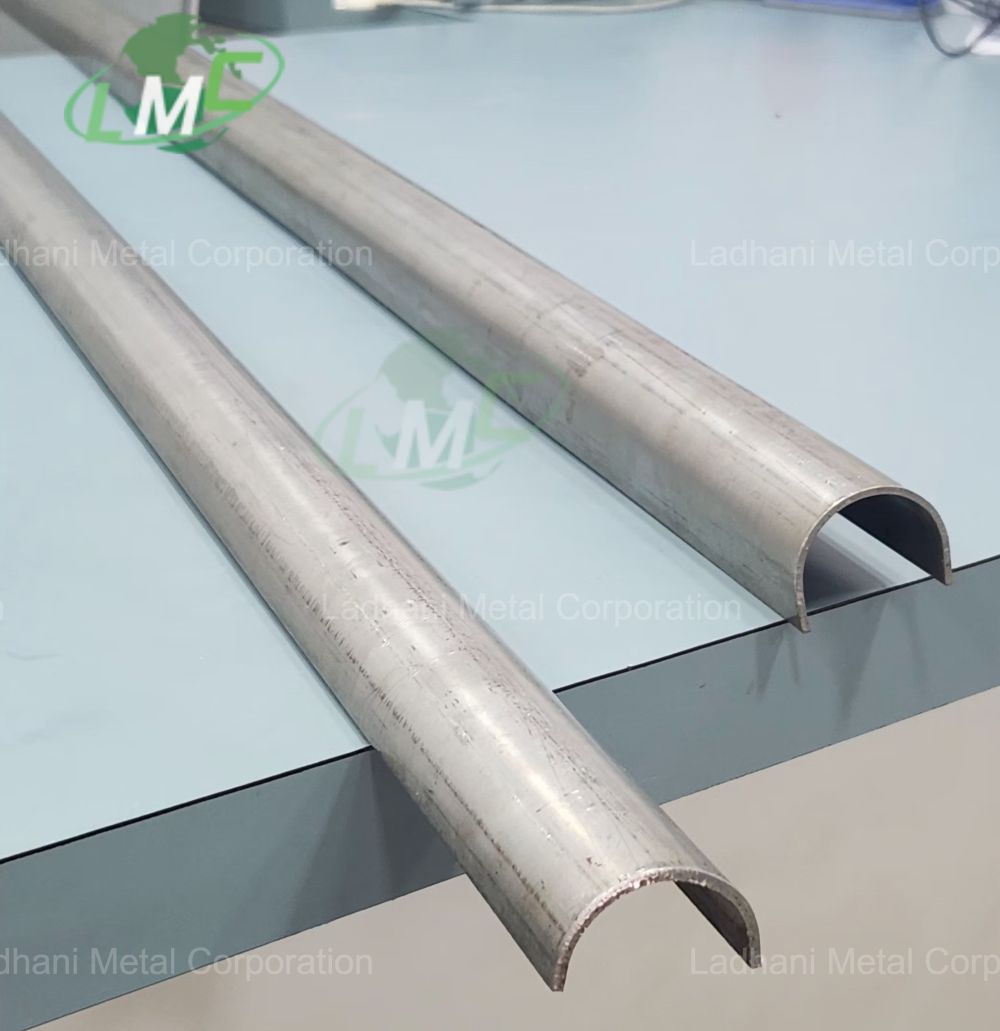

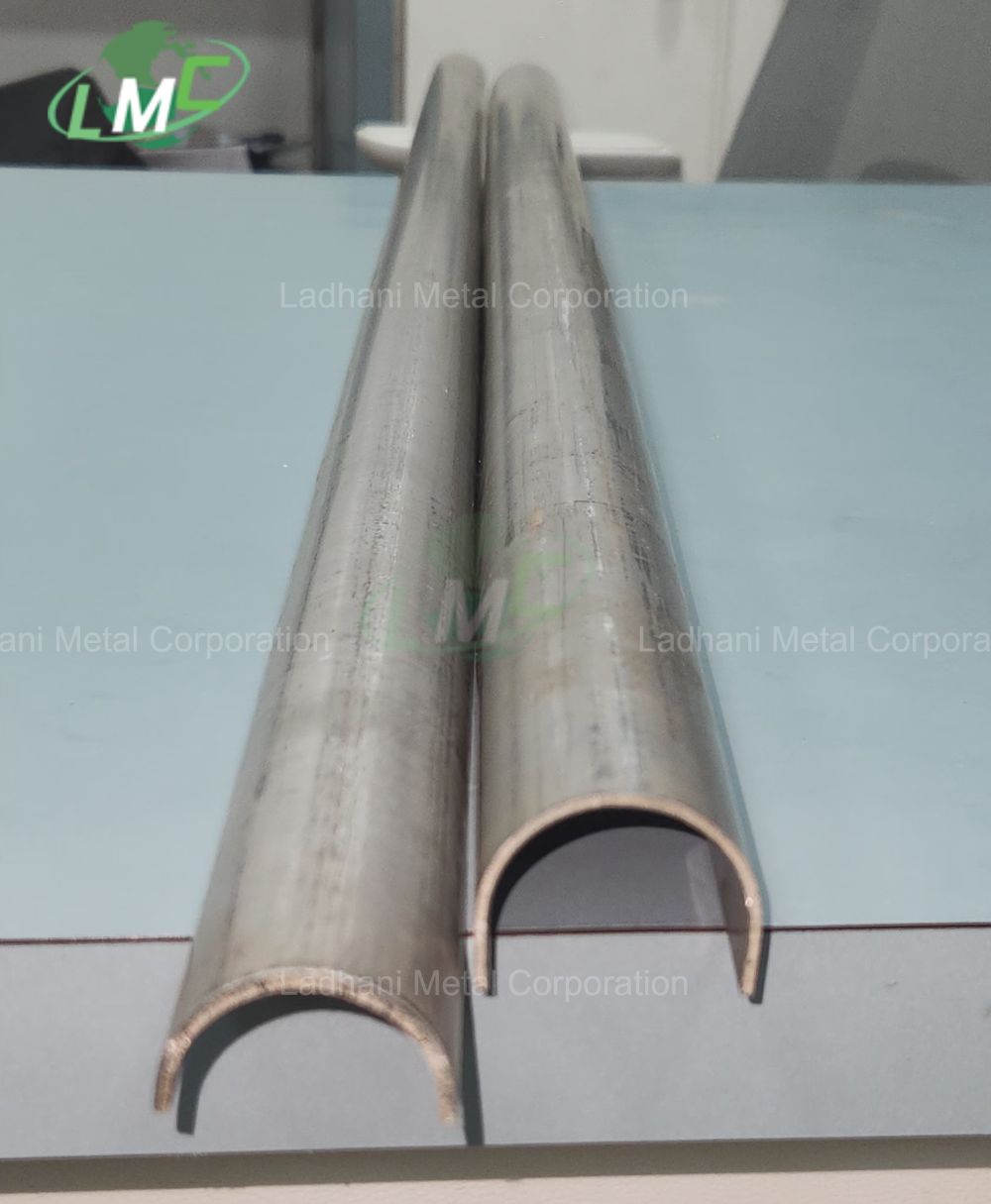

U Type Half Round Tube Shield

Half Round Tube Shield

Half Round Tube Shields by Ladhani Metal Corporation are precision-engineered components used to protect boiler and heat exchanger tubes from erosion, scaling, and high-temperature corrosion. These shields are widely applied in industrial systems exposed to thermal cycling, aggressive gases, and particulate flow. Their half-round shape allows for simple and secure installation over straight or curved tube surfaces, extending tube life and reducing maintenance needs.

1Cr25Ni20Si2 U Type Half Round Tube Shield

The 1Cr25Ni20Si2 U Type Half Round Tube Shield is specifically designed for use in extreme high-temperature environments where oxidation, carburization, and thermal fatigue are major concerns. Fabricated from 1Cr25Ni20Si2, a high-chromium, high-nickel austenitic heat-resistant alloy with added silicon, this shield provides superior resistance to scaling, thermal deformation, and chemical attack. It is ideal for protecting U-bend sections in superheaters, reformers, and waste heat recovery systems operating under aggressive thermal and gas flow conditions.

