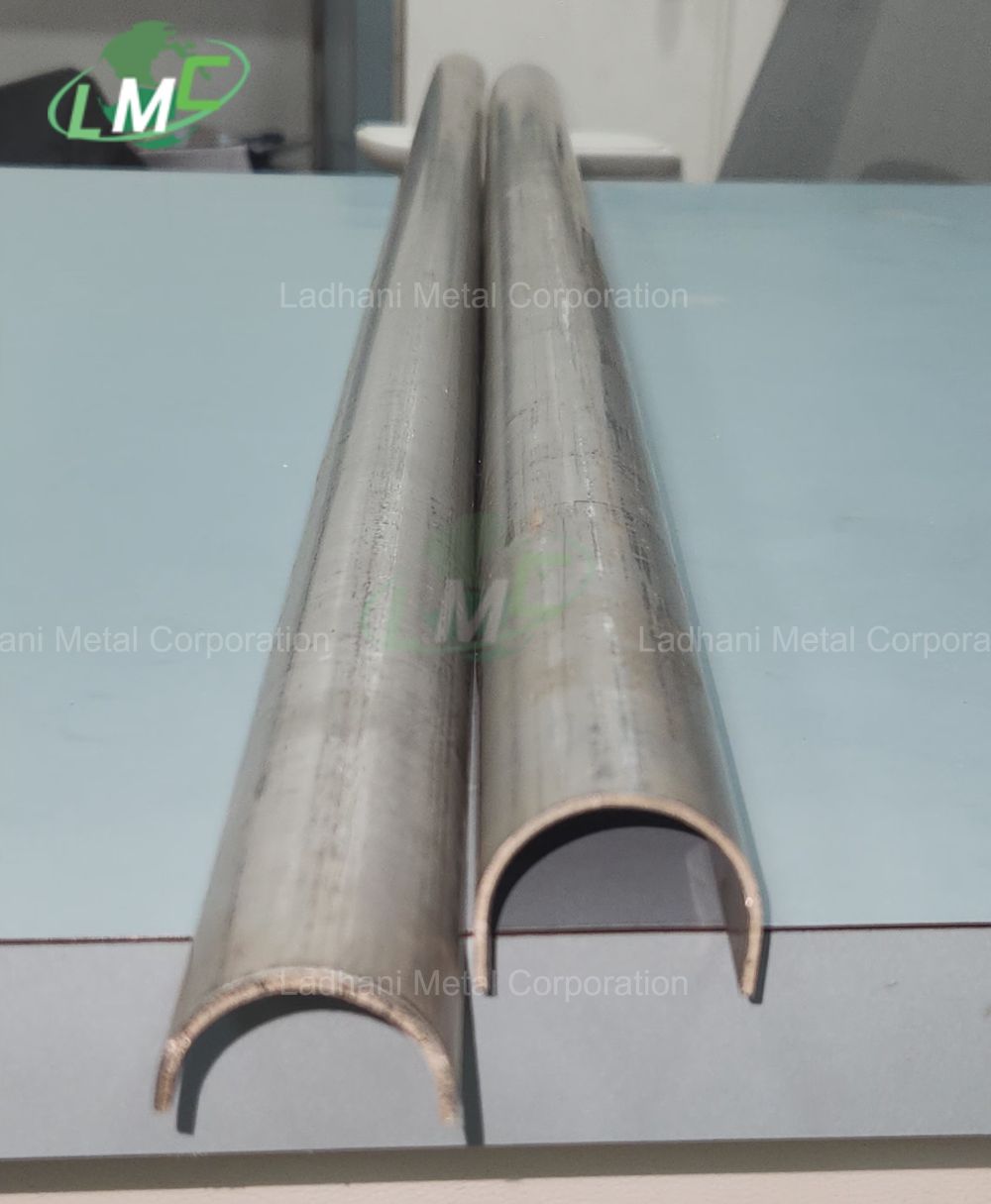

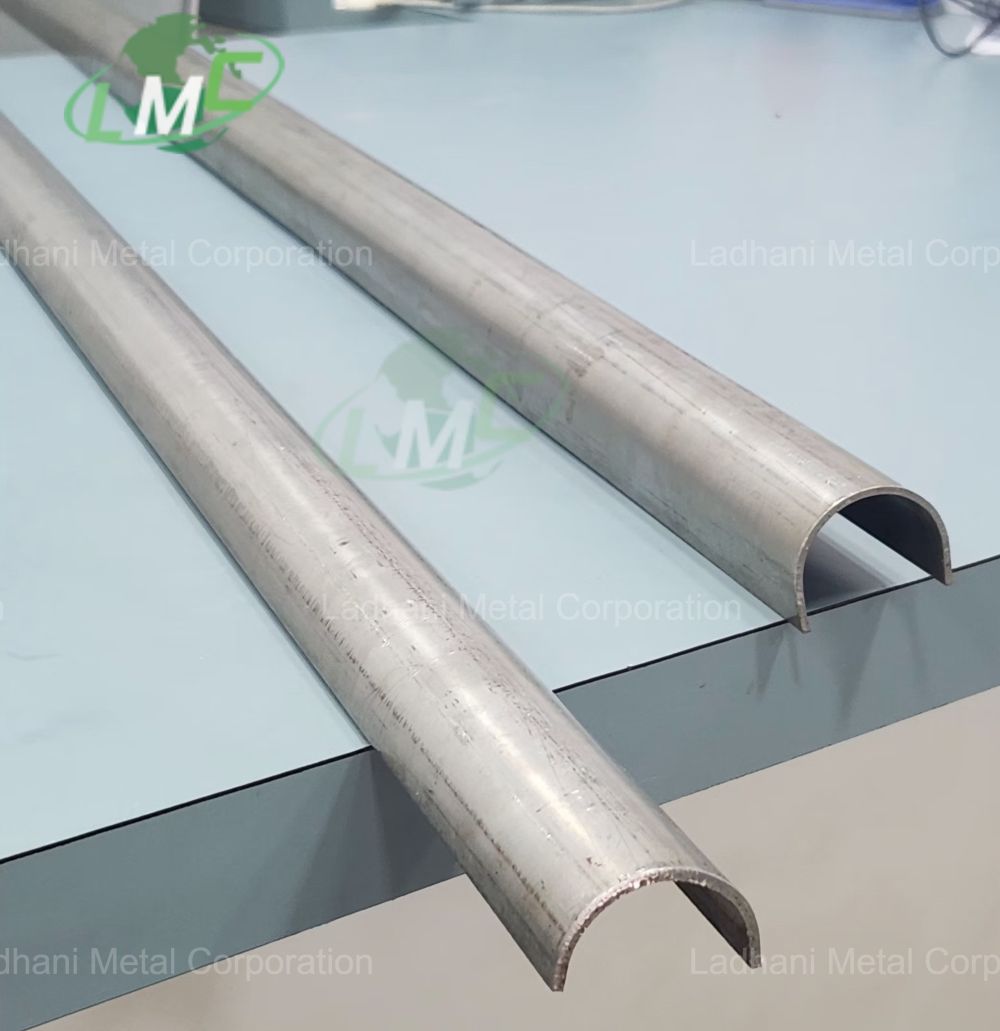

Ladhani Metal Corporation manufactures and supplies SS Tube Sleeves designed to protect boiler tubes in superheaters, reheaters, economizers, waste heat recovery boilers (WHRBs), and heat recovery steam generators (HRSGs). Boiler tubes in these sections are exposed to high-velocity flue gases, abrasive ash particles, and extreme thermal conditions, leading to erosion, oxidation, and premature tube thinning. SS Tube Sleeves act as a protective cover, reducing wear, preventing tube failures, and extending the service life of boiler components. Function of SS Tube Sleeves • Protect boiler tubes from erosion, scaling, and oxidation in high-temperature environments • Reduce damage caused by abrasive ash flow and soot blower jets • Withstand continuous exposure to boiler operating temperatures above 540°C • Improve efficiency and reliability by minimizing tube replacement frequency Ladhani Metal Corporation manufactures, supplies, and exports SS Tube Sleeves in a wide range of diameters, thicknesses, and lengths, ensuring a precision fit for straight tubes, bends, elbows, and U-bends in domestic and international markets. