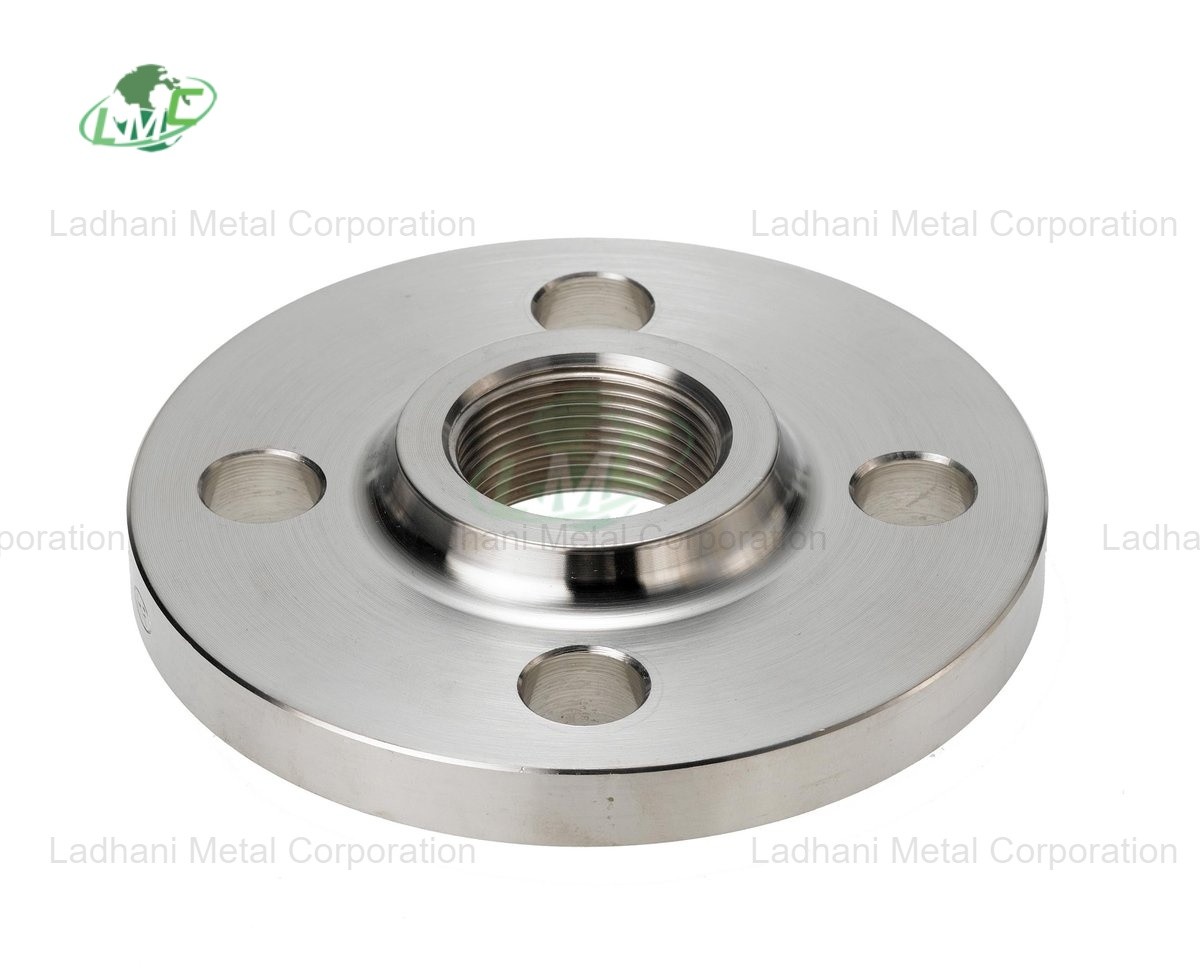

DIN 2543 Stainless Steel Flanges are flanges made from stainless steel that conform to the German industrial standard DIN 2543. These flanges are used to connect pipes, valves, pumps, and other equipment within a piping system. The DIN 2543 standard defines the specifications, dimensions, and materials for flanges used primarily in industrial applications where high strength, durability, and corrosion resistance are required. DIN 2543 refers to the "Flanges for pipes, slip-on flanges, welding neck flanges, and blind flanges." DIN 2543 flanges are PN 16, and they have specific dimensional standards for that pressure rating, ensuring compatibility and safety in pipeline applications. Here's a detailed description of DIN 2543 Stainless Steel Flanges: 1. Standard Overview (DIN 2543): • DIN 2543 refers to flanges that are used to connect pipes and related components in various industrial systems. It specifies welding neck flanges, slip-on flanges, and blind flanges among others. • The flanges covered by this standard are available in different pressure classes and materials, including stainless steel. • The main application of these flanges is in piping systems for industries such as chemical, oil and gas, water treatment, food processing, and HVAC. 2. Types of DIN 2543 Flanges: The standard covers different types of flanges, each with its own application: • Welding Neck Flanges (WN): o These flanges are designed to be welded to the pipe. They have a long tapered neck that provides better stress distribution and is suitable for high-pressure applications. o Application: Common in high-pressure and high-temperature systems. • Slip-On Flanges (SO): o These flanges fit over the pipe and are welded at both the inside and outside edges. They are easier to install compared to welding neck flanges. o Application: Suitable for low- and medium-pressure systems. • Blind Flanges (BL): o These flanges are used to seal the end of a pipe. They have no central hole and are typically used to close off piping systems or for future extensions. o Application: Used when a permanent or temporary closure is needed in a piping system. 3. Materials for Stainless Steel Flanges: DIN 2543 Stainless Steel flanges are typically manufactured from the following grades of stainless steel, which are selected based on the specific requirements of the application: • Grade 304 Stainless Steel (AISI 304): o The most common type of stainless steel, offering good corrosion resistance and forming ability. It is suitable for general-purpose applications in environments not subject to severe corrosion. o Applications: Food and beverage processing, chemical industries, and general industrial applications. • Grade 316 Stainless Steel (AISI 316): o Contains molybdenum (2–3%), which significantly enhances its resistance to pitting and crevice corrosion in chloride environments. It is widely used in more corrosive environments such as marine or chemical processing applications. o Applications: Marine environments, chemical industries, pharmaceuticals, and offshore applications. • Grade 321 Stainless Steel (AISI 321): o Similar to 304 but with added titanium to prevent carbide precipitation during welding. It is ideal for high-temperature environments and offers good oxidation resistance. o Applications: High-temperature systems, aerospace applications, and heat exchangers. 4. Gasket Surface Types: The gasket surface of DIN 2543 stainless steel flanges is crucial for creating a proper seal when two flanges are joined. The most common gasket surface types include: • Raised Face (RF): o A flange with a raised area where the gasket is placed. This is the most common type and provides a reliable seal. • Flat Face (FF): o The flange surface is flat and typically used in lower-pressure systems. • Ring Type Joint (RTJ): o This type has a groove for the insertion of a metal ring gasket, used in high-pressure or high-temperature applications. DIN 2543 SS flanges are designed to provide strong, durable, and leak-proof connections for pipes in various industries, with precise dimensions, materials, and pressure ratings tailored to different operational needs. The different types of flanges (Slip-on, Welding Neck, and Blind) allow for versatile use in a variety of applications.

Send Message