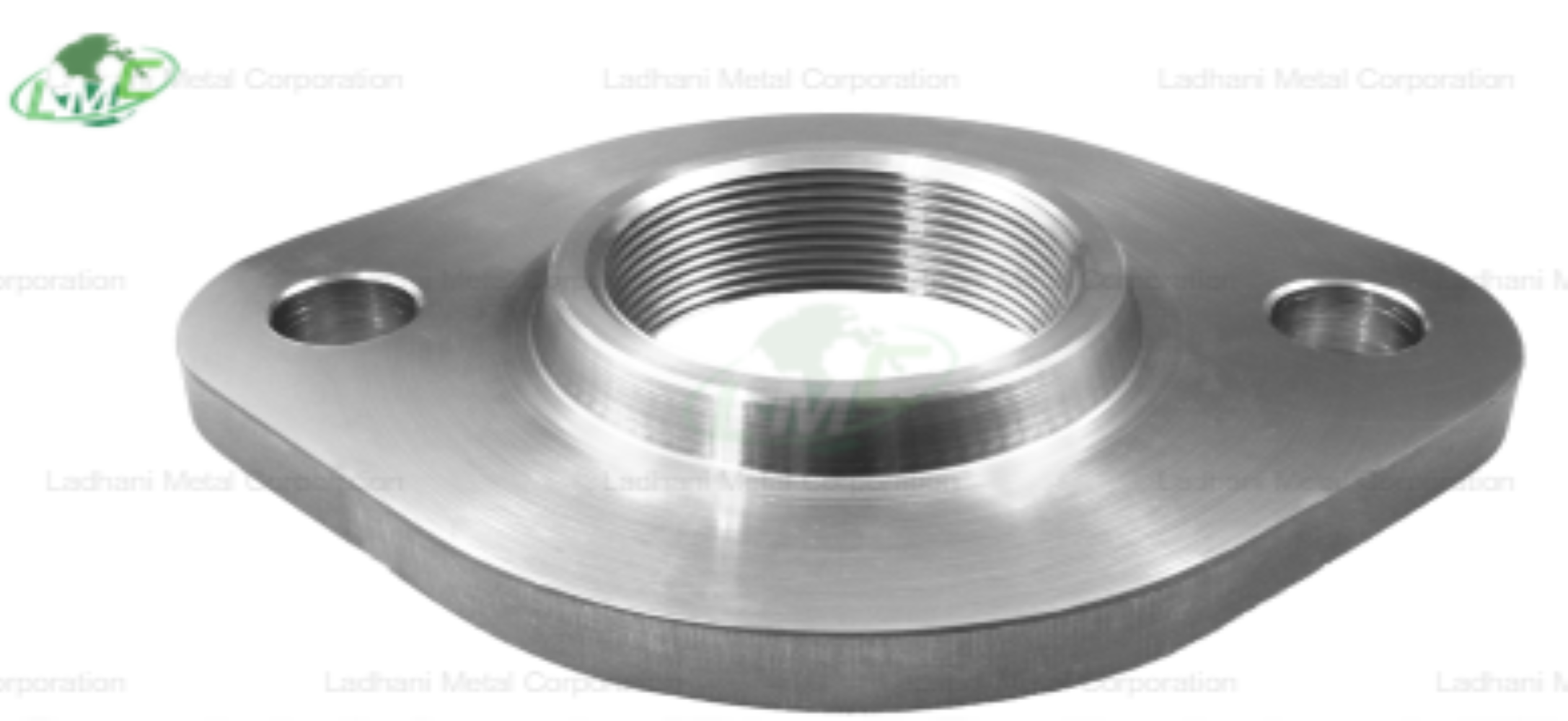

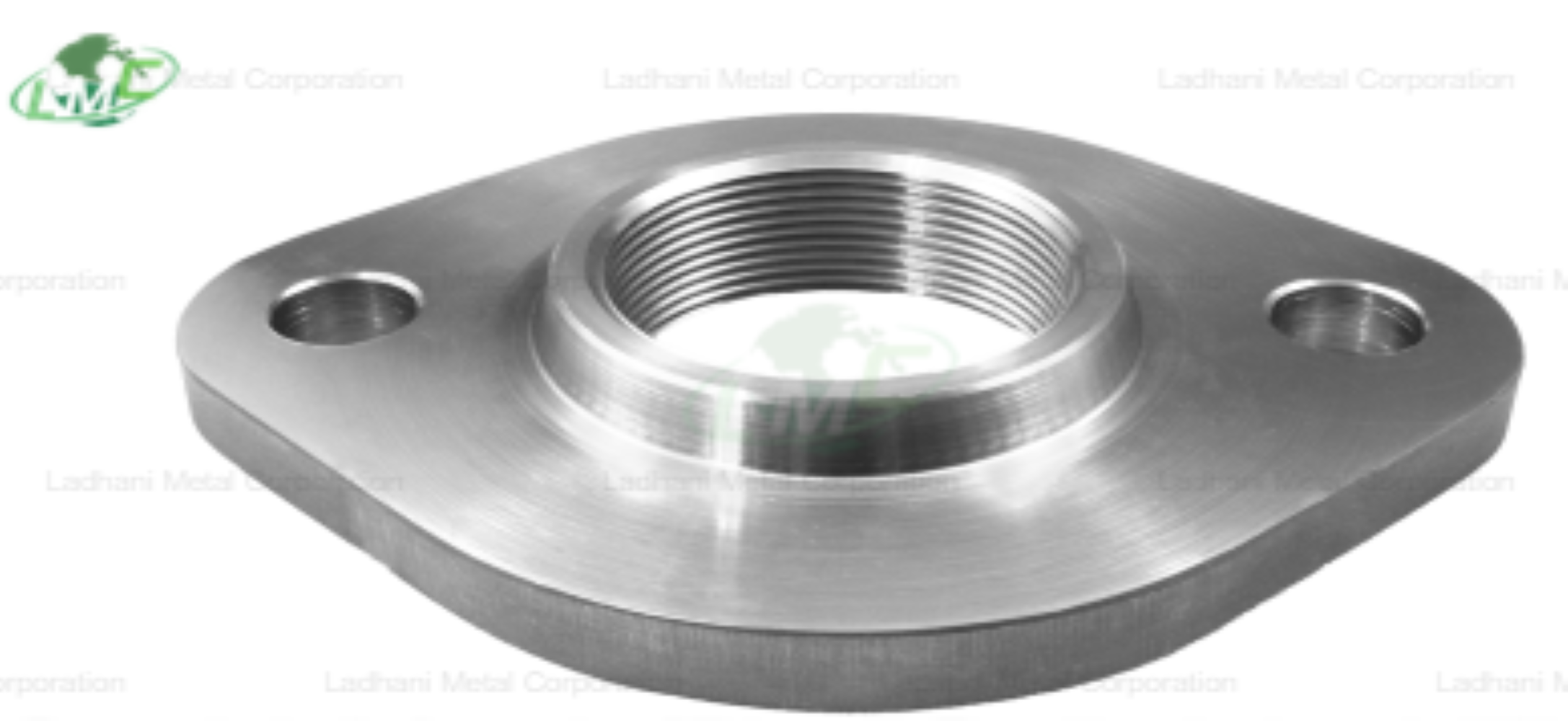

Ladhani Metal Corporation is a well-established manufacturer and exporter of DIN 2561 duplex flanges, specifically engineered for optimal performance in low-pressure piping systems. The DIN 2561 standard specifies weld neck flanges with a nominal pressure rating of PN6, and we offer extended pressure ratings including PN10, PN16, PN25, and PN40 based on customer specifications. Our duplex flanges are manufactured using duplex stainless steel, combining the best properties of both austenitic and ferritic steel. This unique composition ensures excellent corrosion resistance, high strength, and resistance to stress corrosion cracking in aggressive environments. These flanges are ideal for critical applications in industries such as chemical processing, petrochemical, marine, and offshore oil and gas sectors. Flange types: • Weld neck flanges: Suitable for high-integrity, high-stress piping systems • Raised face (RF): Designed to improve gasket performance and create leak-proof sealing • Flat face (FF): Ideal where mating surfaces are brittle or non-metallic Grades, chemical composition, and applications: Duplex Stainless Steel 2205 (UNS S32205) Chemical composition: Chromium (Cr): 22.0 – 23.0% Nickel (Ni): 4.5 – 6.0% Molybdenum (Mo): 3.0 – 3.5% Iron (Fe): Balance Manganese (Mn): ≤ 2.0% Silicon (Si): ≤ 1.0% Carbon (C): ≤ 0.03% Nitrogen (N): 0.14 – 0.2% Phosphorus (P): ≤ 0.035% Sulfur (S): ≤ 0.02% Applications: Duplex Stainless Steel 2205 is ideal for applications requiring high strength and excellent resistance to pitting and crevice corrosion, especially in environments with chloride exposure. Duplex Stainless Steel 2507 (UNS S32750) Chemical composition: Chromium (Cr): 24.0 – 26.0% Nickel (Ni): 6.0 – 8.0% Molybdenum (Mo): 3.0 – 5.0% Iron (Fe): Balance Manganese (Mn): ≤ 2.0% Silicon (Si): ≤ 1.0% Carbon (C): ≤ 0.03% Nitrogen (N): 0.24 – 0.32% Phosphorus (P): ≤ 0.03% Sulfur (S): ≤ 0.02% Applications: Duplex Stainless Steel 2507 is designed for extremely harsh environments requiring superior resistance to both chloride stress corrosion cracking and general corrosion. Key features: • Manufactured as per DIN 2561 standard • High dimensional accuracy and surface finish • Custom sizes, face types, and drilling options available Applications: • Marine & Offshore Industries: Duplex flanges, with their excellent resistance to corrosion and stress corrosion cracking, are ideal for use in seawater applications, including subsea pipelines, offshore platforms, and desalination plants. • Chemical Processing: Duplex flanges are well-suited for high-stress and corrosive chemical environments, making them ideal for reactors, pressure vessels, and piping systems in the chemical and petrochemical industries. • Oil & Gas: The high strength and corrosion resistance of duplex flanges make them perfect for demanding offshore and subsea applications, such as pipelines, manifolds, and risers. DIN 2561 duplex flanges from Ladhani Metal Corporation are an ideal choice for industries requiring superior performance, resistance to corrosion, and high strength in challenging environments. Meeting international standards and manufactured with precision, our duplex flanges are the preferred solution for a wide range of applications in various sectors. For technical details, pricing, or bulk inquiries, contact Ladhani Metal Corporation.

Send Message