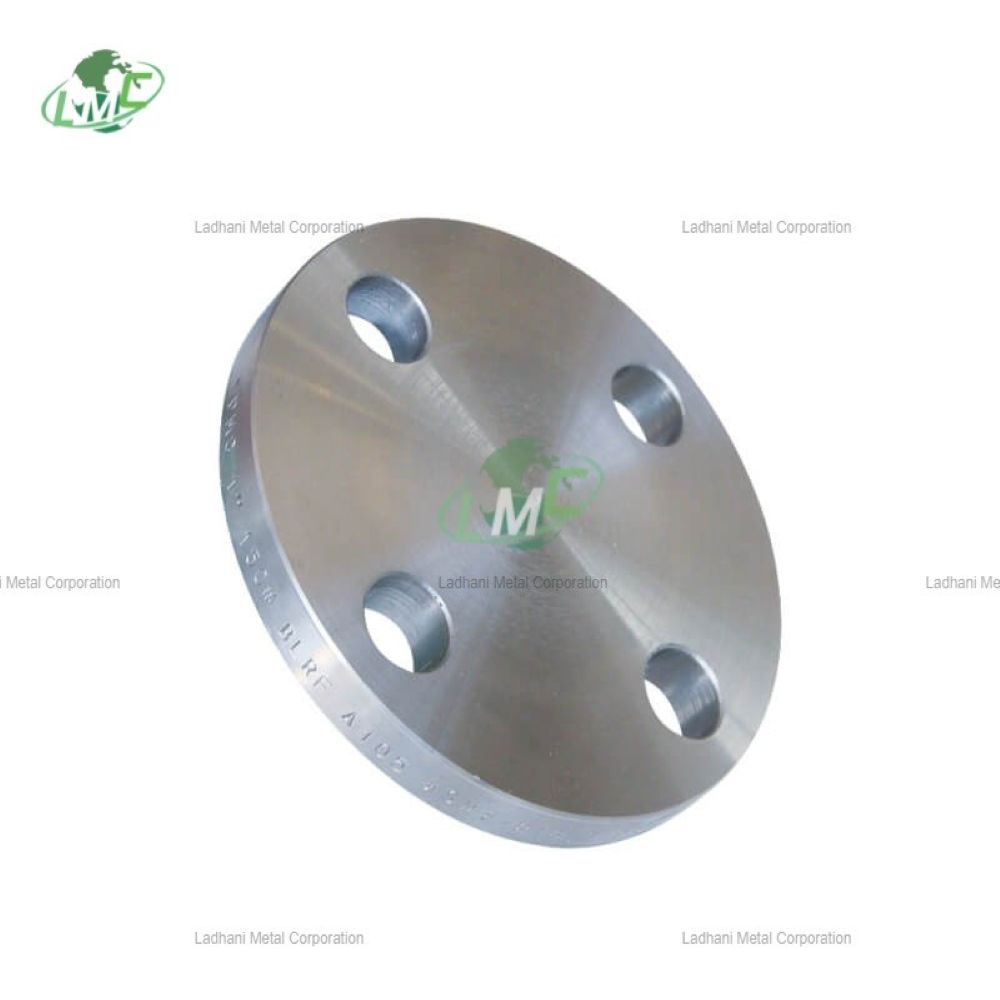

DIN 2627 Inconel flanges PN 400 are premium-grade blind flanges engineered for ultra-high-pressure applications requiring exceptional corrosion resistance, heat resistance, and mechanical strength. Manufactured in accordance with the DIN 2627 standard, these flanges are designed to seal off the ends of piping systems, especially in extreme environments involving high temperatures, aggressive chemicals, or seawater exposure. The PN 400 rating (400 bar / 5800 psi) ensures performance under intense pressure conditions. Produced using high-performance nickel-based alloys such as Inconel 600, Inconel 625, and Inconel 718, these flanges are used extensively in aerospace, chemical processing, offshore oil and gas, marine, and power generation industries. Ladhani Metal Corporation is a leading global manufacturer and exporter of Inconel flanges, supplying components that conform to international standards for material integrity, pressure containment, and corrosion resistance. Pressure Rating: • PN 400 (400 bar / 5800 psi): Suitable for high-pressure piping systems in critical applications where maximum sealing and durability are essential. Flange Type: • Blind Flanges Solid, non-bored flanges used to isolate piping systems or terminate flow. Ideal for pressure testing, maintenance, and future pipeline expansions. • Flat Face (FF) Flanges Designed with a flat sealing surface for use with full-face gaskets and flat mating components, ensuring even load distribution and effective sealing. Inconel Grades and Composition: Inconel 600 (UNS N06600) • Nickel (Ni): ≥ 72% • Chromium (Cr): 14 – 17% • Iron (Fe): 6 – 10% • Manganese (Mn): ≤ 1% • Silicon (Si): ≤ 0.5% • Carbon (C): ≤ 0.15% • Sulfur (S): ≤ 0.015% Applications: Excellent resistance to oxidation, carburization, and chloride-ion stress corrosion cracking. Used in furnace components, heat exchangers, and food processing equipment. Inconel 625 (UNS N06625) • Nickel (Ni): ≥ 58% • Chromium (Cr): 20 – 23% • Molybdenum (Mo): 8 – 10% • Niobium + Tantalum (Nb + Ta): 3.15 – 4.15% • Iron (Fe): ≤ 5% • Carbon (C): ≤ 0.10% • Manganese (Mn): ≤ 0.5% • Silicon (Si): ≤ 0.5% Applications: Outstanding corrosion and fatigue resistance in seawater and chemical environments. Common