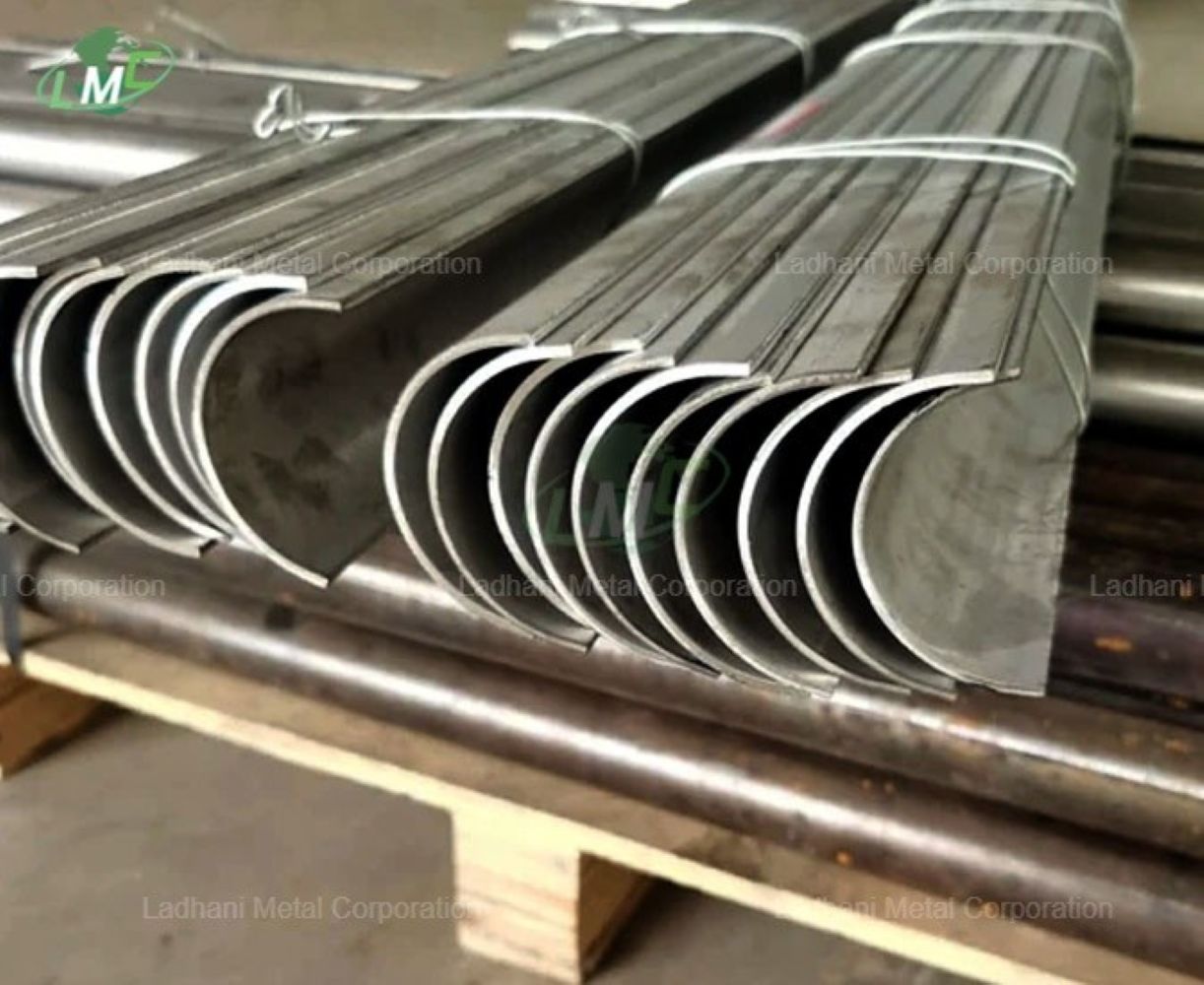

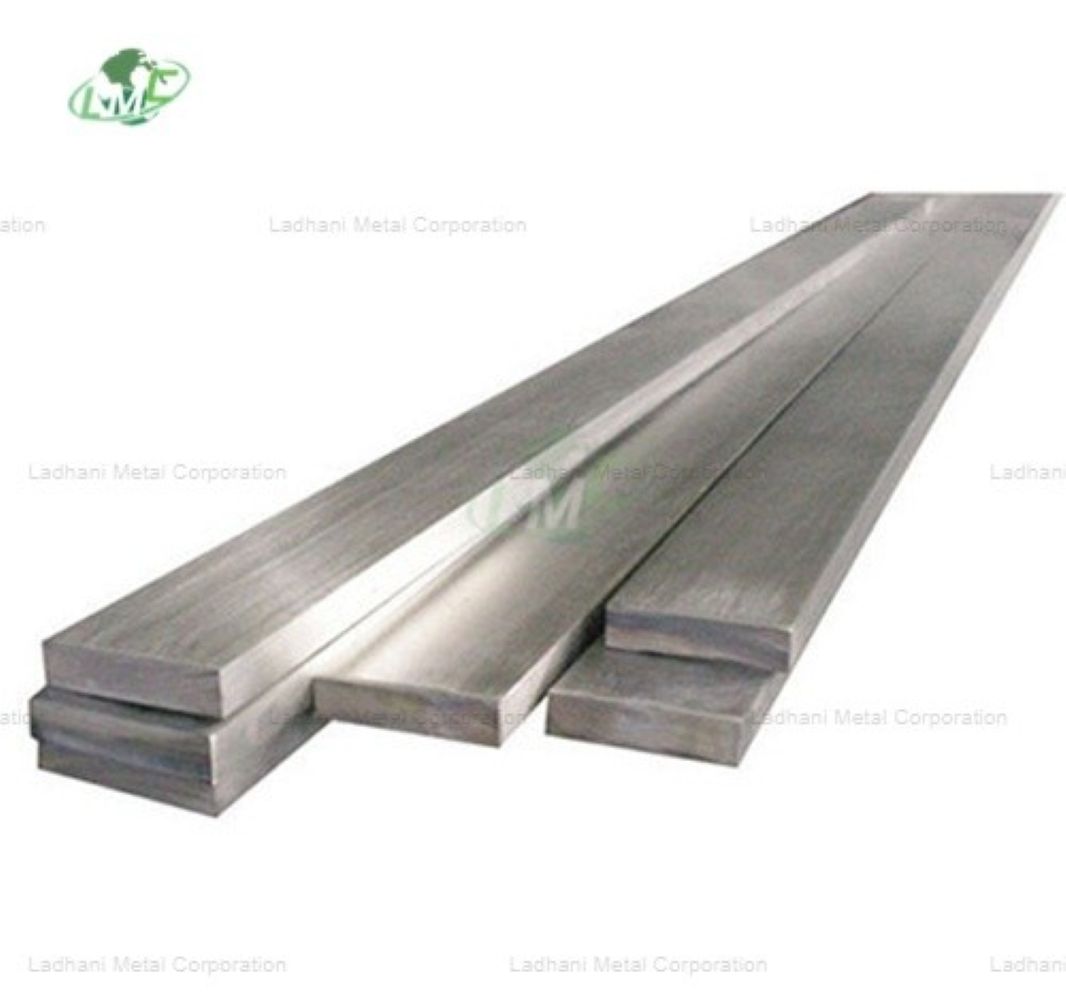

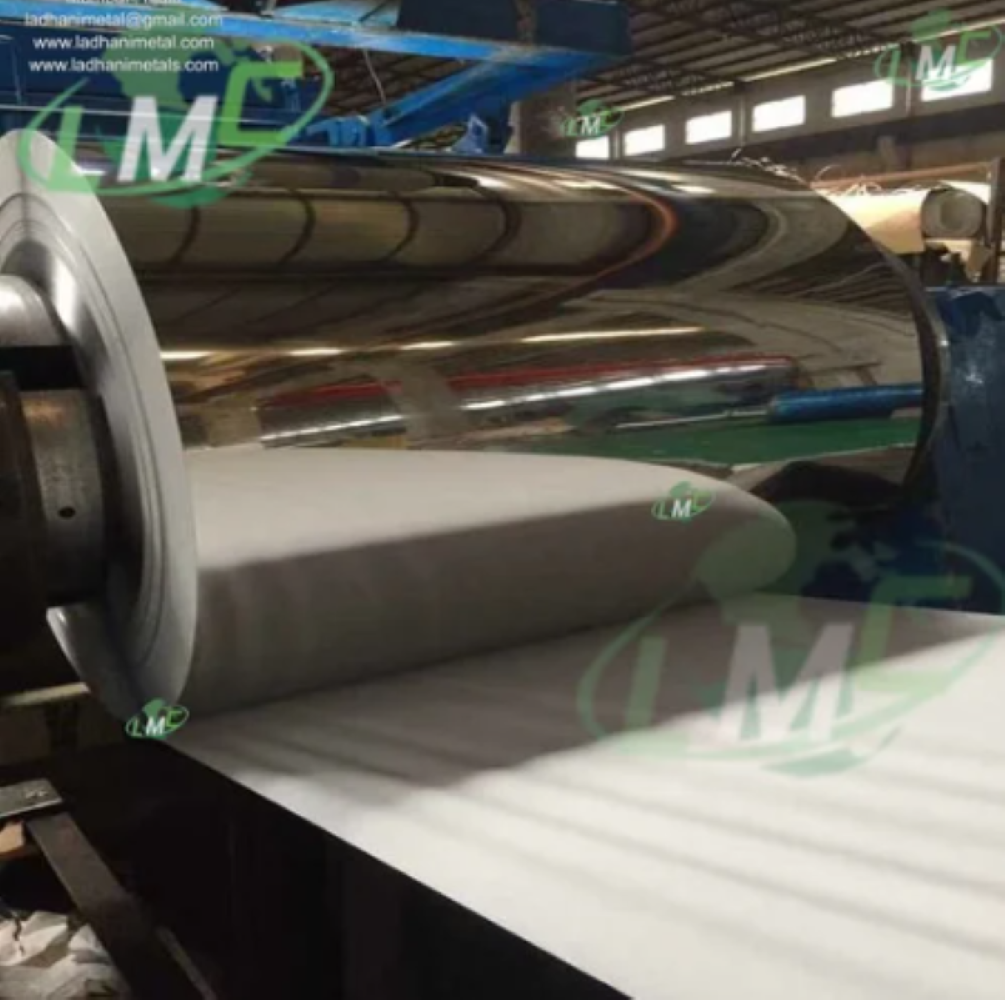

Ladhani Metal Corporation offers Cr23Ni13 Outer Half Round 90 Degree Bend Tube Shields designed to protect the outer arc of U-bends and 90-degree curved tubes used in high-temperature and mildly corrosive environments. The semi-cylindrical design is precision-formed to match the curvature of return bends in boiler and furnace tubing, creating a durable barrier against erosion from high-velocity flue gases, ash abrasion, and soot blower jets. These shields are widely applied in boilers, heat recovery systems, and process heaters where thermal protection and resistance to surface degradation are critical. Ladhani Metal Corporation is a reliable manufacturer, supplier, and exporter of Cr23Ni13 Outer Half Round 90 Degree Bend Tube Shields, offering custom solutions to suit various tube sizes and system configurations. Cr23Ni13 Grade Chemical Composition – Austenitic