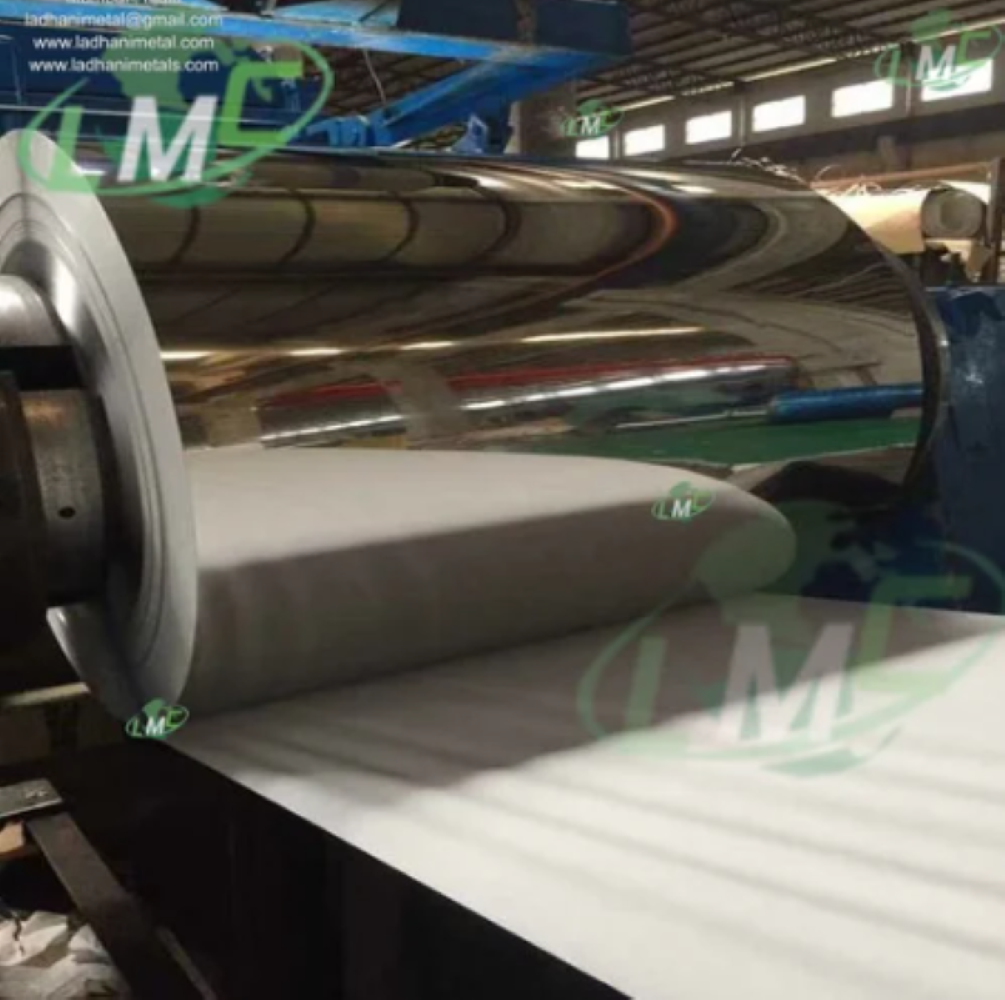

EN 10088 SS X2CrMoTi17-1 is a ferritic stainless steel containing approximately 17% chromium, 1% molybdenum, and titanium stabilization. The addition of molybdenum enhances resistance to pitting, crevice corrosion, and chloride-induced attack, while titanium improves weldability and prevents intergranular corrosion by stabilizing the carbon. This steel offers excellent corrosion resistance, good formability, and superior oxidation resistance, making it suitable for high-temperature and mildly aggressive environments. Ladhani Metal Corporation is a well-established manufacturer, supplier, and exporter of EN 10088 SS X2CrMoTi17-1 Strip, as well as Sheet, Plate, and Coil. Our stainless steel strips are available in various thicknesses, widths, and finishes such as 2B, BA, and No.4, catering to both industrial and decorative applications. Manufactured to international quality standards, these strips deliver durability, mechanical strength, and dimensional precision for diverse industries. Forms Available: strip, sheet, plate, coil Chemical Composition (%): • Carbon (C): ≤ 0.03 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 1.00 • Phosphorus (P): ≤ 0.040 • Sulphur (S): ≤ 0.015 • Chromium (Cr): 16.0 – 18.0 • Molybdenum (Mo): 0.80 – 1.20 • Titanium (Ti): ≥ 5 × C and ≤ 0.80 Mechanical Properties: • Tensile Strength: 430 – 650 MPa • Yield Strength (0.2% Proof): ≥ 250 MPa • Elongation: ≥ 20% • Hardness (HB): ≤ 200 Key Features: • Enhanced resistance to pitting and crevice corrosion due to molybdenum • Titanium stabilization improves weldability and structural stability • Excellent oxidation and scaling resistance up to 800°C • Magnetic structure with good mechanical strength • Smooth surface finish and easy formability Material Characteristics: EN 10088 SS X2CrMoTi17-1 Strip combines mechanical strength, corrosion resistance, and high-temperature stability. The molybdenum content provides superior protection in chloride-rich and mildly acidic environments, while titanium ensures structural integrity after welding. This material maintains dimensional stability, low thermal expansion, and consistent performance under cyclic heating conditions. Its balance of mechanical and corrosion-resistant properties makes it ideal for both functional and aesthetic applications. Applications: • Heat exchangers and condenser components • Automotive exhaust systems and trims • Chemical processing and marine equipment • Food processing and kitchen equipment • Architectural and industrial panels Conclusion: Ladhani Metal Corporation offers premium-quality EN 10088 SS X2CrMoTi17-1 Strip, Sheet, Plate, and Coil designed for long service life, superior corrosion resistance, and mechanical durability. Our products are manufactured with precision and adherence to international standards. For technical specifications, customized dimensions, or product-related inquiries, please contact Ladhani Metal Corporation – your reliable partner for stainless steel solutions. #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar #EN10088 #EN10088StainlessSteel #En10088SheetPlateCoilStrip #SSSheet #SSPlate #SSCoil #SSStrip #ColdRolledSteel #HotRolledSteel #CustomFabrication #CorrosionResistantSteel #DurableSteel #PrecisionEngineered #EN10088SSManufacturer #EN10088SSSupplier #EN10088SSExporter #ISOApproved #InternationalGradeSteel #HighPerformanceSteel #IndustrialSheet #IndustrialPlate #IndustrialCoil #IndustrialStrip #StainlessSteelSupplier #StainlessSteelManufacturer #StainlessSteelExporter #MetalFabrication #IndustrialApplications #ConstructionMaterials #EngineeringMaterials #OEMApplications #LadhaniMetals #MetalSupplier #MetalExporter #SteelIndustry #MarineSteelApplications #AutomotiveSteelApplications #ChemicalProcessingSteel #FoodProcessingSteel #PharmaGradeSteel #PowerGenerationSteel #HeatExchangerSteel #WaterTreatmentSteel #ArchitecturalSteel #IndustrialEquipmentSteel #CustomMetalSolutions #GlobalExporter #IndianManufacturer #TechnicalSpecifications #MaterialStandards #SteelFabricator #IndustrialSupplier #StainlessSteelIndia #StainlessSteelExporters #IndustrialMetals #MetalSheets #MetalPlates #MetalCoils #MetalStrips #SheetMetalProcessing #SteelFabrication #EngineeringProjects #OEMMetalSolutions #HighQualitySteel #LongLifeMaterial #FabricationMaterials #IndustrialSteel #StainlessSteelProducts