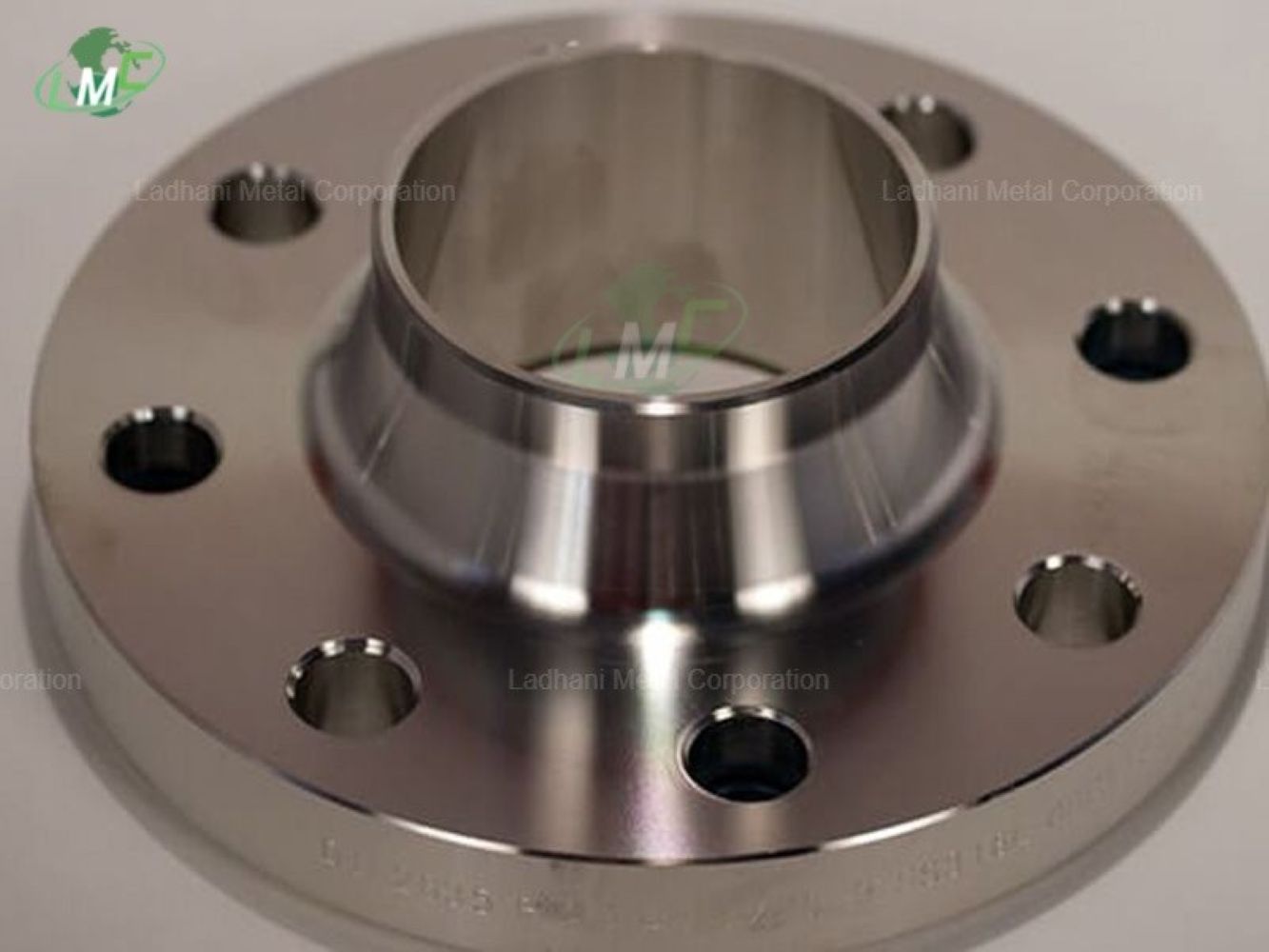

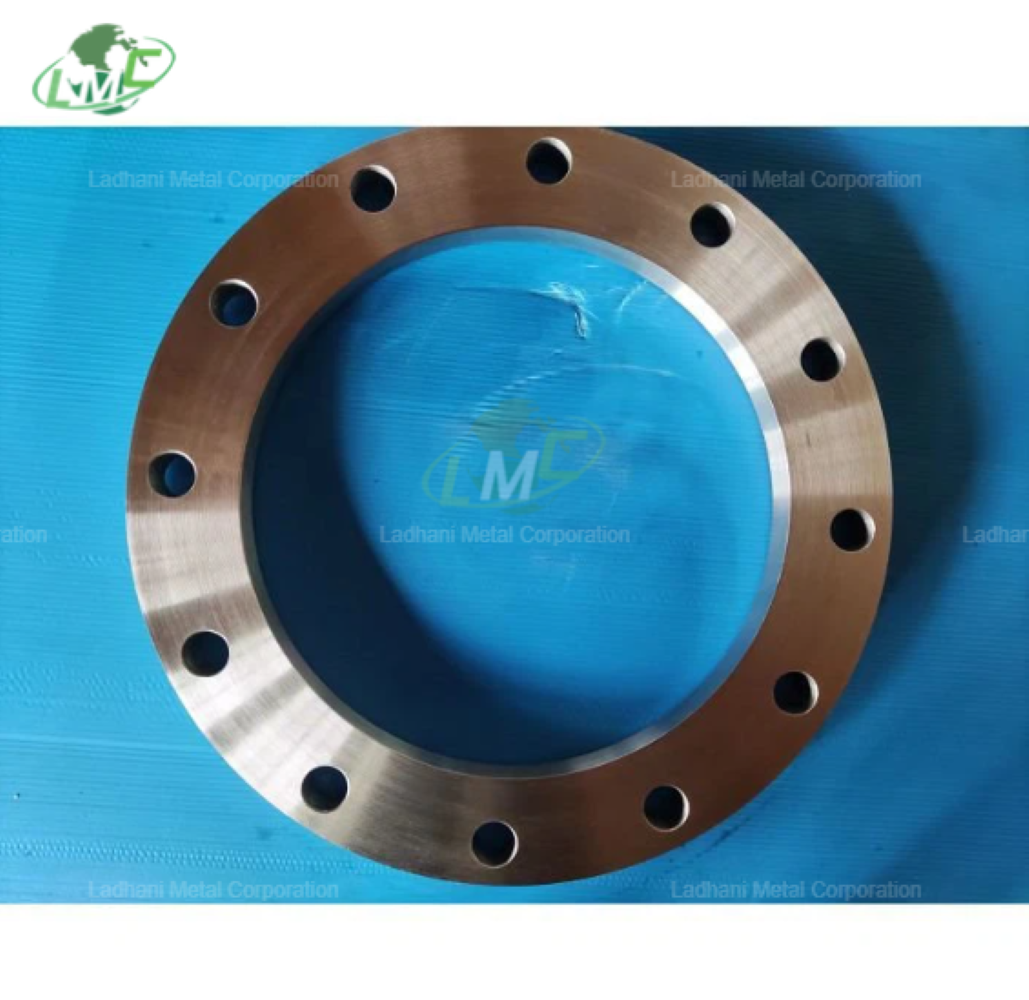

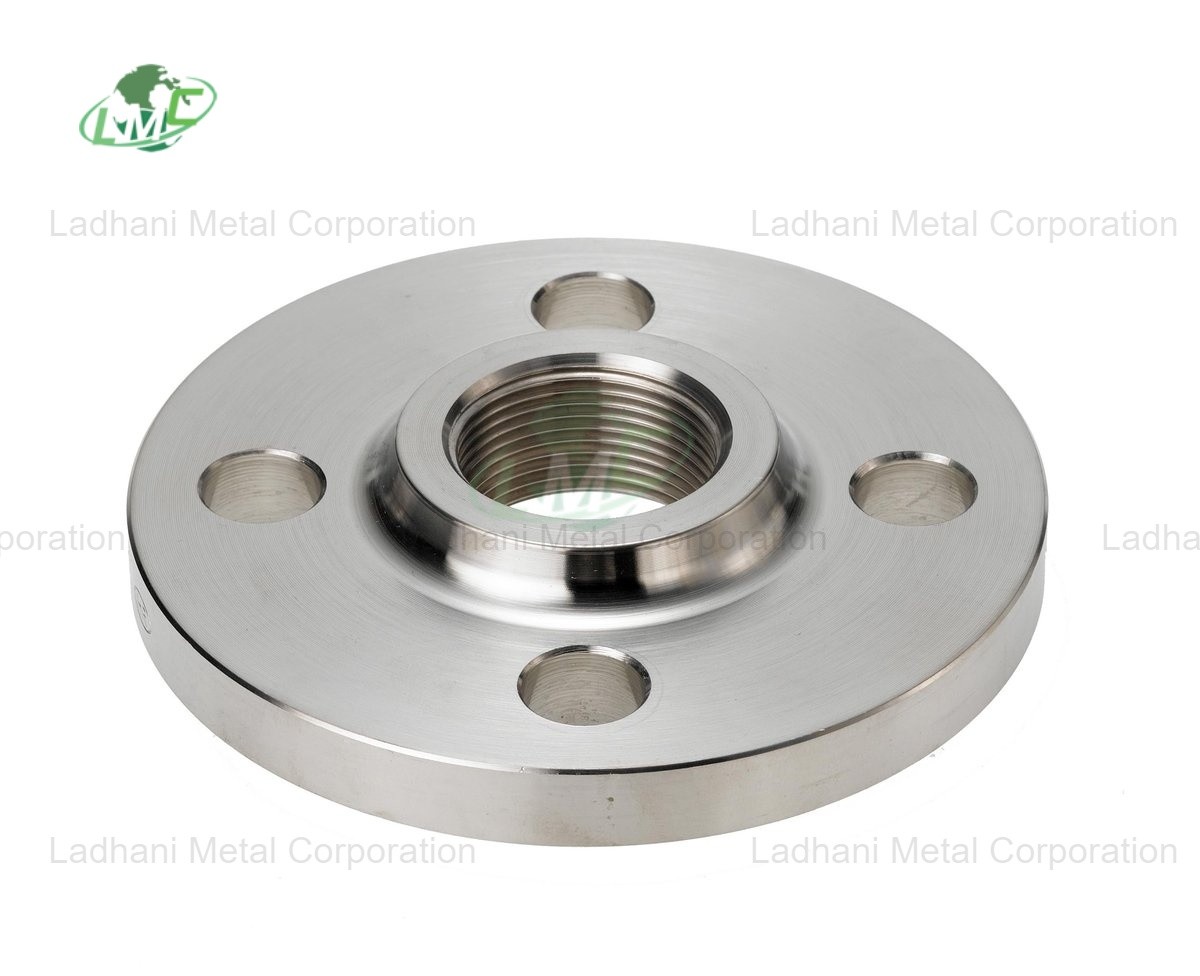

DIN 2628 Duplex steel flanges PN 250 are high-strength weld neck flanges designed according to the DIN 2628 standard for use in high-pressure systems up to 250 bar (3625 psi). Fabricated from Duplex stainless steels, these flanges offer an ideal balance of strength and corrosion resistance, combining the beneficial properties of both austenitic and ferritic stainless steels. Their robust mechanical performance, excellent resistance to stress corrosion cracking, and superior weldability make them well-suited for critical applications in aggressive service environments. Ladhani Metal Corporation manufactures and exports premium-grade Duplex steel flanges that meet stringent international standards for quality, reliability, and performance. Our DIN 2628 PN 250 Duplex steel weld neck flanges are widely used in sectors such as oil and gas, desalination, petrochemical processing, pulp and paper, and marine industries. With precision engineering and consistent quality, these flanges are designed to withstand high pressure, corrosive media, and mechanical stress. Pressure Rating: • PN 250 (250 bar / 3625 psi): Suitable for high-pressure systems requiring excellent structural integrity, corrosion resistance, and reliable sealing