in marine, aerospace, and offshore industries. Inconel 718 (UNS N07718) • Nickel (Ni): 50 – 55% • Chromium (Cr): 17 – 21% • Iron (Fe): Balance • Niobium + Tantalum (Nb + Ta): 4.75 – 5.5% • Molybdenum (Mo): 2.8 – 3.3% • Titanium (Ti): 0.65 – 1.15% • Aluminum (Al): 0.2 – 0.8% Applications: High strength and oxidation resistance up to 700°C. Used in jet engines, gas turbines, and high-pressure valves. Applications of DIN 2627 Inconel Flanges PN 400: • Offshore Oil and Gas Platforms Withstands high-pressure, high-salinity, and corrosive environments in subsea pipelines and risers. • Chemical Processing Plants Ideal for systems handling oxidizers, acids, solvents, and reactive compounds at high temperatures and pressures. • Aerospace and Jet Propulsion Used in fuel systems, hydraulic lines, and turbine enclosures where extreme heat and stress are common. • Nuclear and Power Generation Suited for high-pressure reactor lines and heat exchanger systems exposed to radiation, heat, and corrosive media. • Desalination and Seawater Systems Highly resistant to chloride-induced pitting and crevice corrosion. • High-Temperature and Reactive Media Systems Perfect for isolating systems exposed to thermal cycling and chemical attack. Key Features: • Manufactured to DIN 2627 standards • Rated for PN 400 ultra-high-pressure systems • Blind flange design for sealing pipe ends or testing access • Flat face design for even gasket compression and sealing • Available in Inconel 600, 625, and 718 • Excellent resistance to oxidation, acids, chlorides, and high heat • High mechanical strength and fatigue resistance • Used in critical industries including aerospace, marine, oil and gas, and chemical processing • Custom sizes, alloys, pressure ratings, and surface finishes available on request Conclusion: DIN 2627 Inconel Flanges PN 400 from Ladhani Metal Corporation offer exceptional performance and reliability in the most demanding service conditions. Whether your system involves corrosive chemicals, high-pressure steam, or marine exposure, these blind flanges deliver secure sealing, longevity, and safety. Contact Ladhani Metal Corporation for material selection, technical support, or custom solutions tailored to your high-performance application.

Send Message