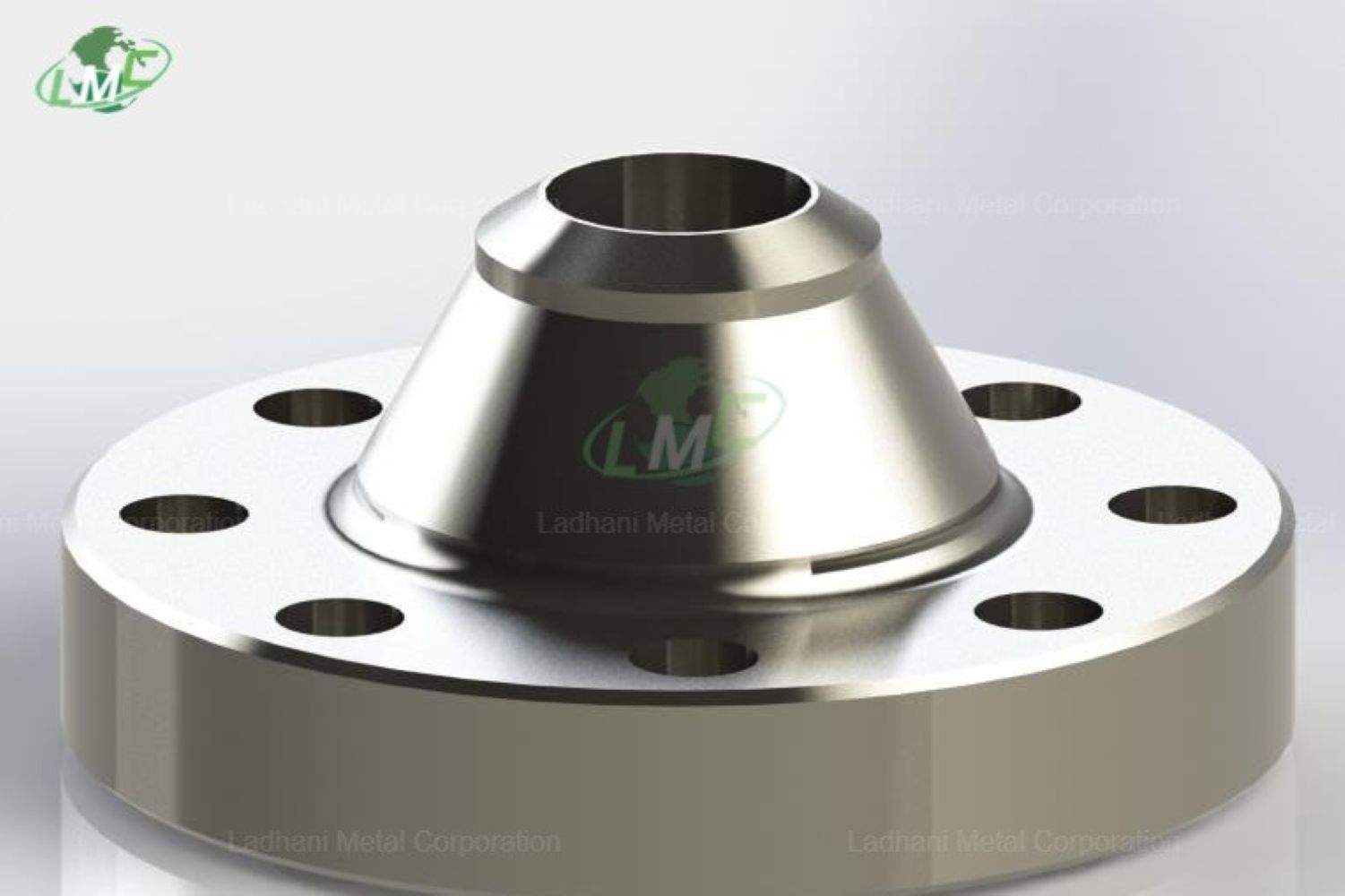

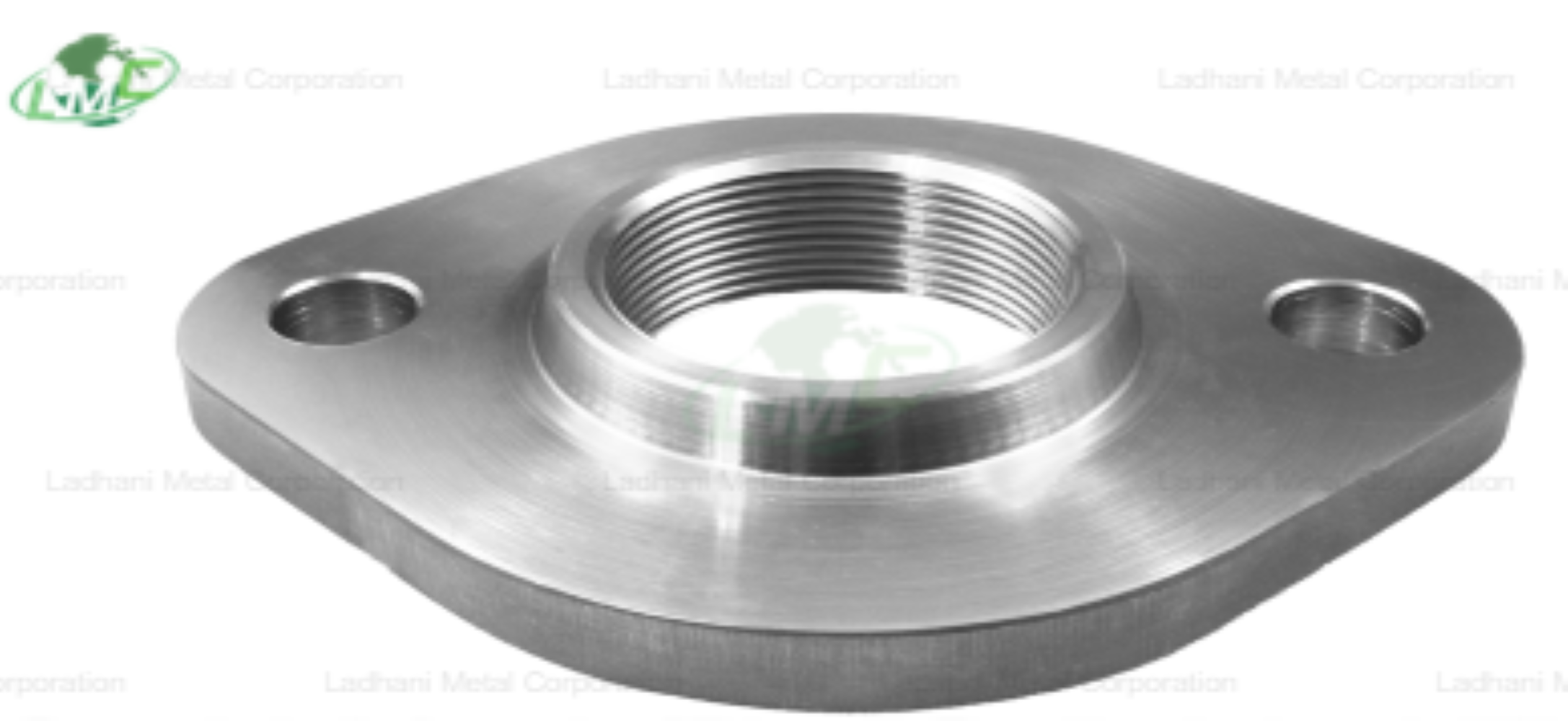

DIN 2633 titanium flanges PN 16 are precision-engineered weld neck flanges manufactured in accordance with the DIN 2633 standard. These flanges are designed for medium to high-pressure applications up to 16 bar (232 psi), delivering strong, lightweight, and corrosion-resistant connections in highly demanding pipeline environments. Constructed from premium-grade titanium alloys such as Grade 2 and Grade 5, they offer unmatched corrosion resistance, low density, and excellent mechanical properties, making them ideal for aggressive and weight-sensitive industrial applications. Ladhani Metal Corporation is a globally recognized manufacturer and supplier of titanium flanges, known for its technical expertise, product reliability, and adherence to stringent international specifications. Each flange undergoes meticulous quality checks to meet all applicable safety and performance standards. Pressure Rating: • PN 16 (16 bar / 232 psi): Designed for pipeline systems requiring secure, leak-free connections and outstanding corrosion protection under moderate pressure conditions. Flange Type: • Weld Neck Flanges Designed with an extended tapered hub to ensure superior structural support and reduce localized stress. Ideal for critical piping systems where fatigue resistance is essential. • Flat Face (FF) Flanges Provides an even sealing surface for use with softer gaskets or systems involving cast components, ensuring leak-proof performance and consistent compression. Titanium Grades and Full Composition: Titanium Grade 2 • Titanium (Ti): ≥ 98.8% • Iron (Fe): ≤ 0.30% • Oxygen (O): ≤ 0.25% • Carbon (C): ≤ 0.08% • Nitrogen (N): ≤ 0.03% • Hydrogen (H): ≤ 0.015% Applications: Preferred in desalination, chemical processing, marine, and medical applications due to its excellent corrosion resistance and biocompatibility. Titanium Grade 5 (Ti-6Al-4V) • Titanium (Ti): Balance • Aluminum (Al): 5.5 – 6.75% • Vanadium (V): 3.5 – 4.5% • Iron (Fe): ≤ 0.40% • Oxygen (O): ≤ 0.20% • Carbon (C): ≤ 0.08% • Nitrogen (N): ≤ 0.05% • Hydrogen (H): ≤ 0.015% Applications: Commonly used in aerospace, offshore, automotive, and industrial systems requiring high strength-to-weight ratio, fatigue resistance, and temperature stability. Applications of DIN 2633 Titanium Flanges PN 16: • Desalination Plants Highly resistant to seawater and chlorides, suitable for intake and discharge piping. • Chemical and Pharmaceutical Industries Used in handling reactive or highly corrosive media where stainless steel may fail. • Aerospace and Defense Ideal for weight-sensitive applications requiring structural integrity and resistance to atmospheric conditions. • Oil and Gas Reliable in offshore platforms and downhole equipment exposed to saltwater and high pressures. • Medical Equipment Manufacturing Biocompatible properties allow safe usage in hygienic and sterile processing systems. Key Features: • Precision manufactured to DIN 2633 specifications • PN 16 pressure rating for medium to high-pressure performance • Weld neck flange design ensures enhanced mechanical stability • Available in corrosion-resistant titanium grades 2 and 5 • Lightweight construction reduces overall system load • High resistance to acids, chlorides, and extreme environments • Custom dimensions, pressure classes, and finishes available on request Conclusion: DIN 2633 Titanium Flanges PN 16 from Ladhani Metal Corporation provide a high-performance solution for systems that require excellent corrosion resistance, mechanical strength, and reduced weight. With superior manufacturing precision and quality assurance, these flanges are suited for challenging environments in marine, aerospace, chemical, and medical sectors. For custom specifications, detailed technical assistance, or pricing inquiries, contact Ladhani Metal Corporation today.

Send Message