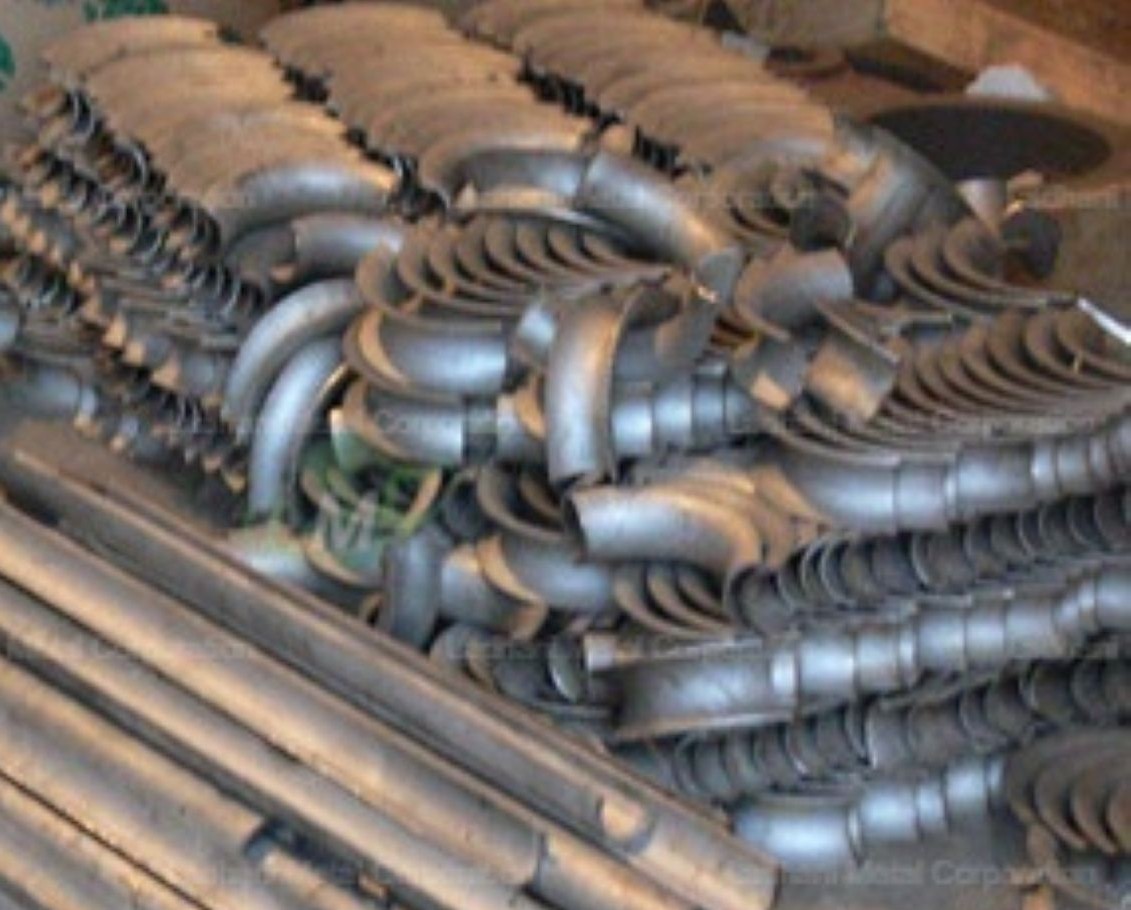

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are precision-engineered components used to protect boiler and heat exchanger tubes from erosion, scaling, and high-temperature corrosion. These shields are widely applied in industrial systems exposed to thermal cycling, aggressive gases, and particulate flow. Their half-round shape allows for simple and secure installation over straight or curved tube surfaces, extending tube life and reducing maintenance needs. SS 310S U Type Outer Half Round Tube Shield The SS 310S U Type Outer Half Round Tube Shield is designed using SS 310S, a low-carbon austenitic stainless steel known for its excellent resistance to oxidation, high-temperature strength, and enhanced weldability. This outer U-type shield is specifically engineered to cover and protect the outer arc of U-bend tube sections in superheaters, reheaters, waste heat recovery systems, and high-temperature heat exchangers. With its high chromium and nickel content, SS 310S provides superior performance in oxidizing and carburizing environments while maintaining structural stability during prolonged thermal cycling. • Outer U Type Half Round Tube Shield – Shields the external curvature of U-bend tubes from slag deposition, hot gas erosion, scale formation, and high-temperature fatigue. Ladhani Metal Corporation is a leading manufacturer, supplier, and exporter of SS 310S U Type Outer Half Round Tube Shields, offering high-performance solutions for critical thermal and process applications across industries. Chemical Composition of SS 310S – Low-Carbon Austenitic Stainless Steel • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.50% • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 19.0 – 22.0% • Iron (Fe): Balance Applications: Best suited for high-temperature, oxidizing, and carburizing environments where thermal stability, scale resistance, and corrosion protection are essential. Uses • Outer surface protection of U-bend tubes in superheaters and reheaters of thermal and industrial power plants • Shielding of return bends in petrochemical reformers, process heaters, and high-temperature exchangers • Applied to outer arcs in WHRBs and HRSGs subjected to thermal cycling, slag erosion, and hot flue gas exposure • Suitable for use in chemical and gas processing units handling oxidizing or acidic exhausts at elevated temperatures • Ideal for incinerator tubes, radiant coils, and furnace bends operating under continuous or cyclic heat conditions Features • Outstanding high-temperature strength – Performs effectively up to 1150°C with excellent resistance to scaling and oxidation • Enhanced weldability – Low carbon content minimizes the risk of sensitization and intergranular corrosion after welding • Outer U-bend coverage – Designed for targeted protection where erosion and thermal impact are most severe • Precision fitment – Manufactured to exact tube radius and diameter specifications for tight, vibration-free installation • Quick installation – Easily mounted using clamps, tack welds, or stainless steel banding without system disassembly • Long-term durability – Resistant to cracking, scaling, and corrosion under thermal fatigue, reducing maintenance and downtime Applications • thermal power plants – Installed on U-bend tube outer curves in superheaters and reheaters for oxidation and erosion protection • petrochemical plants – Used in reformers and cracking furnaces exposed to high-temperature and oxidizing environments • waste heat recovery systems – Protects return bends in WHRBs and HRSGs from hot gas flow, slag buildup, and scaling • chemical and gas processing – Shields bends in high-temperature exchangers and preheaters from corrosive and oxidizing media • furnaces and industrial incinerators – Applied to radiant tubes and burner bends subjected to direct flame and thermal cycling Conclusion The SS 310S U Type Outer Half Round Tube Shield by Ladhani Metal Corporation—manufacturer, supplier, and exporter—is a premium solution for protecting U-bend tube outer arcs in boilers and heat exchangers exposed to severe heat and gas flow conditions. With excellent oxidation resistance, low carbon content for improved weldability, and precision design for long-lasting performance, this shield enhances the lifespan and reliability of thermal systems across a wide range of industrial sectors. For technical consultation, custom orders, or quotations, please contact Ladhani Metal Corporation.

Send Message