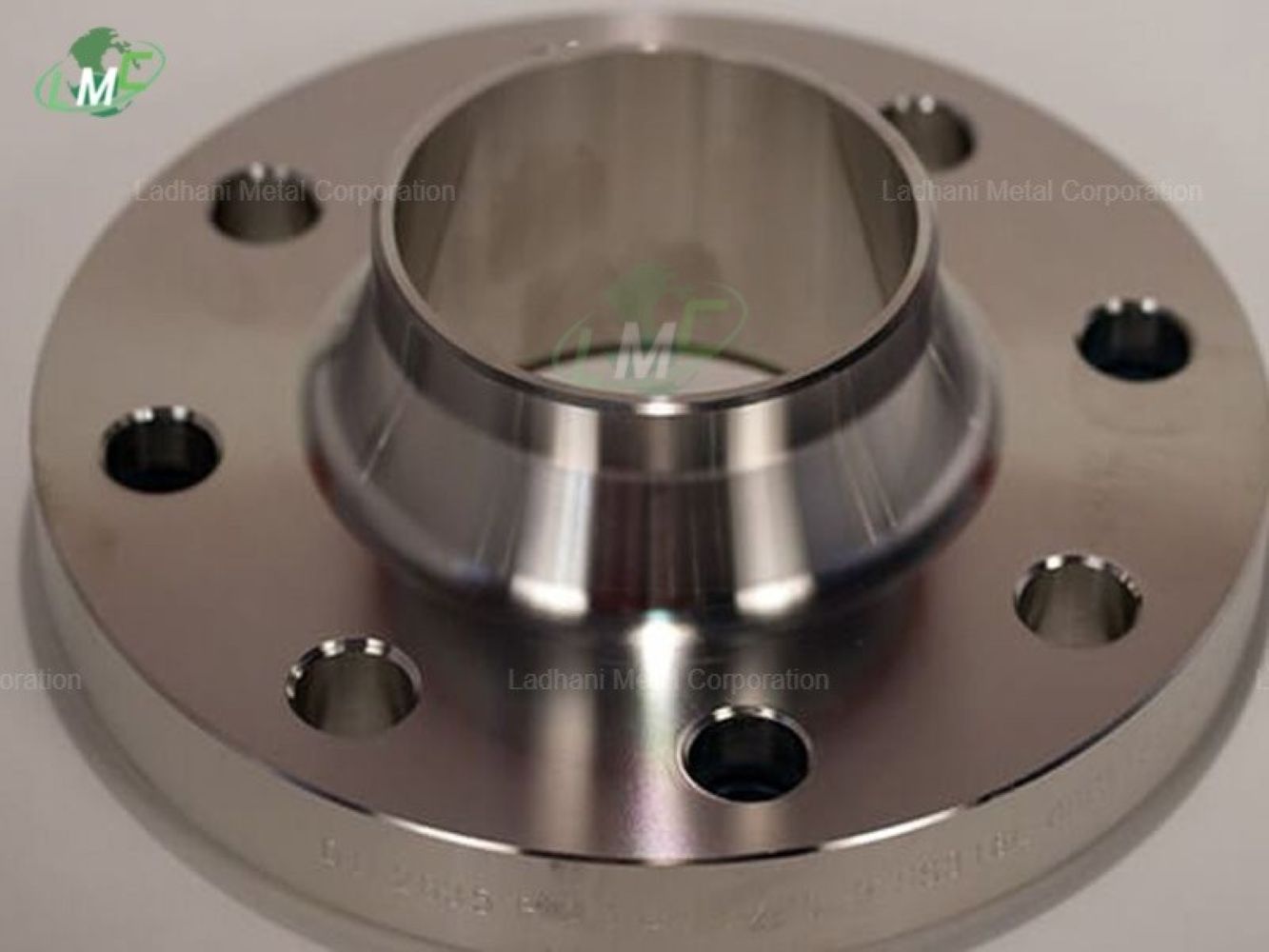

DIN 2633 Monel flanges PN 16 are precision-engineered weld neck flanges manufactured in accordance with the DIN 2633 standard. Designed for pipeline systems operating at pressures up to 16 bar (232 psi), these flanges provide exceptional resistance to corrosive environments, including seawater, acids, and alkalis. Manufactured from high-performance Monel alloys such as Monel 400 and Monel K500, they combine outstanding mechanical strength with excellent corrosion resistance, making them suitable for demanding industrial and marine applications. Ladhani Metal Corporation is a trusted global manufacturer and supplier of Monel flanges, known for superior material quality, dimensional accuracy, and strict compliance with international standards. Each flange undergoes rigorous quality checks and testing to ensure consistent performance in critical service conditions. Pressure Rating: • PN 16 (16 bar / 232 psi): Suitable for medium-pressure systems requiring corrosion resistance and structural reliability. Flange Type: • Weld Neck Flanges Designed with a long tapered hub to ensure smooth flow transitions, proper pipe alignment, and minimized stress concentration for high-integrity connections. • Flat Face (FF) Flanges Provides a uniform sealing surface ideal for systems with soft gasket materials or cast mating components, ensuring optimal gasket compression. Monel Grades and Full Composition: Monel 400 • Nickel (Ni): ≥ 63.0% • Copper (Cu): 28.0 – 34.0% • Iron (Fe): ≤ 2.5% • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 0.5% • Carbon (C): ≤ 0.3% Applications: Widely used in marine engineering, chemical processing, pump and valve components, and environments exposed to hydrofluoric and sulfuric acids. Monel K500 • Nickel (Ni): ≥ 63.0% • Copper (Cu): 27.0 – 33.0% • Aluminum (Al): 2.3 – 3.15% • Titanium (Ti): 0.35 – 0.85% • Iron (Fe): ≤ 2.0% • Carbon (C): ≤ 0.25% Applications: Suitable for high-strength applications in marine, oil and gas, and sour gas service environments. Offers improved mechanical properties over Monel 400 while retaining excellent corrosion resistance. Applications of DIN 2633 Monel Flanges PN 16: • Marine and Offshore Systems Ideal for saltwater piping, desalination systems, and submerged components due to excellent resistance to chloride stress corrosion. • Chemical Processing Industries Used in systems handling strong acids, alkalis, and organic solvents, especially hydrofluoric acid. • Oil and Gas Exploration Resistant to sour gas environments, high pressures, and corrosive drilling fluids. • Heat Exchangers and Condensers Monel flanges are preferred for their stability under fluctuating thermal loads and corrosive fluids. • Power Generation Used in cooling water and fuel handling systems where reliability under stress and corrosion is essential. Key Features: • Manufactured to DIN 2633 specifications • PN 16 rating for medium-pressure pipelines • Weld neck design for stress-distributed, leak-proof connections • Available in Monel 400 and K500 grades for tailored performance • Excellent resistance to corrosion in marine, acidic, and alkaline environments • High tensile strength and resistance to mechanical fatigue • Custom sizes, pressure classes, and finishes available on request Conclusion: DIN 2633 Monel Flanges PN 16 from Ladhani Metal Corporation offer robust performance in highly corrosive and pressure-sensitive applications. With superior resistance to seawater, acids, and harsh industrial chemicals, these flanges are engineered for longevity and strength in marine, chemical, and oil and gas systems. For custom configurations, technical advice, or pricing details, contact Ladhani Metal Corporation today.