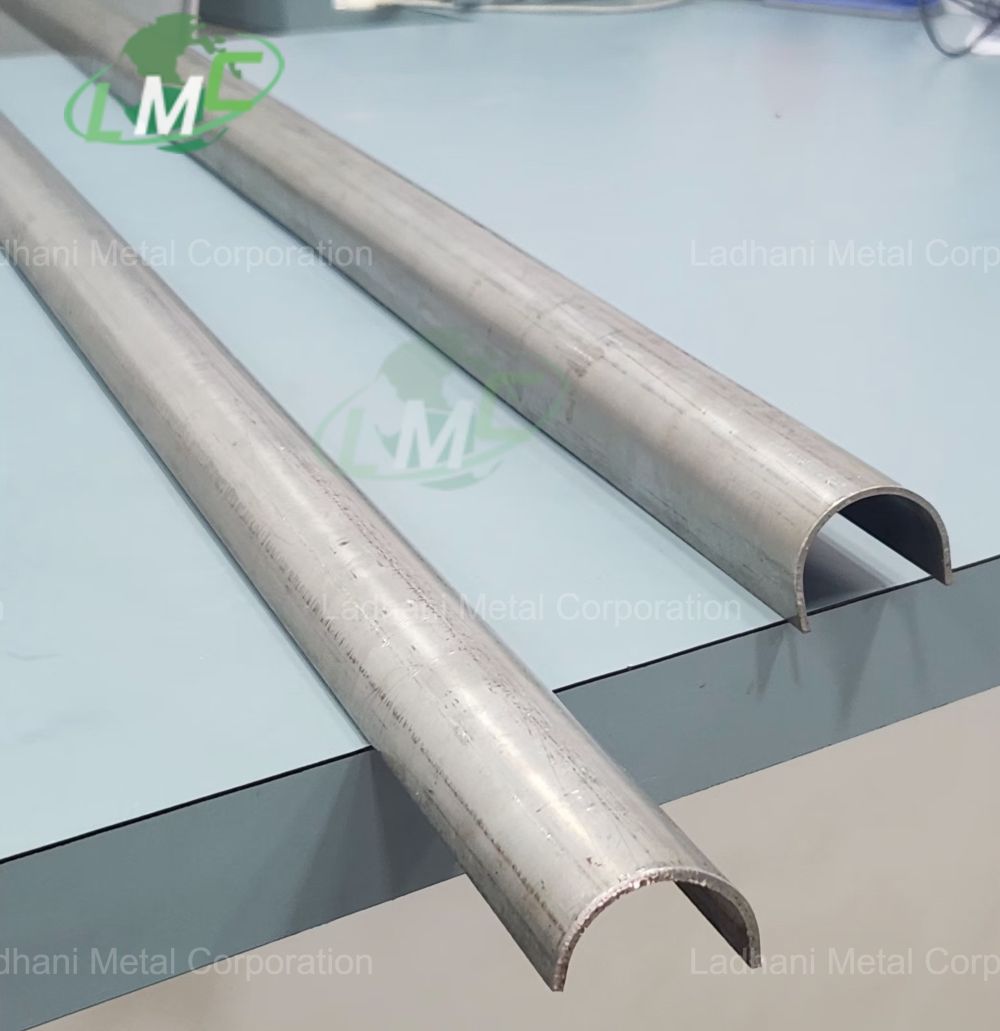

Product name: Gr1 Titanium seamless tube Standard:ASTM B338 Material:Grade 1 titanium Diameter:5-914mm Wall thickness:0.5-10mm Length:Max 16000mm Surface:Pickling surface/Polished Type:Seamless, welded Application:Heat Exchanger, chemical industry etc. Technique:Rolled Gr1 Titanium seamless tube The production process of titanium seamless pipe is complex. Three roll or multi roll rolling mill and drawing machine are usually used to roll or draw a certain specification of pipe blank through multiple passes, and finally produce seamless pipe after reducing diameter and wall. The production efficiency and yield of this process are low. Titanium seamless pipe from sponge titanium to pipe, through rolling or drawing, the material waste is large, the yield is only about 50%, and can not achieve mass production, and the production cycle is relatively long. Product name Titanium seamless tube Standard ASTM B861, ASTM B337, ASTM B338 Size OD5.0-114.0mmxWT0.5-7.0mmx1000-12000mm OD55mm-914mmxWT1.0-10.0mmx1000-6000mm Or according customer’s requirement. Material Titanium(Gr1, Gr2, Gr5, Gr7,Gr9,GR12) Technique Rolled Status Annealled Surface Acid wash,bright Application Exhaust pipe; exhaust pipe, petroleum pipeline;Sea farming; electroplating equipment;Fluid Transportation Piping etc. Certificate ISO9001:2008, TUV, EN10204.3.1 Types Out diameter Sizes Length NB Sizes (in stock) .0035” ~ 8” 1/8", 1/4", 3/8", 1/2", 5/8", 3/4", 1", 1.25", 1.5", 2", 2.5", 3", 4", 5", 6" Cut to length Titanium Seamless Tube (Custom Sizes) 6.35 mm OD To 101.6 mm OD As per requirement Cut to length Titanium seamless pipe features: 1. The thicker the wall thickness is, the more economical and practical it is. The thinner the wall thickness is, the higher its processing cost will be 2. The process of titanium seamless pipe determines its limited performance. Generally, the precision of seamless steel pipe is low, the wall thickness is uneven, the brightness of the inner and outer surface of the pipe is low, the sizing cost is high, and there are pockmarks and black spots on the inner and outer surface, which are not easy to remove 3. Its detection and shaping must be processed offline. Therefore, it embodies its advantages in high pressure, high strength and mechanical structure materials.