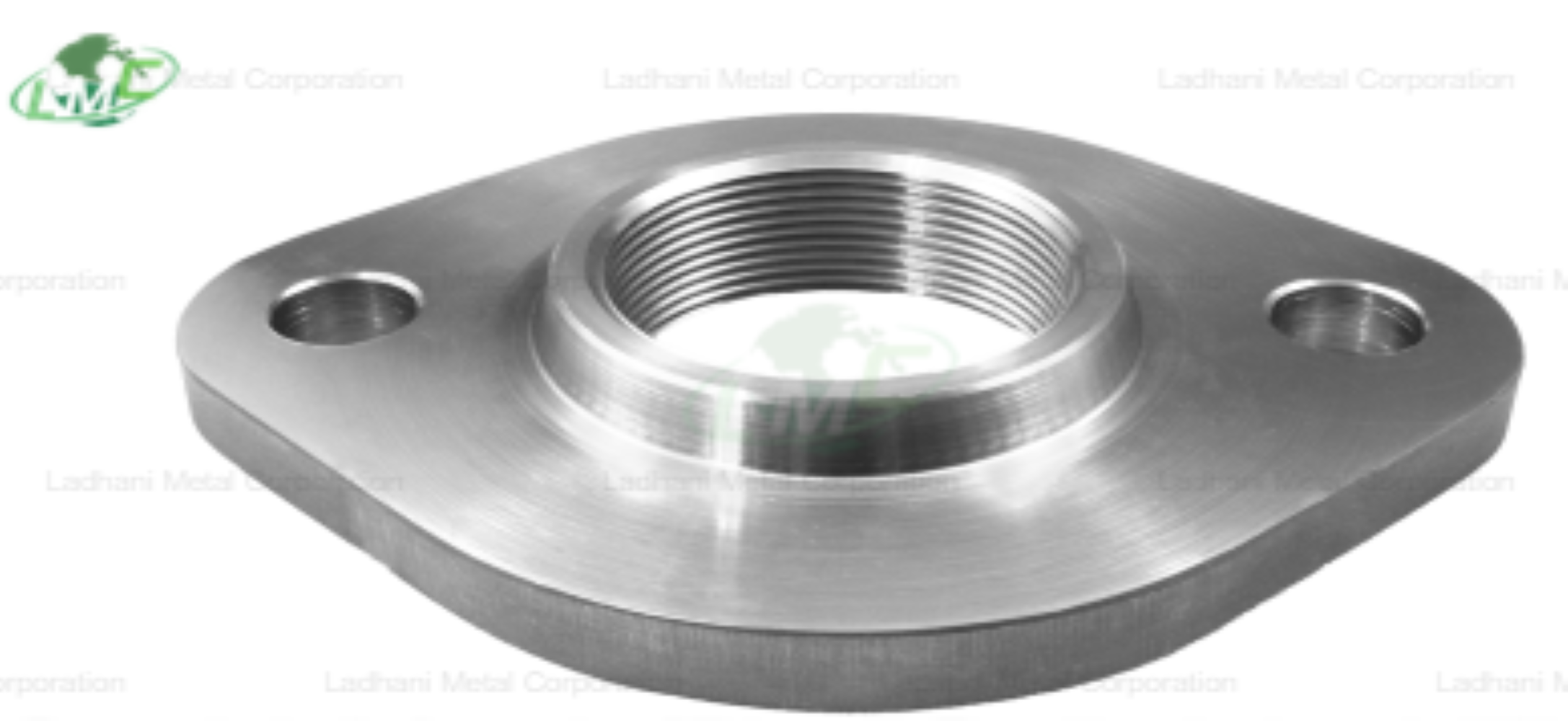

Titanium Flanges

Ladhani Metal Corporation is a trusted manufacturer and exporter of DIN 2561 titanium flanges, meticulously engineered for performance in low-pressure piping systems. The DIN 2561 standard outlines specifications for weld neck flanges with a nominal pressure rating of PN6, but we also offer extended options including PN10, PN16, PN25, and PN40 based on customer requirements.

Our titanium flanges are crafted using premium-grade titanium alloys, ensuring exceptional corrosion resistance, lightweight strength, and reliability in critical environments such as chemical processing, marine systems, aerospace, and offshore operations.

Flange types:

• Weld neck flanges: Designed for high-integrity and stress-intensive piping systems

• Raised face (RF): Enhances gasket performance and leak-proof sealing

• Flat face (FF): Suitable where mating with brittle or non-metallic flange surfaces

Grades, chemical composition, and applications:

Titanium Grade 2 (UNS R50400) – Commercially Pure Titanium

Chemical composition:

Titanium (Ti): ≥ 98.90%

Iron (Fe): ≤ 0.30%

Oxygen (O): ≤ 0.25%

Carbon (C): ≤ 0.08%

Nitrogen (N): ≤ 0.03%

Hydrogen (H): ≤ 0.015%

Applications: Ideal for chemical processing, desalination, marine applications, and medical equipment. Excellent resistance to seawater, chlorides, and oxidizing environments. Lightweight and biocompatible, widely used in offshore platforms, heat exchangers, and aerospace structures.

Titanium Grade 5 (Ti-6Al-4V, UNS R56400) – Titanium Alloy

Chemical composition:

Titanium (Ti): Balance

Aluminum (Al): 5.5 – 6.75%

Vanadium (V): 3.5 – 4.5%

Iron (Fe): ≤ 0.40%

Oxygen (O): ≤ 0.20%

Carbon (C): ≤ 0.08%

Nitrogen (N): ≤ 0.05%

Hydrogen (H): ≤ 0.015%

Applications: Common in high-performance and structural applications including aerospace, automotive, and deep-sea systems. High strength-to-weight ratio, excellent corrosion resistance, and thermal stability make it ideal for demanding engineering environments.

Applications of DIN 2561 Titanium Flanges:

Marine & Offshore Industries: titanium flanges ideal for offshore drilling rigs, subsea equipment, and desalination plants, ensuring reliable performance in marine environments.

Chemical Processing: The superior corrosion resistance of titanium in aggressive chemicals makes it an excellent choice for reactors, pressure vessels, and pipelines used in chemical processing plants.

Aerospace & Aviation: Titanium is used in aerospace applications due to its lightweight, high strength, and ability to withstand extreme temperatures. .

Power Generation: In nuclear and thermal power plants, where materials must withstand high temperatures and corrosive conditions.

Key features:

• Manufactured as per DIN 2561 standard

• High dimensional accuracy and surface finish

• Custom sizes, face types, and drilling options available

Conclusion:

DIN 2561 titanium flanges from Ladhani Metal Corporation offer reliable, long-lasting performance in aggressive and weight-sensitive environments. With availability in grades like Titanium Grade 2 and Grade 5, these flanges meet international standards and suit a wide range of industrial applications. Our commitment to quality, precision, and customer satisfaction makes our titanium flanges a preferred choice across global industries. For technical details, pricing, or bulk inquiries, contact Ladhani Metal Corporation.

Send Message