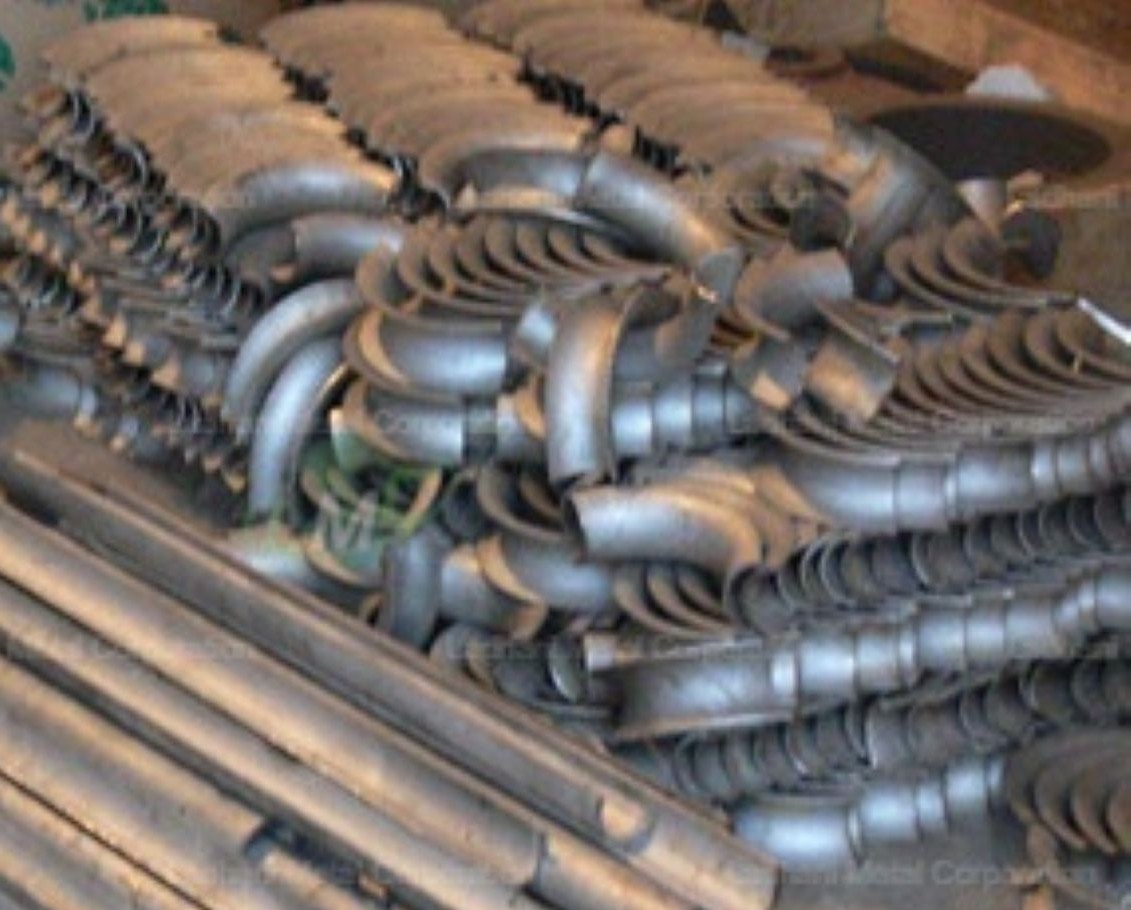

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are engineered to protect boiler and heat exchanger tubes from surface erosion, slag deposition, scaling, and mechanical damage in high-temperature operating conditions. These shields are widely used in power plants, thermal processing units, and industrial boilers where tube surfaces face direct exposure to flue gases and abrasive particles. The half-round structure allows for easy installation over curved or straight sections, providing long-term tube protection and reducing unplanned maintenance. 1Cr13 U Type Outer Half Round Tube Shield The 1Cr13 U Type Outer Half Round Tube Shield is manufactured from 1Cr13, a martensitic stainless steel with good hardness, moderate corrosion resistance, and excellent resistance to high-temperature oxidation. This outer U-type configuration is designed to shield the outer arc of U-bend tubes where erosion, scaling, and heat-induced wear are most intense. With its balance of strength and heat resistance, 1Cr13 is suitable for service in moderately corrosive environments involving flue gas exposure and mechanical impact. • Outer U Type Half Round Tube Shield – Covers the outer curve of U-bend tubes, providing a protective barrier against gas erosion, flame impingement, and slag buildup. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of 1Cr13 U Type Outer Half Round Tube Shields, offering reliable protection for industrial systems operating under high thermal and abrasive conditions. Chemical Composition of 1Cr13 – Martensitic Stainless Steel • Carbon (C): ≤ 0.15% • Manganese (Mn): ≤ 1.00% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 12.0 – 14.0% • Iron (Fe): Balance Applications: Suitable for applications with moderate corrosion exposure and high thermal and mechanical stress, including utility boilers, heat exchangers, and furnace systems. Uses • Protection of U-bend outer arcs in superheaters and reheaters in power and utility boilers • Shielding external tube curves in economizers, waste heat recovery units, and HRSGs • Coverage for return bends in industrial exhaust systems and flue gas ducts • Ideal for process heaters, furnace tubes, and high-temperature steam lines exposed to soot, slag, and scale • Suitable for systems requiring mechanical protection and moderate corrosion resistance Features • Good mechanical strength – Martensitic structure provides resistance to wear, abrasion, and high-velocity gas flow • Moderate corrosion resistance – Chromium content offers basic protection in mildly corrosive or oxidizing environments • Thermal stability – Maintains structural integrity in high-temperature zones with consistent exposure to flue gases • Outer arc protection – Specifically designed to guard the most exposed surface of U-bend tubes • Custom fit – Manufactured to match specific tube diameters and bend radii for precise, secure installation • Easy to install – Fastened using clamps, stainless bands, or tack welds without disrupting system operation • Economical and durable – Offers a cost-effective solution for extending tube service life under moderate conditions Applications • power plants – Used on U-bend outer arcs in superheaters and economizers to resist scaling and erosion • chemical and refining industries – Shields outer tube curves in process heaters exposed to heat and mechanical wear • waste heat recovery systems – Protects U-bend surfaces from slag and particulate impact in WHRBs and HRSGs • general industrial boilers – Provides protection in high-heat flue gas paths with minimal chloride exposure • metallurgy and cement processing – Applied in return bends in heating systems exposed to high-temperature dust and gas streams Conclusion The 1Cr13 U Type Outer Half Round Tube Shield by Ladhani Metal Corporation—manufacturer, supplier, and exporter—is a robust and cost-effective solution for shielding U-bend tube outer surfaces in boilers, heat exchangers, and industrial furnace systems. With reliable mechanical strength, moderate corrosion resistance, and high-temperature performance, this shield is ideal for systems requiring durable protection in abrasive and thermally demanding conditions. For technical consultation, custom orders, or quotations, please contact Ladhani Metal Corporation.