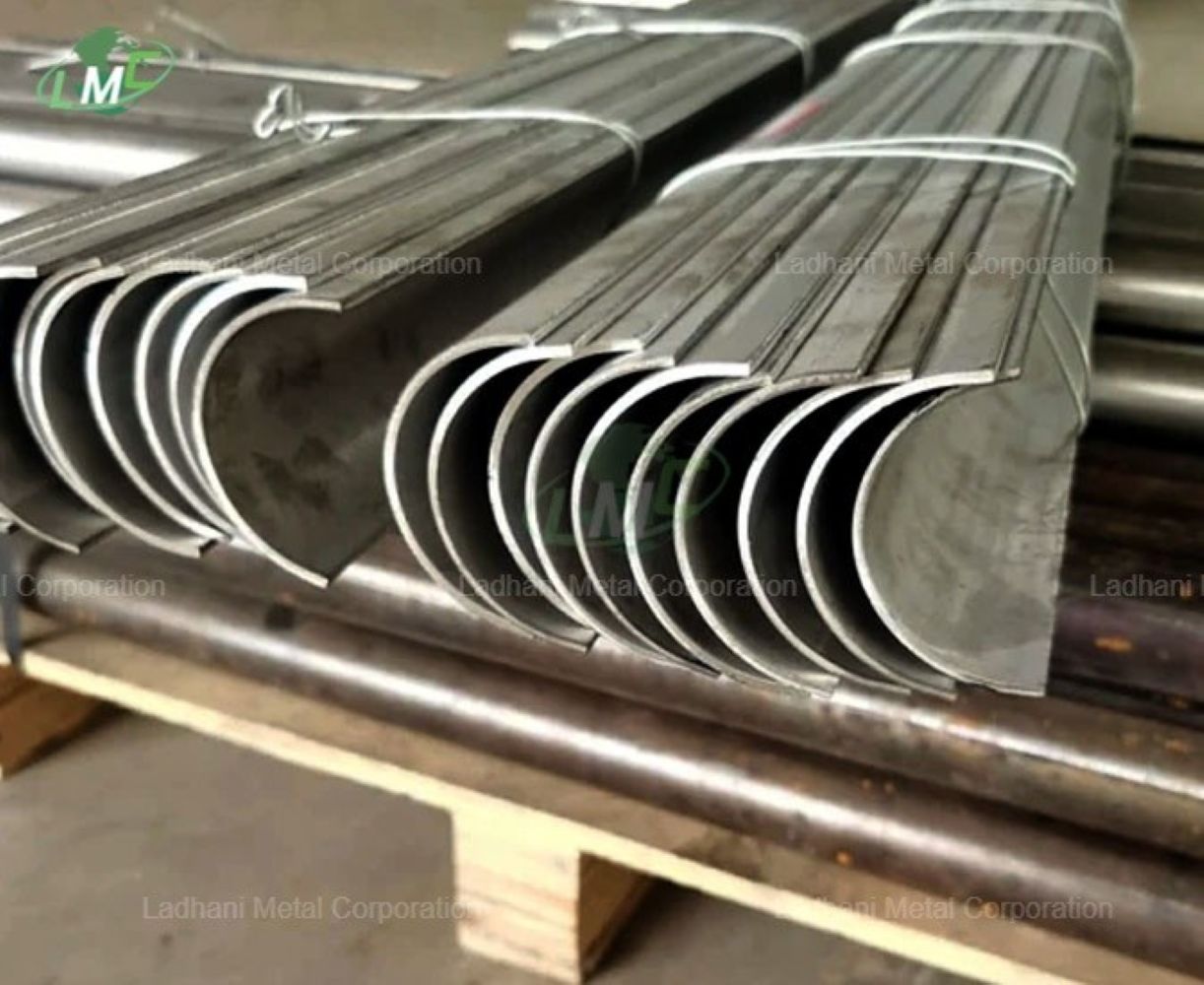

Ladhani Metal Corporation offers 1Cr18Ni9Ti Boiler Half Round Tube Shields engineered to provide robust protection for boiler and heat exchanger tubes against erosion, oxidation, and high-temperature wear. Manufactured from titanium-stabilized austenitic stainless steel, 1Cr18Ni9Ti exhibits excellent corrosion resistance, superior oxidation resistance at elevated temperatures, and enhanced intergranular corrosion resistance due to titanium stabilization. The shields are precision-formed into a half-round profile, ensuring accurate fitment over straight sections of boiler tubes. They act as a physical barrier against abrasive flue gas, particulate erosion, and soot blower impact, thereby extending tube life and minimizing maintenance requirements. Ladhani Metal Corporation manufactures, supplies, and exports 1Cr18Ni9Ti Boiler Half Round Tube Shields in various lengths, diameters, and thicknesses, catering to both domestic and international markets. 1Cr18Ni9Ti Grade Chemical Composition – Titanium Stabilized Austenitic Stainless Steel • Carbon (C): ≤ 0.12% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 17.00 – 19.00% • Nickel (Ni): 8.00 – 11.00% • Titanium (Ti): ≥ 5 × C% • Iron (Fe): Balance Applications: Designed for thermal power plants, waste heat recovery boilers, HRSGs, and industrial boiler systems operating in high-temperature and mildly corrosive conditions. Uses • Shields straight boiler tubes in superheaters and reheaters • Protects against high-temperature oxidation and scaling • Reduces erosion from particulate-laden flue gases • Suitable for waste heat recovery and industrial furnace systems Features • High-temperature performance – Maintains strength and stability at elevated service temperatures • Titanium stabilization – Prevents intergranular corrosion and prolongs service life • Excellent oxidation resistance – Suitable for long-term dry heat exposure • Precision-formed fit – Matches tube curvature for effective coverage • Versatile installation – Can be welded, clamped, or banded as per site requirements • Export quality – Manufactured in compliance with global standards Applications • Thermal power generation – Guards steam and boiler tubes against oxidation and scaling • HRSGs and WHRBs – Provides long-term wear protection in heat recovery systems • Petrochemical heaters – Suitable for oxidizing and mildly corrosive gas conditions • Industrial process heating – Used in cement, chemical, and food industries for tube protection Conclusion The 1Cr18Ni9Ti Boiler Half Round Tube Shield from Ladhani Metal Corporation is a high-performance tube protection solution for boilers and heat exchangers operating in high-temperature and oxidizing environments. With titanium stabilization, excellent corrosion resistance, and long-term thermal stability, these shields are ideal for extending tube service life while reducing maintenance downtime. Available in custom sizes and export-ready configurations, they are suitable for a wide range of industrial applications worldwide. For technical specifications or export inquiries, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur#halftubeshield #utypehalftubeshield #tubeshieldexporter #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions

Send Message