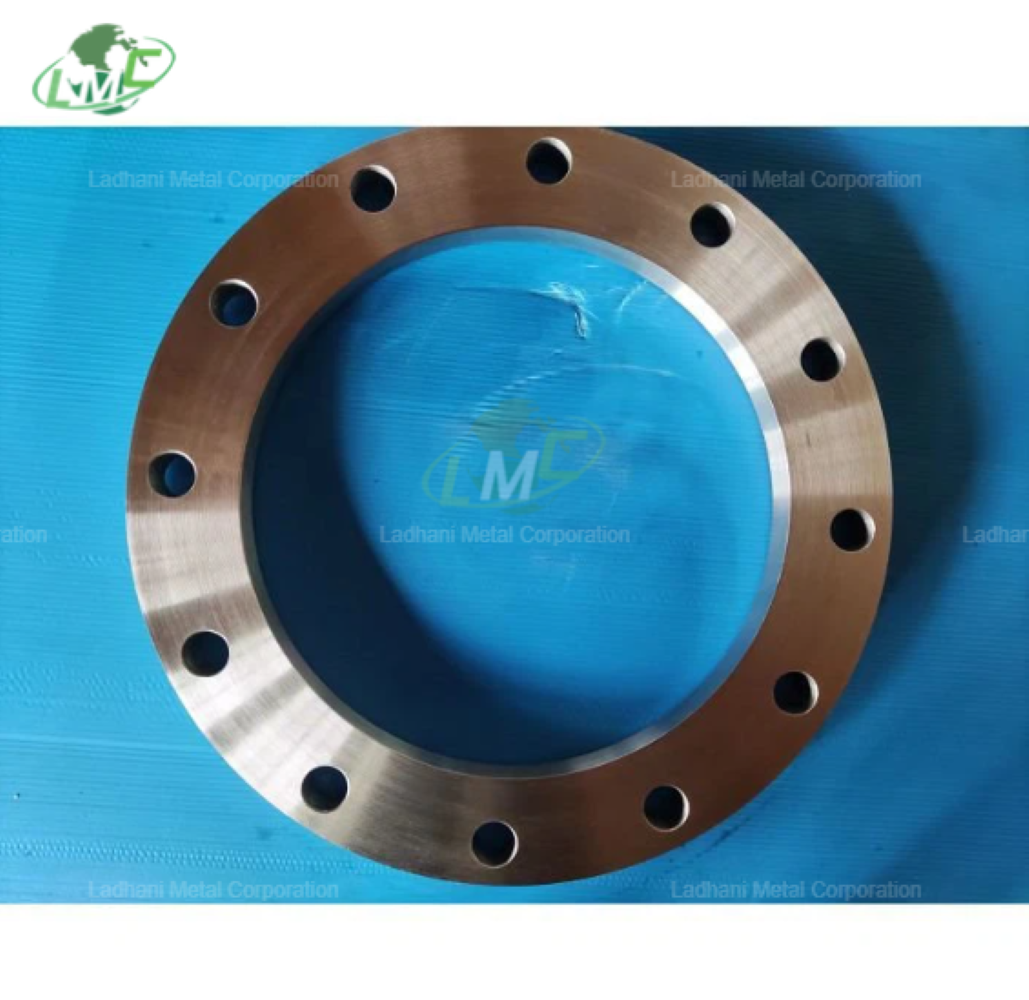

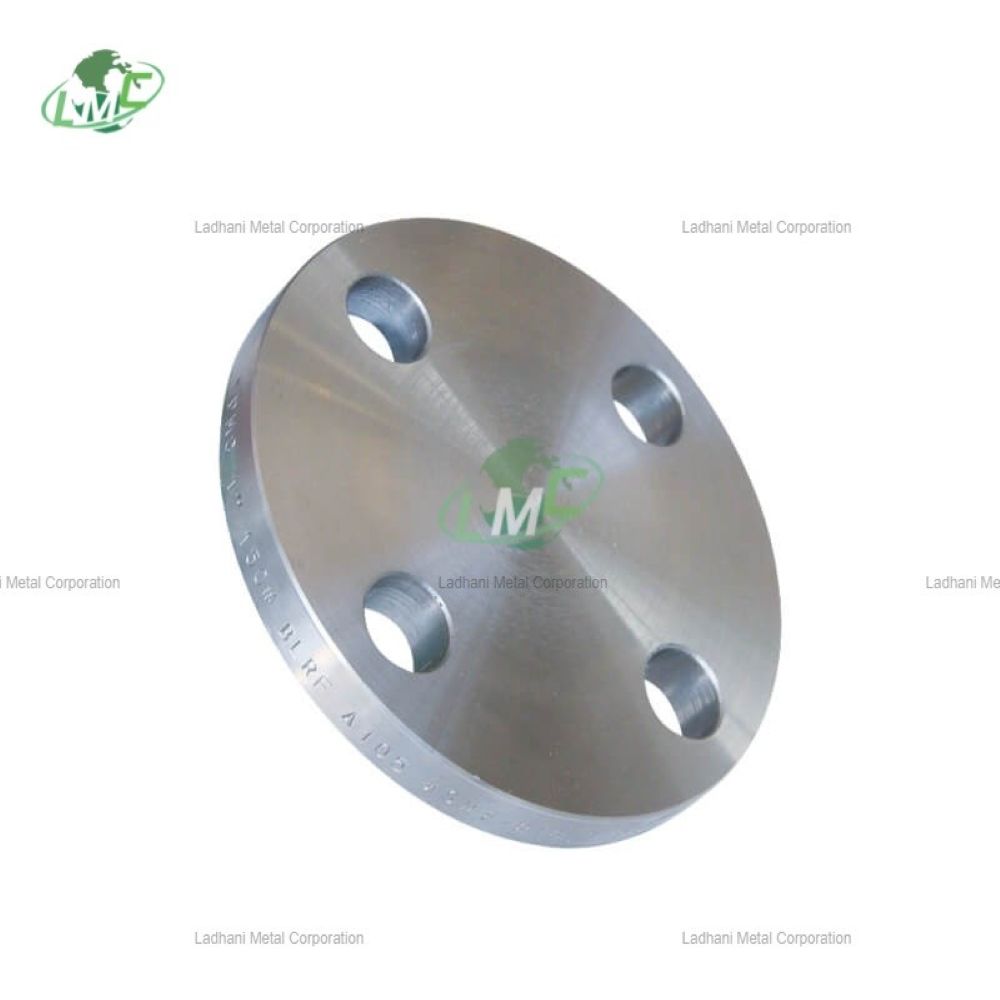

DIN 2634 monel flanges PN 25 are high-performance weld neck flanges manufactured in accordance with the DIN 2634 standard. Specifically engineered for high-pressure applications up to 25 bar (362 psi), these flanges are made from premium Monel alloys, offering excellent corrosion resistance, high strength, and durability in harsh environments. Their robust construction makes them ideal for applications involving aggressive chemical media and seawater where conventional metal flanges may degrade. Ladhani Metal Corporation is a trusted global manufacturer and supplier of Monel flanges, known for advanced manufacturing capabilities, precision machining, and strict adherence to international quality standards. Each flange undergoes thorough inspection and testing to ensure long-term reliability, safety, and resistance to extreme operating conditions. Pressure Rating: • PN 25 (25 bar / 362 psi): Designed for high-pressure systems requiring corrosion-resistant and mechanically robust flange connections. Flange Type: • Weld Neck Flanges Featuring an extended tapered hub, weld neck flanges provide excellent stress distribution at the base, ensuring strong and leak-proof joints in systems exposed to high pressure and thermal cycling. • Flat Face (FF) Flanges Ideal for use with softer gasket materials or in systems connecting to cast components, flat face flanges offer consistent and uniform gasket compression. Monel Grades and Typical Composition: Monel 400 (UNS N04400) – Nickel-Copper Alloy • Nickel (Ni): 63% minimum • Copper (Cu): 28-34% • Iron (Fe): 2.5% maximum • Manganese (Mn): 2.0% maximum • Carbon (C): 0.30% maximum Applications: Preferred in seawater and saltwater service, chemical processing, and marine equipment where excellent corrosion resistance in oxidizing and reducing environments is required. Monel K500 (UNS N05500) – Nickel-Copper