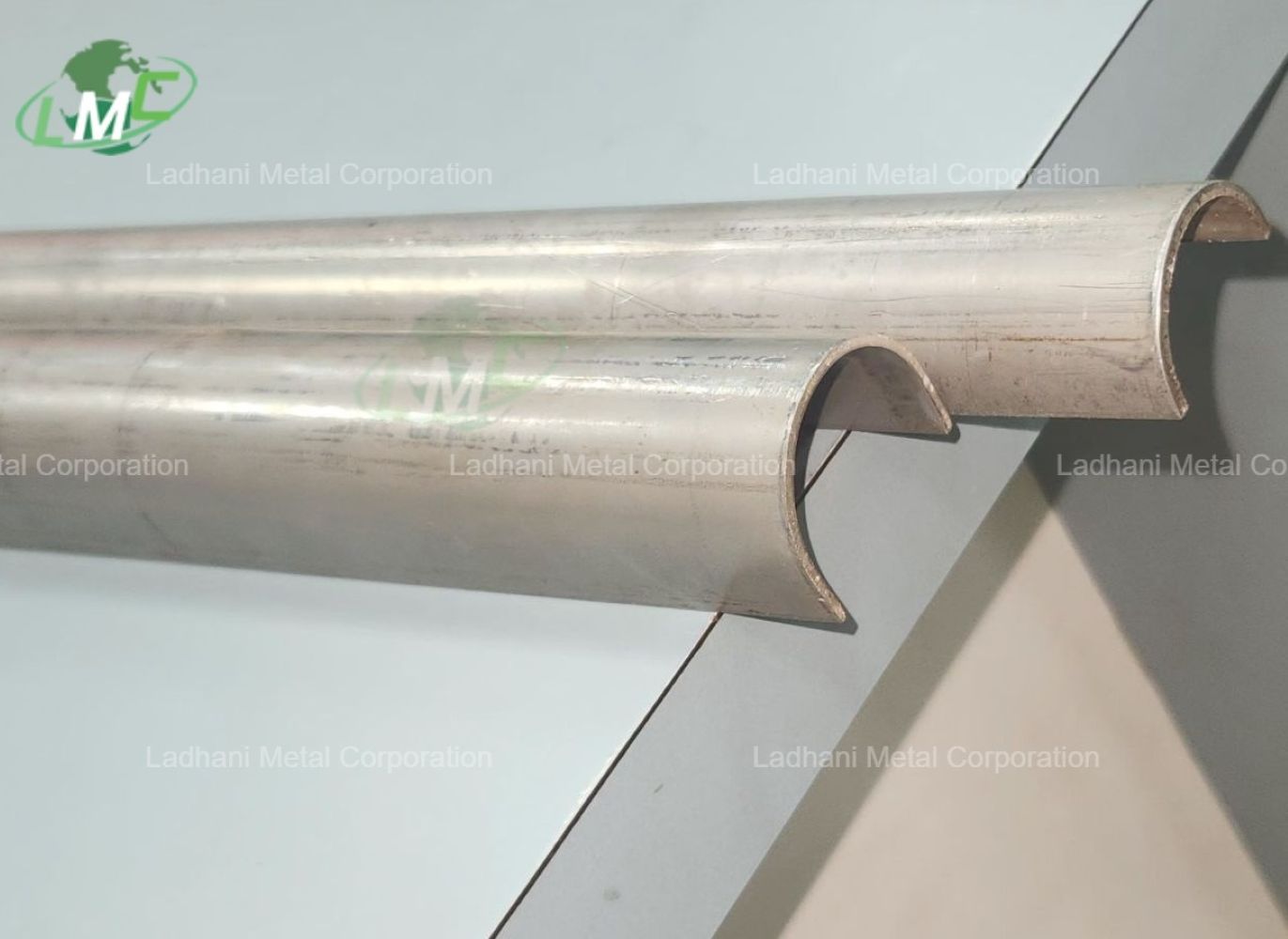

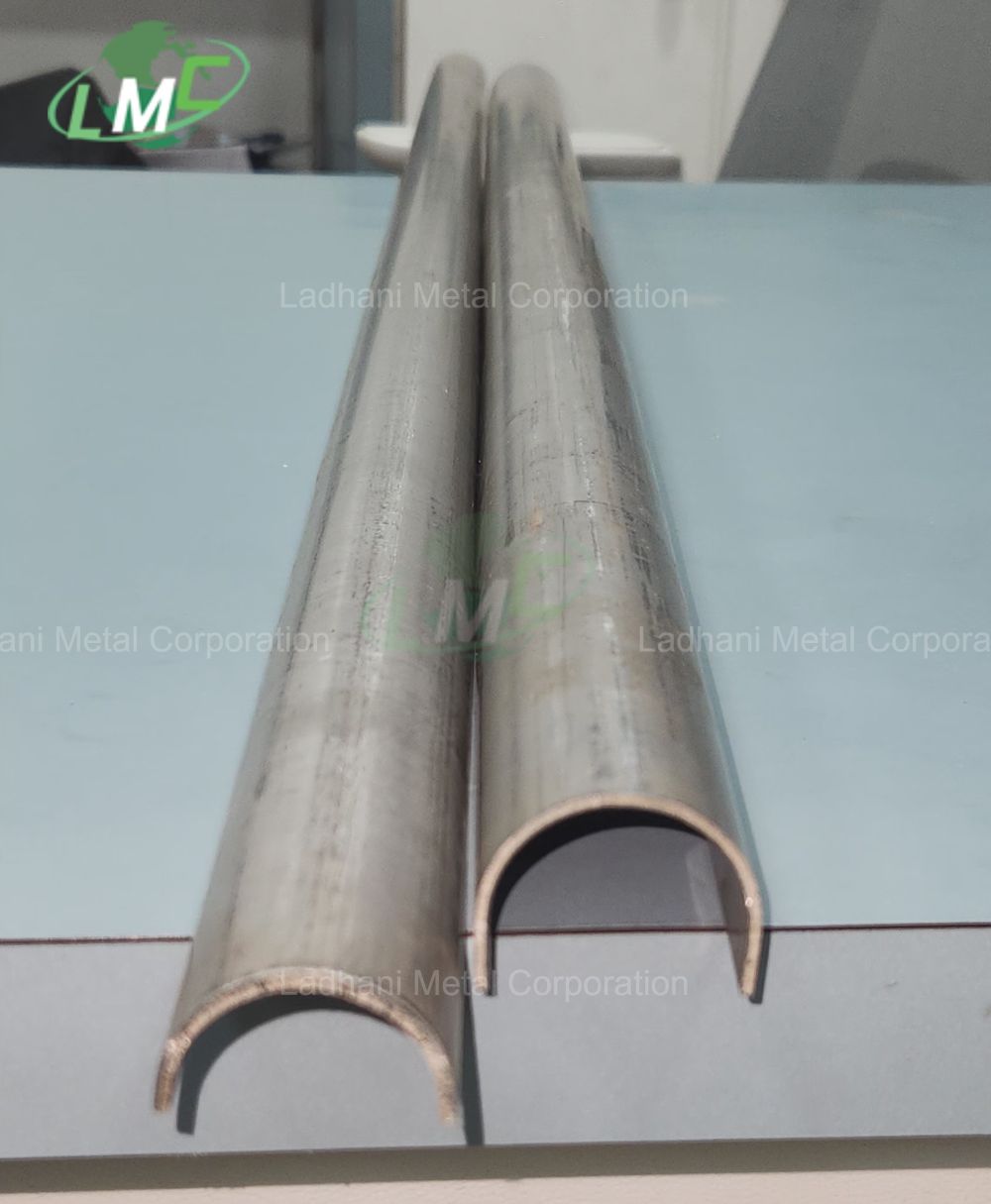

• Outer U Type Half Round Tube Shield – Defends the outer curvature of U-bends from flame impingement, slag buildup, and high-temperature oxidation.

• Inner U Type Half Round Tube Shield – Shields the inner arc from turbulence-driven erosion, localized thermal stress, and scaling in cyclic heating zones.

Ladhani Metal Corporation offers 1Cr25Ni20Si2 U Type Half Round Tube Shields for industries that demand long-term durability, high-temperature performance, and chemical resistance in critical tube bend applications.

Chemical Composition of 1Cr25Ni20Si2 – High-Temperature Austenitic Stainless Steel

• Carbon (C): ≤ 0.20%

• Manganese (Mn): ≤ 1.50%

• Phosphorus (P): ≤ 0.035%

• Sulfur (S): ≤ 0.030%

• Silicon (Si): 1.00 – 2.50%

• Chromium (Cr): 24.0 – 26.0%

• Nickel (Ni): 19.0 – 22.0%

• Iron (Fe): Balance

Applications: Best suited for high-temperature, oxidizing, and carburizing environments such as petrochemical reformers, thermal reactors, and industrial boilers.

Uses

• Protection of U-bend tubes in superheaters and reheaters in thermal and captive power plants

• Shielding tube bends in waste heat recovery boilers (WHRBs) and HRSGs subjected to slag and heat erosion

• Guarding return bends in petrochemical steam reformers and cracking furnaces

• Coverage for curved tubes in chemical reactors exposed to oxidizing and acidic gases

• Ideal for industrial plants where prolonged exposure to thermal cycling and aggressive gas media is common

Features

• High-temperature strength – Maintains mechanical integrity and structural stability in service temperatures exceeding 1000°C.

• Superior oxidation resistance – High chromium and silicon content offers excellent protection against scaling in air and oxidizing environments.

• Carburization resistance – Resists carbon infiltration in environments rich in hydrocarbons and flue gases.

• Full U-bend shielding – Available in both inner and outer U-type configurations for complete coverage of critical curved tube areas.

