Inconel Flanges

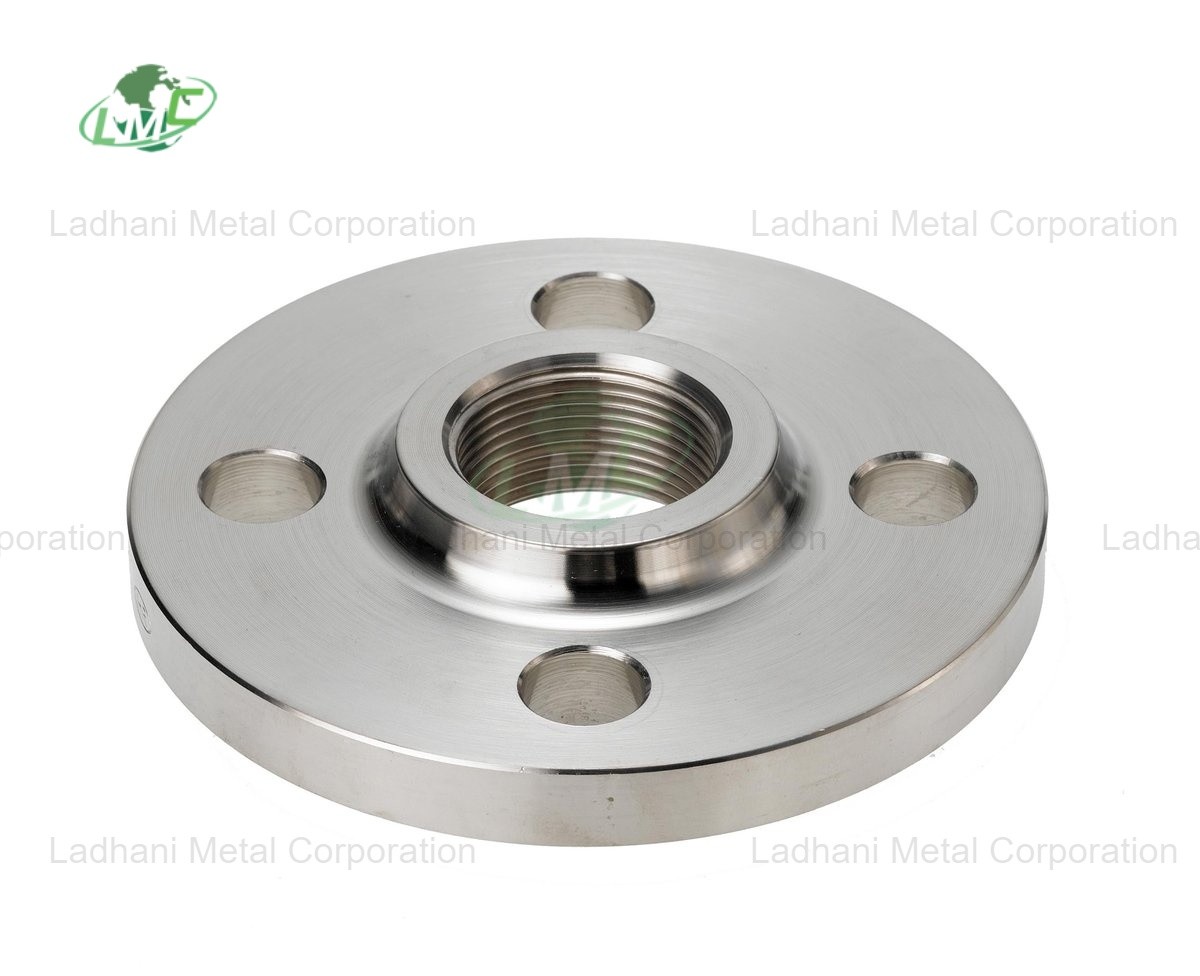

DIN 2568 Inconel Flanges PN 64 are precision-engineered threaded flanges made from high-strength Inconel alloys, designed for reliable operation in high-pressure, high-temperature, and corrosive environments. Manufactured in accordance with DIN 2568 standards, these flanges are ideal for use in critical industries such as aerospace, chemical processing, marine, nuclear, and high-temperature power generation, where resistance to oxidation, corrosion, and thermal fatigue is essential.