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Power plants, WHRBs, HRSGs, petrochemical heaters, cement industries, and industrial boilers operating under erosive and high-temperature conditions. Uses • Protects reheater, superheater, and economizer tubes from erosion and wear • Shields bends, elbows, and U-bends from soot blower and gas flow impact • Reduces tube scaling and surface damage caused by ash-laden flue gases • Enhances boiler reliability and reduces downtime Features • High resistance to oxidation, erosion, and scaling • Strong thermal stability and creep resistance under cyclic loads • Precision fit for straight and curved tube geometries • Manufactured in stainless steels and high-performance special alloys Applications • Power generation boilers – Long-term erosion and oxidation resistance • WHRBs and HRSGs – Consistent durability under thermal cycling • Industrial and petrochemical heaters – Protection in high-dust atmospheres • Process boilers – Reliable performance with reduced maintenance costs Conclusion SS Tube Sleeves by Ladhani Metal Corporation deliver robust, export-ready protection for boiler tubes in demanding environments. Manufactured in stainless steels SS 304/304L, SS 310/310S, SS 316/316L, SS 410/420/430, and special alloys 1Cr13, 1Cr18Ni9Ti, 1Cr20Ni14Si2, 1Cr25Ni20Si2, Cr23Ni13, and Cr25Ni20, these sleeves are engineered for durability, precision fit, and extended service life.

Send Message