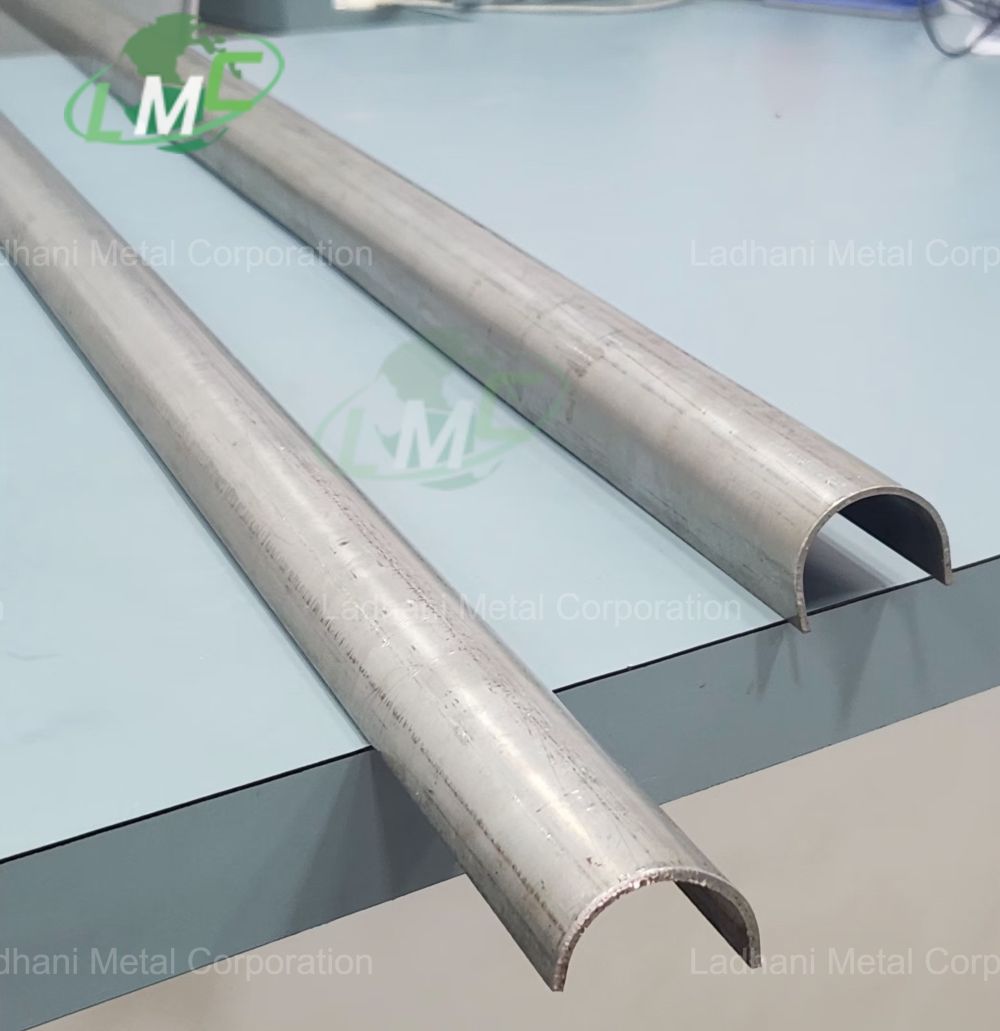

• Custom fabrication – Precisely manufactured to match tube radius, bend angle, and diameter for a secure, vibration-resistant fit.

• Easy to install – Mountable using clamps, bands, or tack welds without the need for system disassembly or extended shutdown.

Applications

• thermal power stations – Used on U-bend tubes in high-temperature sections of superheaters and reheaters to prevent scaling and heat-related fatigue. Increases equipment life and operational efficiency.

• petrochemical refineries – Installed in steam reformers, cracking furnaces, and heaters exposed to oxidizing and carburizing gases. Delivers consistent protection under continuous heat stress.

• waste heat recovery units – Shields return bends in WHRBs and HRSGs from slag abrasion and flue gas corrosion. Enhances resistance to thermal cycling.

• chemical and metallurgical plants – Ideal for reactors, synthesis gas units, and process heat exchangers operating under severe thermal and chemical loads.

• cement and glass industries – Applied in high-temperature gas flow lines and heater tubes where scale resistance and mechanical protection are essential.

Conclusion

The 1Cr25Ni20Si2 U Type Half Round Tube Shield by Ladhani Metal Corporation is a high-performance shielding solution engineered for extreme temperature and chemically aggressive environments. With its superior resistance to oxidation, carburization, and thermal fatigue, this alloy-based shield is ideal for power generation, petrochemical, and heavy industrial applications. Custom-fit for precision and ease of use, it offers long service life, reliability, and protection for the most demanding tube bend installations.

For technical consultation, custom orders, or quotations, please contact Ladhani Metal Corporation.

Send Message