Alloy with Additional Strengthening Elements • Nickel (Ni): 63% minimum • Copper (Cu): 28-34% • Iron (Fe): 2.5% maximum • Manganese (Mn): 2.0% maximum • Aluminum (Al) and Titanium (Ti): Added for age hardening Applications: Used in high-strength marine and chemical environments requiring enhanced mechanical properties and corrosion resistance. Applications of DIN 2634 Monel Flanges PN 25: • Offshore and Marine Systems Resists corrosion from seawater, brine, and marine atmospheres while maintaining strength under pressure. • Chemical and Petrochemical Processing Ideal for transporting corrosive media such as acids, alkalis, and chloride solutions at elevated pressures. • Desalination Plants Performs reliably in saltwater treatment and high-pressure water processing systems. • Power Generation Used in systems requiring resistance to erosion and corrosion in high-temperature steam and cooling circuits. • Pharmaceutical and Food Processing Applied in hygienic environments requiring corrosion resistance and chemical inertness. Key Features: • Manufactured in accordance with DIN 2634 dimensional and pressure requirements • PN 25 pressure rating supports high-pressure applications • Excellent resistance to corrosion, erosion, and stress corrosion cracking • Weld neck configuration ensures strong, vibration-resistant joints • Available in Monel 400 and Monel K500 alloys • Custom sizes, pressure classes, and surface finishes available upon request Conclusion: DIN 2634 monel flanges PN 25 from Ladhani Metal Corporation are engineered for demanding conditions where corrosion resistance, mechanical strength, and pressure integrity are essential. These Monel flanges provide long-term durability and reliable performance for advanced applications in marine, chemical, power generation, and industrial systems. For technical consultations, specialized requirements, or pricing information, contact Ladhani Metal Corporation today.