in dynamic conditions. Flange Type: • Weld Neck Flanges These flanges feature a tapered neck, offering high fatigue resistance by reducing stress concentration at the weld area. Ideal for applications with high pressure, high temperature, or repeated thermal cycling. • Flat Face (FF) Flanges Flat face design provides uniform gasket loading, minimizing the risk of flange deformation. Suitable for systems using brittle materials or low-pressure cast components. Duplex Steel Grades and Composition: Duplex 2205 (UNS S32205 / S31803) • Chromium (Cr): 21.0 – 23.0% • Nickel (Ni): 4.5 – 6.5% • Molybdenum (Mo): 2.5 – 3.5% • Nitrogen (N): 0.14 – 0.20% • Iron (Fe): Balance • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Carbon (C): ≤ 0.03% Applications: Offers excellent corrosion resistance, particularly to chloride-induced stress corrosion cracking and pitting. Commonly used in offshore oil rigs, chemical tanks, heat exchangers, and pressure vessels. Applications of DIN 2628 Duplex Steel Flanges PN 250: • Oil and Gas Exploration Resistant to sour gas, chloride attack, and high mechanical loads in subsea and topside environments. • Chemical Processing Plants Used in aggressive chemical systems, reactors, and storage vessels requiring high corrosion resistance. • Marine and Offshore Structures Reliable in saltwater applications, such as ballast systems, risers, and flowlines. • Pulp and Paper Industry Withstands acidic and alkaline process chemicals used in bleaching and pulping operations. • Water Treatment and Desalination Ideal for handling brine and high-chloride content fluids in RO and thermal desalination systems. Key Features: • Conforms to DIN 2628 standards • PN 250 pressure rating for high-pressure, heavy-duty systems • Weld neck configuration for excellent mechanical support and minimal stress concentration • Flat face variant ensures even gasket loading and leak-proof operation • Available in Duplex 2205 and Super Duplex 2507 grades • Excellent resistance to chloride stress corrosion, pitting, and crevice corrosion • High tensile and yield strength for demanding industrial conditions • Custom sizes, pressure ratings, and surface finishes available upon request Conclusion: DIN 2628 Duplex Steel Flanges PN 250 from Ladhani Metal Corporation are the optimal solution for applications requiring superior corrosion resistance, high mechanical strength, and reliable sealing performance under extreme pressure. Available in Duplex 2205 and Super Duplex 2507, these flanges offer outstanding performance across various aggressive industrial environments. For detailed technical specifications or to request a customized quotation, please contact Ladhani Metal Corporation.

Send Message