Ladhani Metal Corporation is a trusted manufacturer and exporter of Inconel flanges, offering components that adhere to the highest international quality and dimensional standards. The threaded design allows for quick, weld-free installation and removal, making these flanges highly suitable for systems requiring regular maintenance or disassembly.

Pressure Rating:

• PN 64 (64 bar / 928 psi): Engineered for high-pressure applications where material performance under extreme conditions is crucial.

Flange Types:

• Threaded (Screwed) Flanges

Provide efficient, weld-free assembly, ideal for pressure systems requiring ease of maintenance.

• Raised Face (RF) Flanges

Enhance sealing under high pressure and temperature using focused gasket compression.

• Flat Face (FF) Flanges

Used for even surface contact with flat-faced components, particularly when working with brittle or non-metallic materials.

• Forged Threaded Flanges

Offer improved mechanical strength, resistance to thermal fatigue, and precise dimensional control.

• Custom-Machined Flanges

Available in various Inconel grades, dimensions, and configurations as per project requirements.

Available Inconel Grades and Composition:

1. Inconel 600 (UNS N06600)

• Nickel (Ni): ≥ 72.0%

• Chromium (Cr): 14.0 – 17.0%

• Iron (Fe): 6.0 – 10.0%

Applications:

Used in chemical processing, heat-treating equipment, and nuclear reactors due to its excellent resistance to oxidation and carburization at elevated temperatures.

2. Inconel 625 (UNS N06625)

• Nickel (Ni): ≥ 58.0%

• Chromium (Cr): 20.0 – 23.0%

• Molybdenum (Mo): 8.0 – 10.0%

• Niobium (Nb): 3.15 – 4.15%

Applications:

Suitable for marine, aerospace, and chemical environments where superior strength, fatigue resistance, and protection from pitting and chloride-induced corrosion are required.

3. Inconel 718 (UNS N07718)

• Nickel (Ni): 50.0 – 55.0%

• Chromium (Cr): 17.0 – 21.0%

• Iron (Fe): Balance

• Niobium (Nb) + Tantalum (Ta): 4.75 – 5.50%

• Molybdenum (Mo): 2.80 – 3.30%

Applications:

Preferred for aerospace, high-speed turbines, and cryogenic systems due to its high tensile strength, creep resistance, and performance across a wide temperature range from cryogenic to over 700°C.

Applications of DIN 2568 Inconel Flanges:

• Aerospace and Jet Engine Components

Used in high-temperature exhaust, combustion, and structural parts.

• Chemical and Petrochemical Processing

Ideal for vessels, piping, and heat exchangers handling aggressive acids and solvents.

• Marine and Offshore Environments

Resistant to seawater corrosion and mechanical wear in subsea and shipboard systems.

• Nuclear and Power Generation

Suitable for steam generators, fuel handling systems, and reactor components.

• High-Temperature Industrial Systems

Used in furnace systems, heat-treatment fixtures, and thermal reactors.

Key Features:

• Conforms to DIN 2568 standard

• Rated for PN 64 high-pressure service

• Excellent resistance to corrosion, oxidation, and thermal fatigue

• High mechanical strength and performance across wide temperature ranges

• Threaded design enables non-welded, fast installation and disassembly

• Available with test certificates, MTCs, and full traceability

• Custom machining, surface treatment, and heat-resistance options available

Conclusion:

DIN 2568 Inconel Flanges PN 64 from Ladhani Metal Corporation are engineered for durability and precision in high-stress, high-temperature, and corrosive environments. Available in Inconel 600, 625, and 718, these flanges provide industry-leading strength, corrosion resistance, and reliability for the most critical applications. For tailored specifications, technical support, or consultation, contact Ladhani Metal Corporation today.

Send Message