Stainless Steel • Carbon (C): ≤ 0.12% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 22.0 – 24.0% • Nickel (Ni): 12.0 – 14.0% • Iron (Fe): Balance Uses • Protection of 90-degree return bends in superheaters and reheaters exposed to clean or moderately corrosive flue gas • Applied in WHRB and HRSG systems in power generation and industrial processing • Shields tube curves from oxidation, scaling, and erosive gas flow • Used in high-temperature furnaces and exhaust systems requiring heat resistance and structural stability Features • Reliable heat resistance – Performs effectively under sustained high-temperature exposure • Good corrosion performance – Withstands oxidizing environments and dry gas corrosion • Stable under thermal stress – Resists deformation and fatigue during repeated heating cycles • Precision fit – Manufactured to match specified bend radii for seamless tube coverage • Installation flexibility – Can be clamped, tack welded, or banded for secure placement • Variety of configurations – Available in multiple sizes, thicknesses, and arc lengths Applications • Power and utility boilers – Protects tubing bends in elevated heat zones from surface wear • Petrochemical industry – Used in tube shields for fired heaters and process heat exchangers • Cement and metallurgical plants – Guards heat exchange coils from oxidation and abrasive particles • Industrial thermal systems – Ensures longevity of tubing in dry, high-temperature flue gas environments Conclusion The Cr23Ni13 Outer Half Round 90 Degree Bend Tube Shield by Ladhani Metal Corporation provides dependable thermal and corrosion protection for tube bends in high-temperature systems. With its austenitic composition and balanced alloy content, this shield is ideal for applications requiring durability, thermal reliability, and moderate corrosion resistance. For product customization, technical support, or material inquiries, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield #tubeshieldexporter